A new type of "sandwich" structure flexible hot film microsensor and its manufacturing method

A micro-sensor and sandwich technology, applied in the field of micro-electromechanical systems, can solve the problems that restrict the improvement of sensor measurement accuracy and dynamic characteristics, and are not completely eliminated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

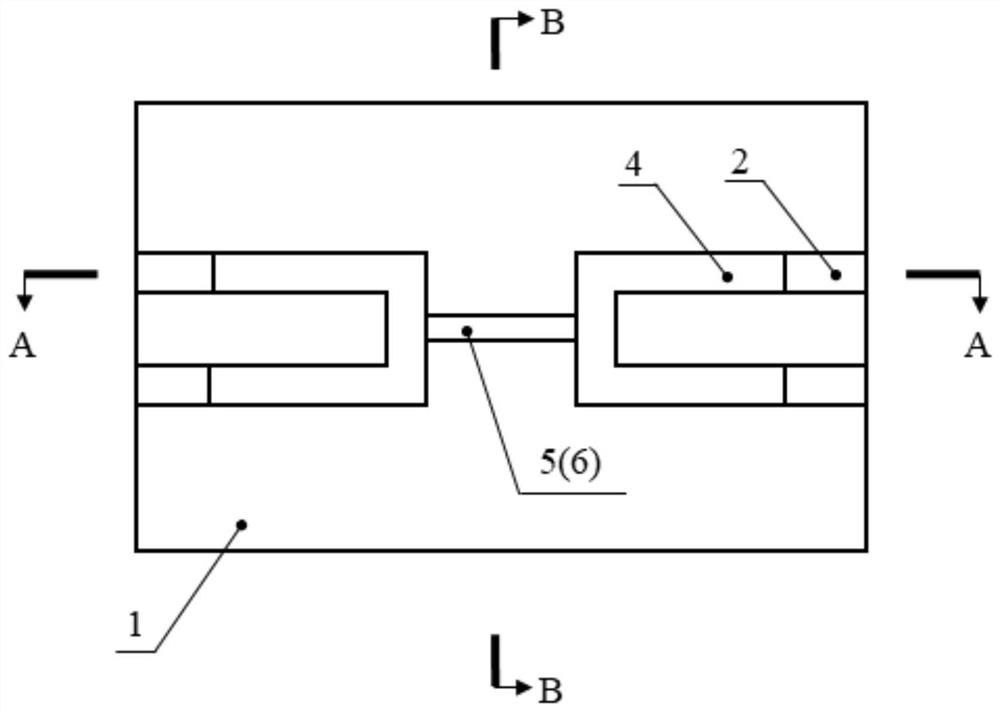

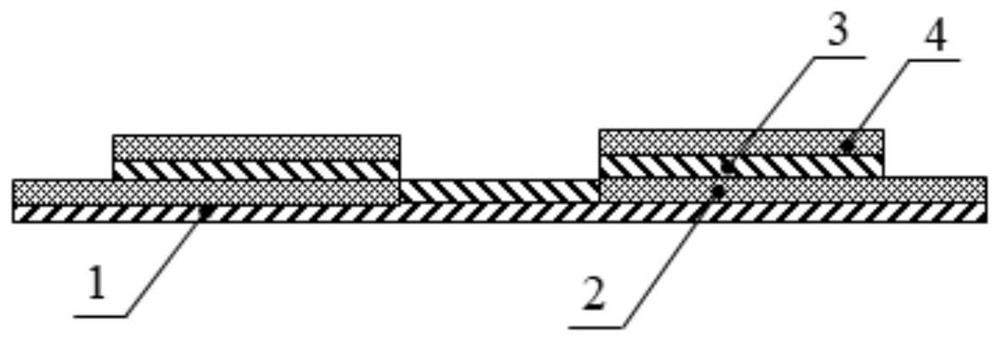

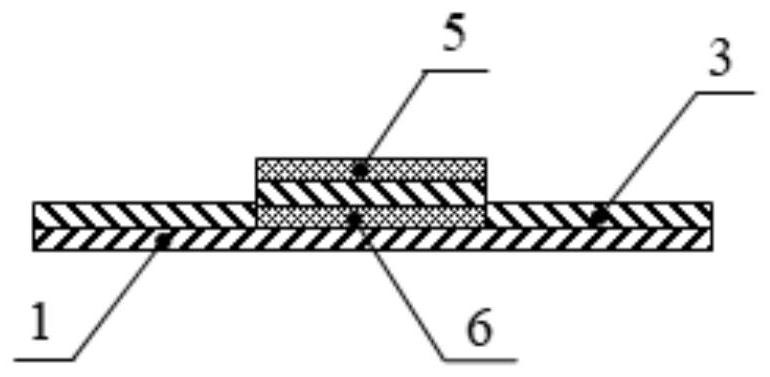

[0026] In this embodiment, the novel "sandwich" structure flexible thermal film microsensor includes a "sandwich" structure of a flexible substrate 1 and three layers of thin films on the substrate, and is characterized in that the "sandwich" structure is a top thermal unit 5- The three-layer film structure of the middle insulating layer 3-the bottom heating unit 6; in this embodiment, the top thermal unit 5 and the bottom heating unit 6 are nickel thin films with a thickness of 1 micron, and the top thermal unit 5 is used for Measuring the wall shear stress, the bottom heating unit 6 is used to eliminate the heat conduction from the top thermal unit 5 to the base; the top thermal unit 5 and the bottom heating unit 6 are electrically isolated by an intermediate insulating layer 3 and work independently of each other. Among them, the middle insulating layer 3 is C-type parylene (Parylene C) with a thickness of 5 microns; the top thermal unit 5 and the bottom heating unit 6 have ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com