Thermoplastic film coiling device capable of automatically cutting

An automatic cutting and thermoplastic film technology, applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problem that the thermoplastic film rolling device does not have automatic cutting, saving labor and reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following is further described in detail through specific implementation methods:

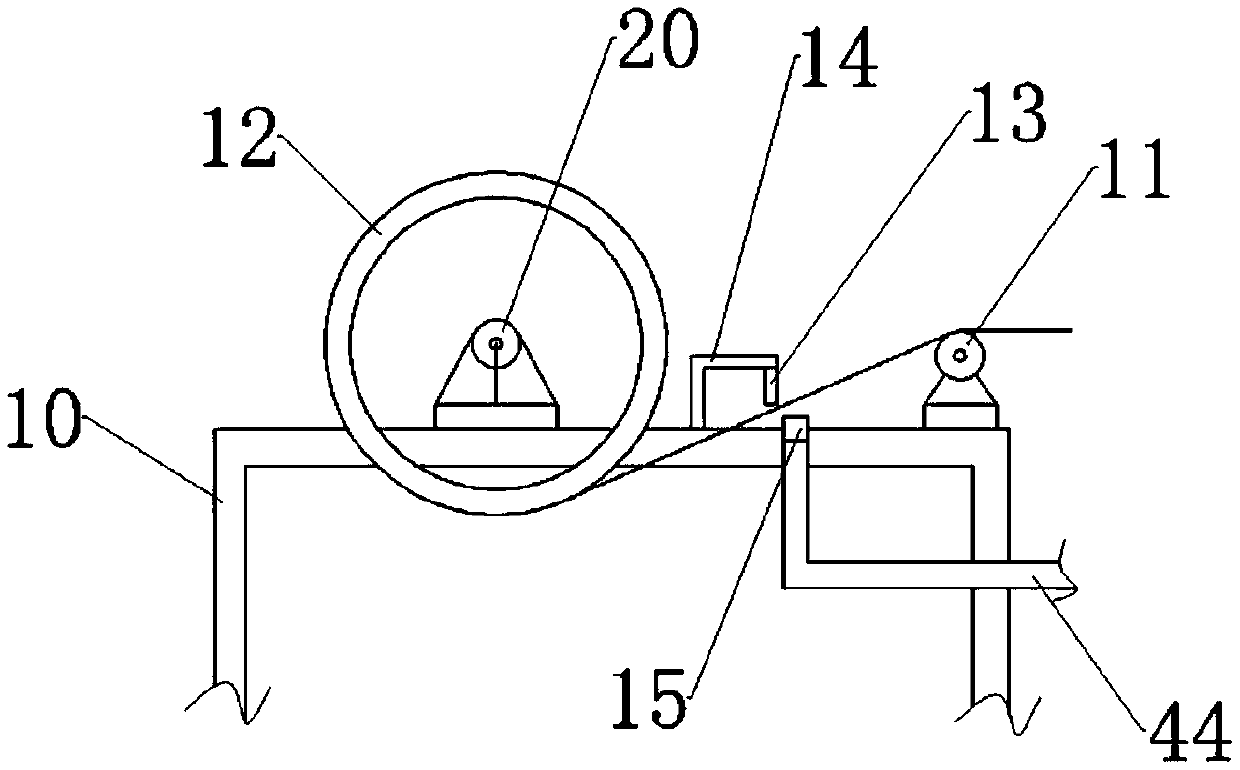

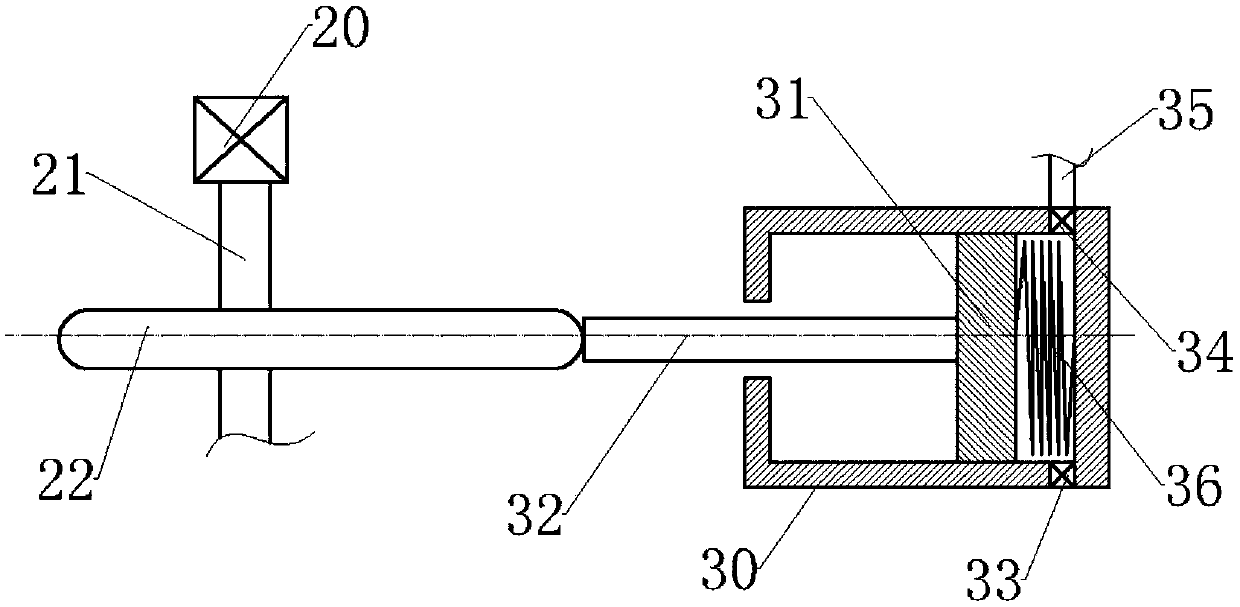

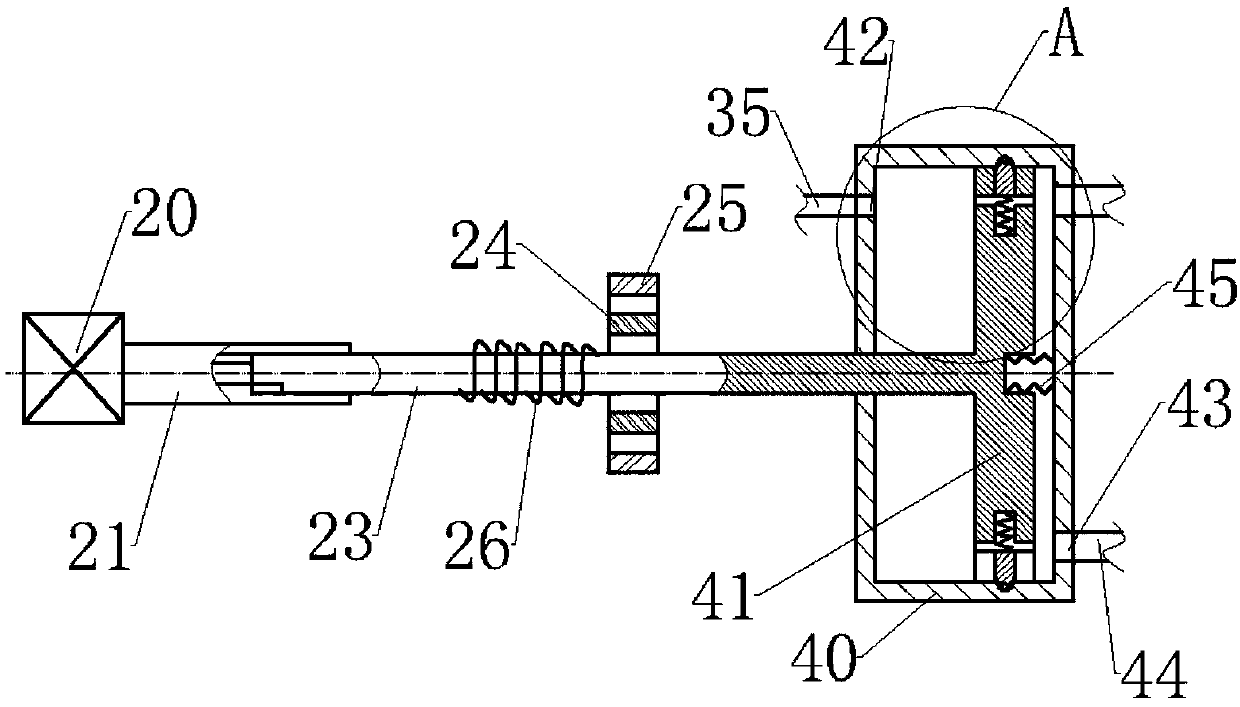

[0031] The reference signs in the accompanying drawings include: bracket 10, transition roller 11, receiving tray 12, cutting knife 13, knife holder 14, air nozzle 15, motor 20, rotating shaft 21, cam 22, connecting rod 23, rotor 24, Stator 25, torsion spring 26, first cylinder 30, first piston 31, first piston rod 32, one-way intake valve 33, one-way outlet valve 34, intake pipe 35, first spring 36, second cylinder 40, the second piston 41, the air intake hole 42, the air outlet hole 43, the air outlet pipe 44, the compression spring 45, the second spring 46, the slide block 47, the steel ball 48.

[0032] A thermoplastic film roll material device that can be automatically cut, such as figure 1 As shown, a bracket 10 is included, and a motor 20 is installed on the bracket 10 . Such as figure 2 As shown, the motor 20 is connected with a rotating shaft 21 . Such as figure 1 As s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com