Cyclone type micro-bubble generator and gas-liquid reactor

A technology of micro-bubble generator and gas-liquid reactor, which is applied in chemical methods, fluid mixers, chemical/physical/physical-chemical stationary reactors for reacting liquid and gas medium, etc., can solve the problem of bubble size dispersion. , difficult to manufacture, high energy consumption, to achieve the effect of reduced bubble size, simple structure and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment adopts as figure 1 The microbubble generating device shown is used to prepare microbubbles. Among them, the number of liquid inlet pipes is 2, the diameter is 6mm, and the length is 30mm. Air is used as the gas experiment medium, and water is used as the liquid experiment medium. Air velocity at the air inlet u g =0.24m / s, the liquid velocity at the throat increased from 0.32m / s equivalent to 1.6m / s, and the bubbles generated by the microbubbles were photographed with a high-speed camera, and the statistically obtained microbubble fraction changes with the liquid velocity as follows: Figure 7 As shown, it can be seen from the figure that when the throat liquid velocity is greater, the microbubble fraction is higher, and when the throat liquid velocity u l =1.6m / s, microbubble fraction η=65%.

Embodiment 2

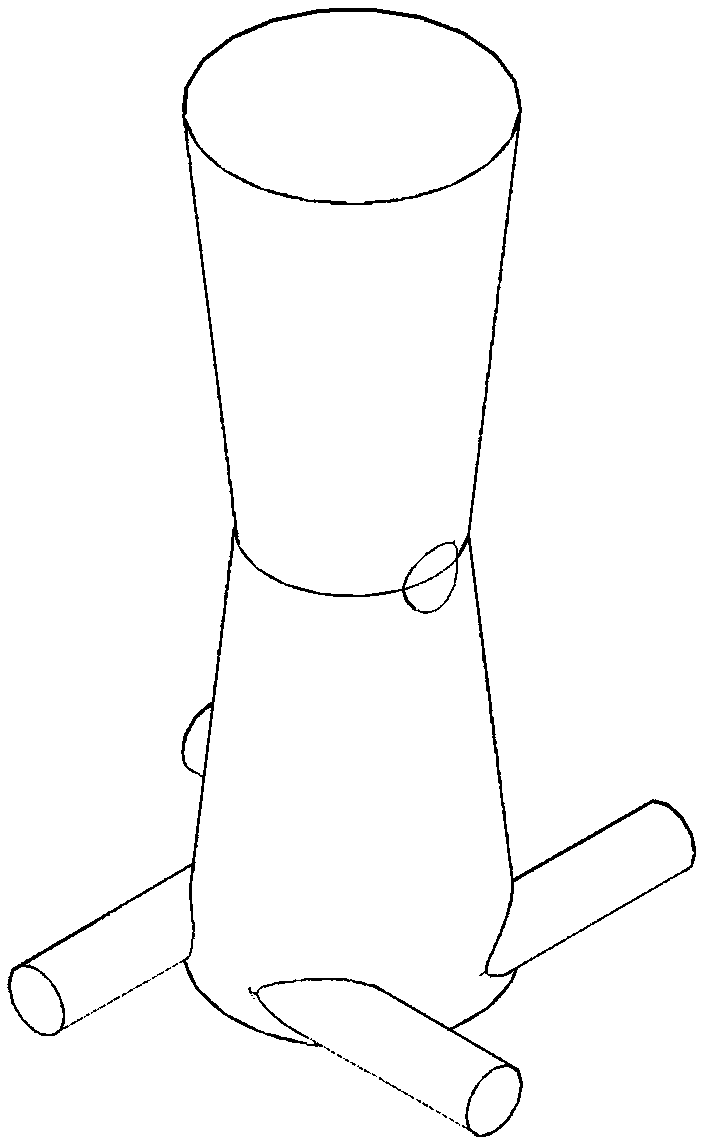

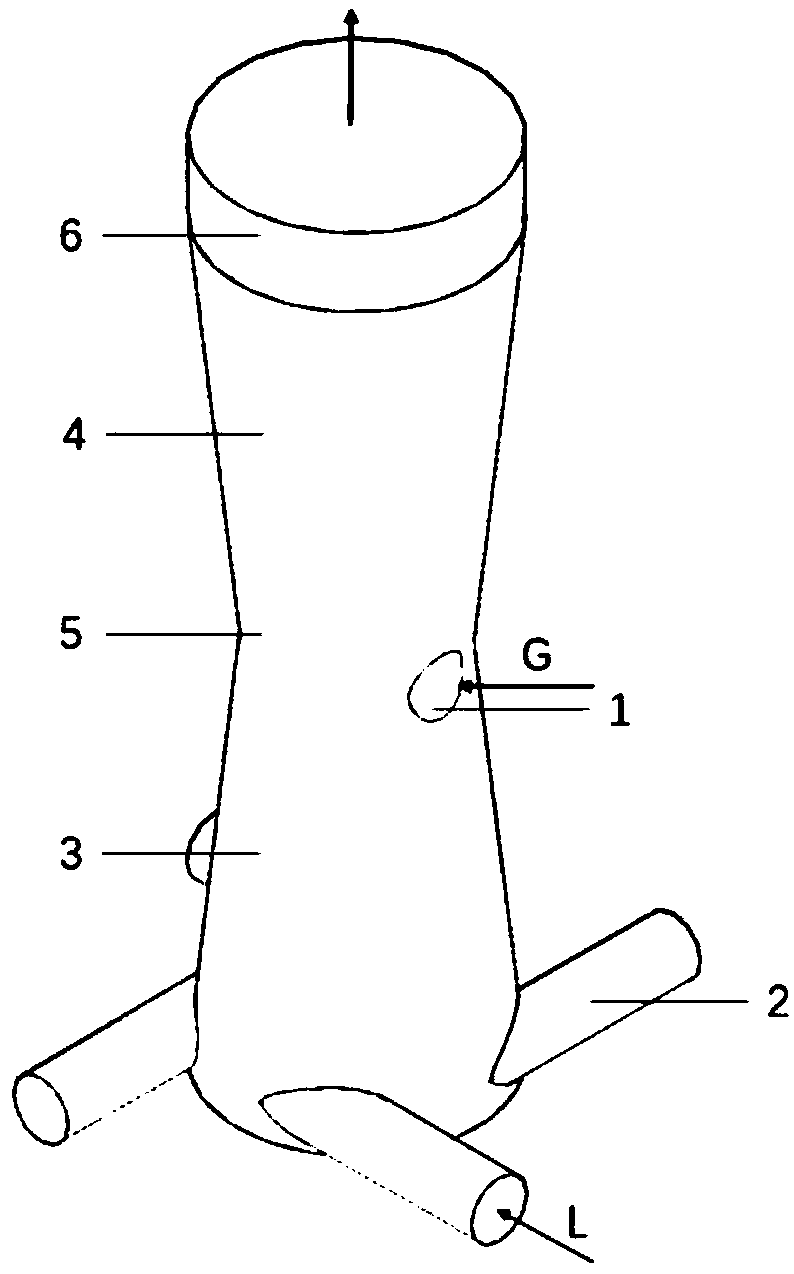

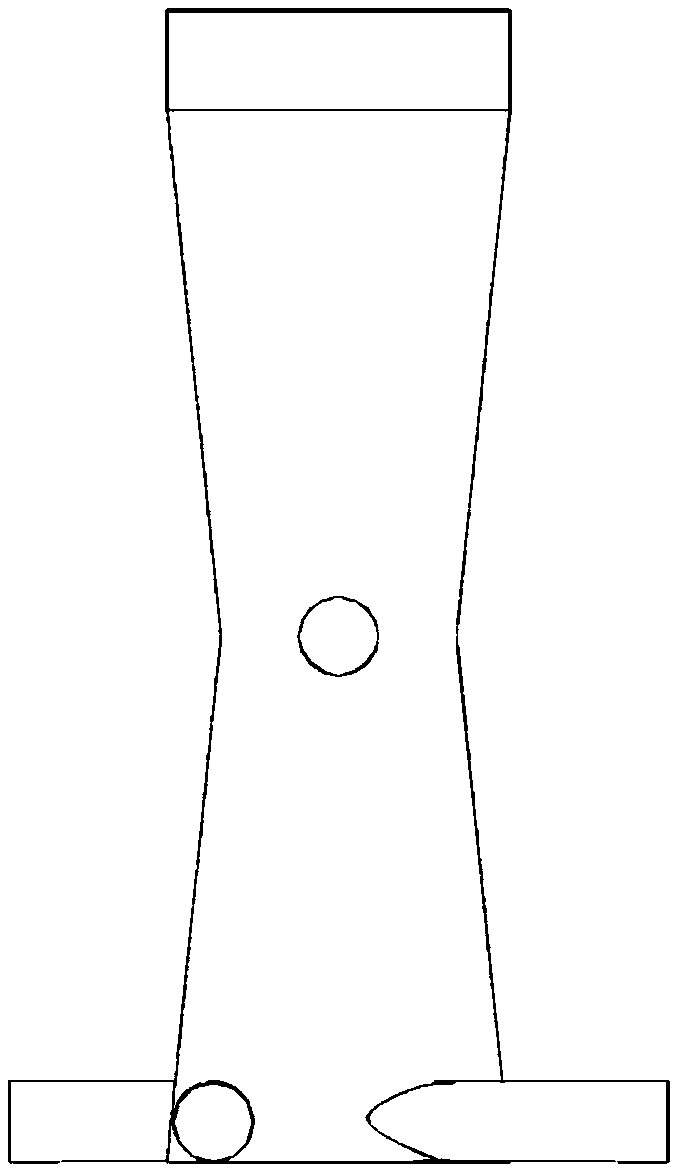

[0036] use as figure 2 The microbubble generator shown includes an air inlet 1 , a liquid inlet pipe 2 , a venturi structure tapering section 3 , an expander pipe 4 , and a throat pipe 5 . The total length of the microbubble generator is 95mm, of which the bottom of the tapering section is closed, the length of the tapering section and the expanding section are both 40mm, the length of the throat is 0mm, and the length of the developing section is 15mm. The diameter of the outlet of the diverging section is equal to the diameter of the bottom of the tapering section, both of which are 26mm. A circular air inlet with a diameter of 6mm, four tangential liquid inlet pipes with a diameter of 6mm and a length of 25mm.

[0037] Taking the air-water system as an example, a high-speed camera is used to measure the size and distribution of the bubbles generated by the microbubble generator. Air velocity at the air inlet u g =0.24m / s, the liquid velocity at the throat increases from t...

Embodiment 3

[0039] The only difference from Example 1 is that the gas velocity u at the air inlet g =0.36m / s, use a high-speed camera to shoot the bubbles generated by the microbubble generator, when the liquid velocity at the throat u l =1.60m / s, microbubble fraction η=64%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com