A kind of slag porous glass-ceramic and its preparation method

A technology of porous glass-ceramics and slag, which is applied in the field of solid waste resource utilization, can solve the problems of difficult control of pore size, poor thermal conductivity, and poor uniformity of pores, so as to save processing costs, solve difficult-to-handle problems, and improve thermal insulation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

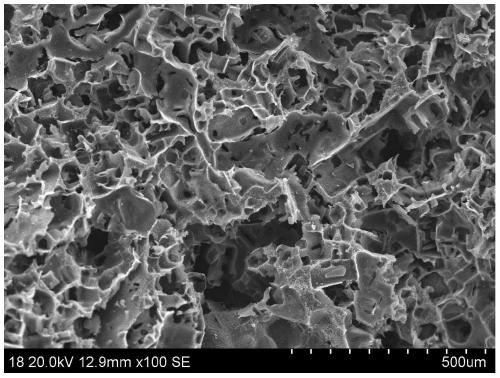

Image

Examples

Embodiment 1

[0048] A kind of slag porous glass-ceramic, its raw material according to proportion, basic glass powder: granulated sugar = 1.0, sodium chloride: basic glass powder = 0.7; described basic glass powder, its raw material according to weight percentage, SiO 2 43%, CaO 29%, Fe 2 o 3 5.1%, Cr 2 o 3 0.4%, Al 2 o 3 10%, Borax 4%, MgO 5.5%, Fluorite 3%.

[0049] The steps of the method for preparing the slag porous glass-ceramics include:

[0050] (1) Mixing: according to the ratio of raw materials, weigh stainless steel slag, iron tailings, Al 2 o 3 , borax, MgO, fluorite, mixed evenly, mixing time 30min;

[0051] (2) Preparation of basic glass: put the mixed raw materials into a crucible, heat and melt for 3 hours, and the melting temperature is 1400°C, quickly pour the melted glass into cold water to obtain basic glass particles, and dry them;

[0052] (3) Preparation of basic glass powder: Grinding the dried basic glass particles with a ball mill into a particle size o...

Embodiment 2

[0062] A kind of slag porous glass-ceramic, its raw material according to proportioning, basic glass powder: granulated sugar=1.1, sodium chloride: basic glass powder=0.6; Said basic glass, its raw material according to weight percentage, SiO 2 50%, CaO 31%, Fe 2 o 3 5%, Cr 2 o 3 1%, Al 2 o 3 5%, Borax 3%, MgO 3%, Fluorite 2%.

[0063] The steps of the method for preparing the slag porous glass-ceramics include:

[0064] (1) Mixing: according to the ratio of raw materials, weigh stainless steel slag, iron tailings, Al 2 o 3 , borax, MgO, fluorite, mixed evenly, mixing time 30min;

[0065] (2) Preparation of basic glass: Put the mixed raw materials into a crucible, heat and melt for 2 hours, the melting temperature is 1450°C, quickly pour the melted glass into cold water to obtain basic glass particles, and dry them;

[0066] (3) Preparation of basic glass powder: Grinding the dried basic glass particles with a ball mill into a particle size of -200 mesh basic glas...

Embodiment 3

[0076] A kind of slag porous glass-ceramic, its raw material according to proportion, basic glass powder: flake sugar = 1.2, potassium chloride: basic glass powder = 0.8; described basic glass, its raw material according to weight percentage, SiO 2 50%, CaO 24%, Fe 2 o 3 8%, Cr 2 o 3 2.5%, Al 2 o 3 6.5%, Borax 2%, MgO 3%, Fluorite 4%.

[0077] The steps of the method for preparing the slag porous glass-ceramics include:

[0078] (1) Mixing: according to the ratio of raw materials, weigh stainless steel slag, iron tailings, Al 2 o 3 , borax, MgO, fluorite, mixed evenly, mixing time 30min;

[0079] (2) Preparation of basic glass: put the mixed raw materials into a crucible, heat and melt for 3 hours, and the melting temperature is 1350°C, quickly pour the melted glass into cold water to obtain basic glass particles, and dry them;

[0080] (3) Preparation of basic glass powder: Grinding the dried basic glass particles with a ball mill into a particle size of -200 mes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com