Coil winding device and control method thereof

A winding device and coil technology, used in coil manufacturing, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problems of coil skeleton pressure skeleton damage, stuck, inaccurate number of coil turns, etc., to solve the problem of coil winding The number of coils is inaccurate, avoiding the sticking and slipping of the winding action, and improving the effect of space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

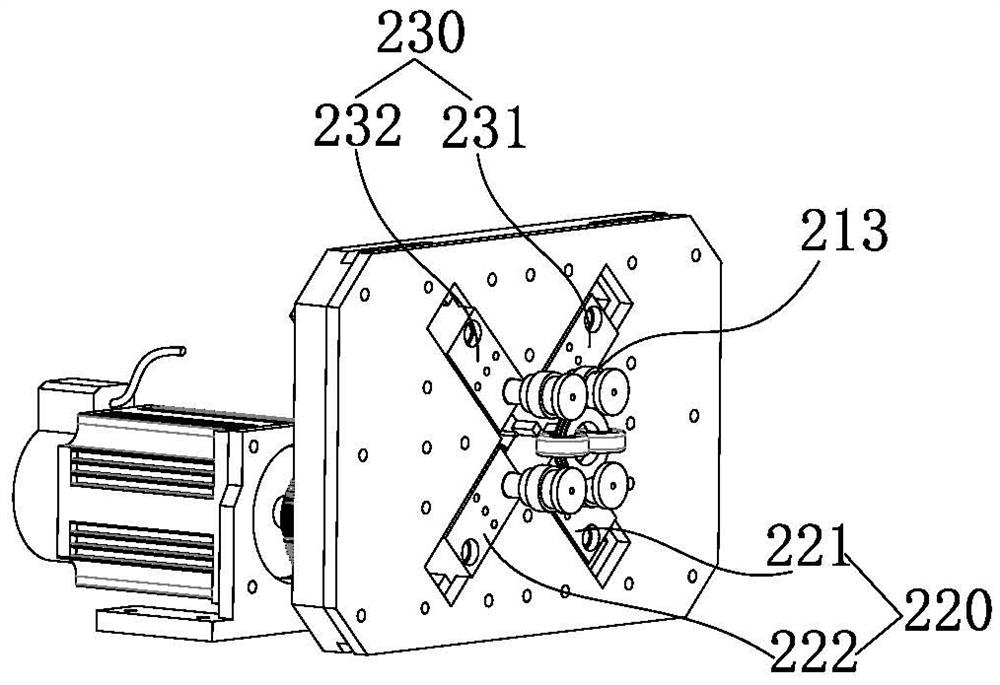

[0054] Such as Figure 1 to Figure 7 As shown, the invention provides a coil winding device, comprising:

[0055] Body 100, and a support plate 110 is provided on the body 100, wherein, the support plate 110 is provided with a vertically arranged line inlet channel 130; the drive mechanism 300 is installed on the body 100, and the output end of the drive mechanism 300 is set There are two driving wheels 212 rotating in the same direction; the sliding mechanism 200 is installed on the support plate 110, and the output end of the sliding mechanism 200 is provided with two driven wheels 211 rotating in the same direction, wherein the driven wheel 211 and the driving wheel The wheel 212 is arranged up and down along the wire-feeding direction of the wire-feed channel 130, and the space between the driven wheel 211 and the driving wheel 212 is used as the clamping space of the skeleton 800 to be wound; The frame 800 is clamped between the driven wheel 211 and the driving wheel 212...

Embodiment 2

[0079] Such as Figure 8 As shown, the present invention also provides a coil winding control method, comprising steps:

[0080] S1: Turn on the power and initialize the device;

[0081] S2: Start the first switch, the first sliding cylinder drives the first sliding plate to move through the first connecting piece, and the second sliding cylinder drives the second sliding plate to move through the second connecting piece, so that the two driven wheels move away from the driving wheel The direction of movement, and the distance between the two driven wheels gradually increases;

[0082] S3: Put the winding skeleton between the two driving wheels and the two driven wheels, and adjust the position;

[0083] S4: Turn off the first switch, the first sliding cylinder drives the first sliding plate to move through the first connecting piece, and the second sliding cylinder drives the second sliding plate to move through the second connecting piece, so that the two driven wheels are...

Embodiment 3

[0087] Such as Figure 9 As shown, the present invention also provides a coil winding control method, comprising steps:

[0088] S1: Turn on the power and initialize the device;

[0089] S2: Start the first switch, the first sliding cylinder drives the first sliding plate to move through the first connecting piece, and the second sliding cylinder drives the second sliding plate to move through the second connecting piece, so that the two driven wheels move away from the driving wheel The direction of movement, and the distance between the two driven wheels gradually increases;

[0090] S3: Put the winding skeleton between the two driving wheels and the two driven wheels, and adjust the position;

[0091] S4: Turn off the first switch, the first sliding cylinder drives the first sliding plate to move through the first connecting piece, and the second sliding cylinder drives the second sliding plate to move through the second connecting piece, so that the two driven wheels are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com