Novel dry distillation device based on gas combustion principle

A new type of dry distillation technology, applied in special forms of dry distillation, indirect heating dry distillation, petroleum industry, etc., can solve the problems of dry distillation and pyrolysis devices that cannot be applied to the current situation and wet coke discharge methods, and achieve the improvement of jet flow disturbance, Smooth movement and less sticking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

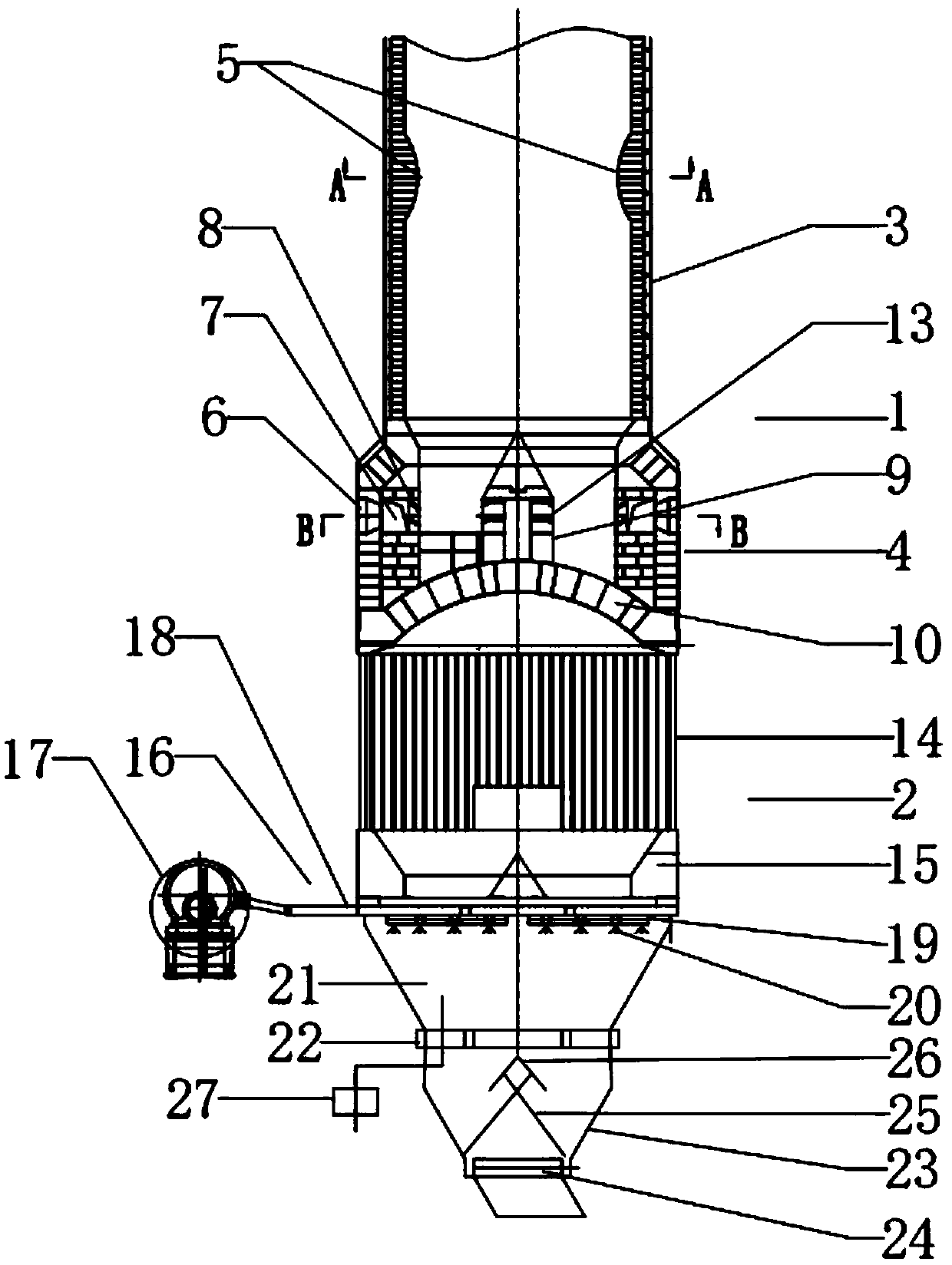

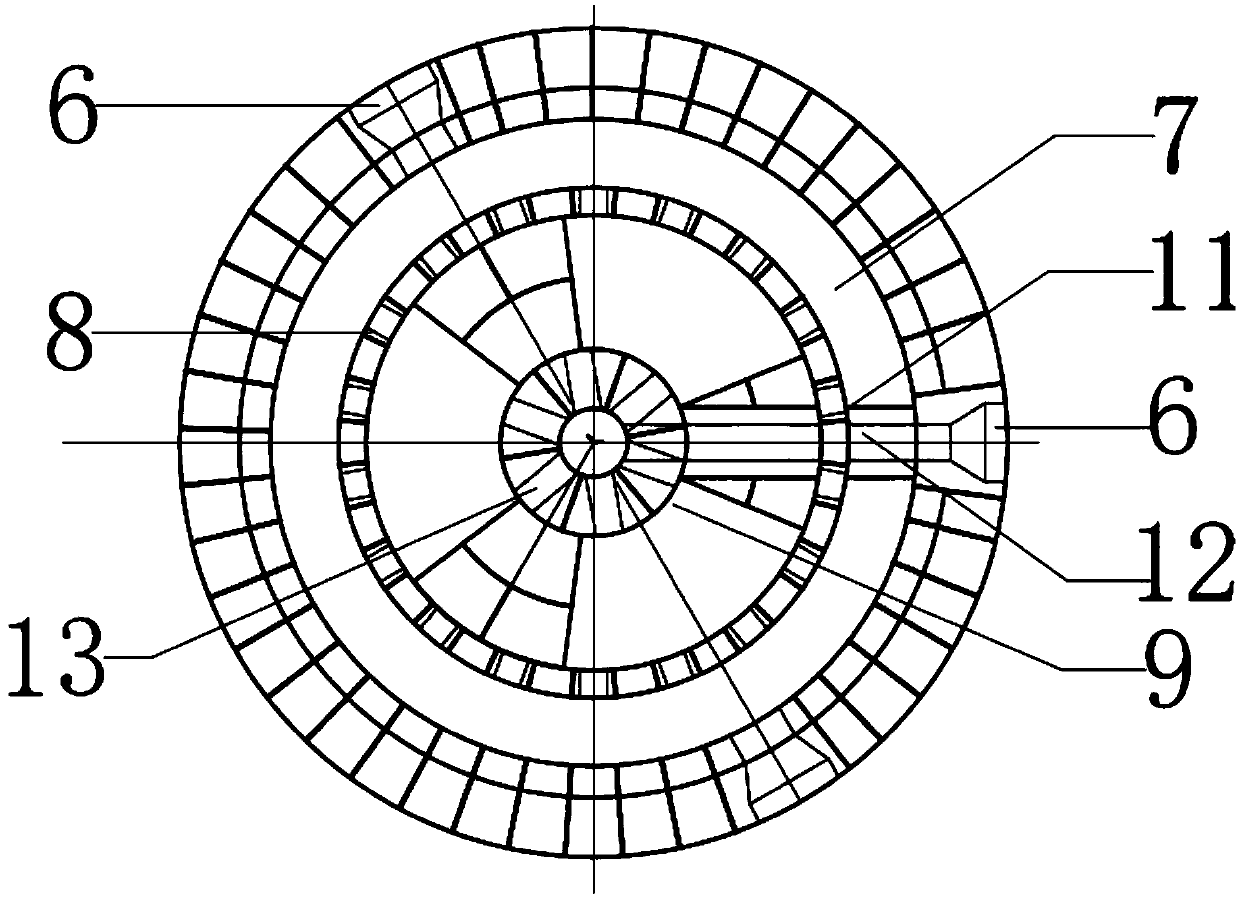

[0050] Such as Figure 1~4 As shown, a new type of retort device based on the principle of gas combustion, including an upper retort furnace 1 and a lower coke discharge device 2, a gate valve is provided between the retort furnace and the coke discharge device, and the retort furnace is cylindrical , the dry distillation furnace includes an upper low-temperature dry distillation section 3 and a lower high-temperature dry distillation section 4;

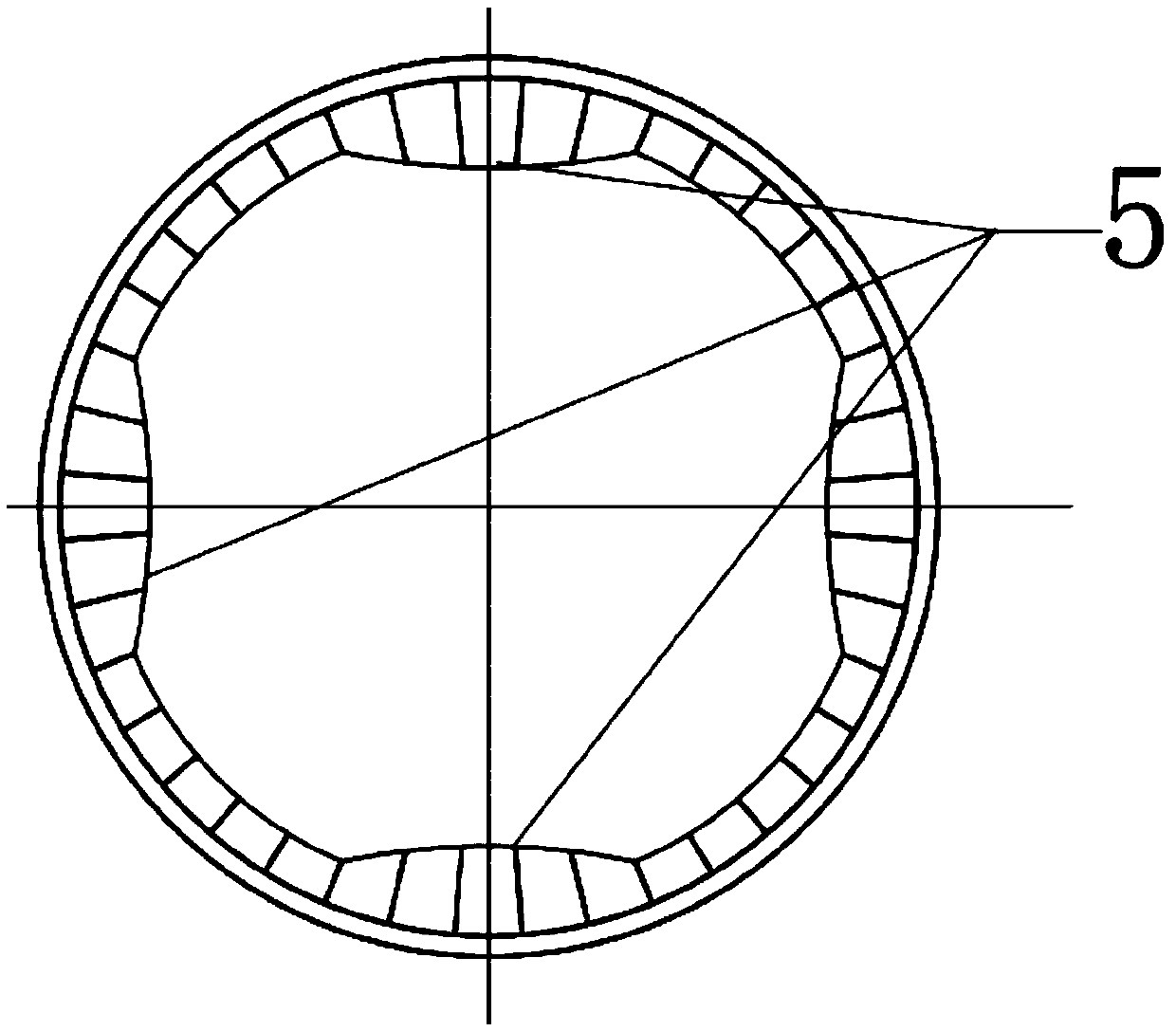

[0051] The inner wall of the low-temperature retort section is provided with four disturbance walls protruding inward and evenly distributed along the inner wall. The disturbance walls are arranged symmetrically along the inner wall of the furnace, and the inner end surfaces of the disturbance walls are str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com