A 3D paving construction technology for asphalt pavement

A technology of asphalt pavement and construction technology, applied in the field of 3D paving construction technology of asphalt pavement, can solve the problems of erection reference deviation, increase construction errors and accidents, engineering quality and safety hazards, etc., and reduce mixing temperature and spread. Laying temperature, inhibiting the release of harmful gases, reducing the effect of use and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

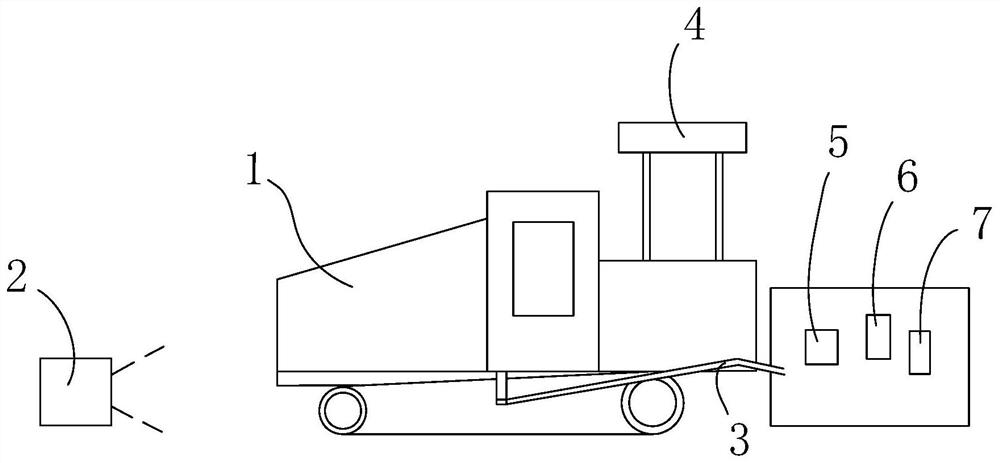

[0037] A kind of 3D paving construction technology of asphalt pavement is to utilize the paving machine that is equipped with 3D paving automatic control system to carry out automatic control paving construction, described 3D paving automatic control system, such as figure 1 As shown, it includes a three-dimensional position positioning system and a vehicle-mounted control system installed on the paver 1;

[0038] The three-dimensional position positioning system is configured with three Robot61 total stations 2, of which two mechanical control total stations are mainly used to guide the on-site construction of the 3D paving automatic control system, and the other measurement total station is used for real-time detection of paving Face-to-design face offset and "leapfrogging" during paving.

[0039] The vehicle-mounted control system includes a main controller 6 with 3D paving auxiliary software, two side control boxes 7, two 360° prisms 3, a slope sensor 5, and two vehicle-mo...

Embodiment 2

[0062] A kind of 3D paving construction technology of asphalt pavement is basically the same as embodiment 1, wherein the paving raw material preparation of step (1) is specifically as follows:

[0063] Mix the asphalt, aggregate and warm mix agent uniformly, and the mixing temperature is 100°C to obtain the asphalt paving composition;

[0064] The addition amount of described warm mixing agent is 2% of the total weight of asphalt and aggregate, and described warm mixing agent is made up of the raw material of following parts by weight: rosin glycerin resin 50 parts, ozokerite 20 parts, acrylate 3 parts, four 5 parts of ethylene pentamine.

[0065] The acrylate is ethoxyethyl acrylate.

[0066] The preparation method of the warm mixing agent is as follows: Weigh ceresine wax and rosin glycerin resin in parts by weight, heat the rosin glycerin resin to 115° C., add ozokerite, stir at 800 r / min for 20 minutes, keep warm at 105° C. for 1.5 hours, and Add acrylate and tetraethyl...

Embodiment 3

[0068] A kind of 3D paving construction technology of asphalt pavement is basically the same as embodiment 1, wherein the paving raw material preparation of step (1) is specifically as follows:

[0069] Mix the asphalt, aggregate and warm mix agent uniformly, and the mixing temperature is 110°C to obtain the asphalt paving composition;

[0070] The addition of the warm mixing agent is 3% of the total weight of asphalt and aggregate, and the warm mixing agent is made up of the following raw materials in parts by weight: 70 parts of rosin glycerin resin, 30 parts of ozokerite, 6 parts of acrylate, four 10 parts of ethylene pentamine.

[0071] The acrylate is 2-phenoxyethyl acrylate.

[0072] The preparation method of the warm mixing agent is as follows: Weigh ceresine wax and rosin glycerin resin in parts by weight, heat the rosin glycerin resin to 120°C, add ozokerite, stir at 600r / min for 30min, and keep warm at 110°C for 1h while stirring While adding acrylate and tetraethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com