Surface treatment process of dental implant and application thereof

A dental implant and surface treatment technology, applied in the surface treatment process and application field of dental implants, can solve the problems of no multi-level pore structure, uneven pore structure, unfavorable osseointegration, etc., achieve good interaction, promote bone Combined, highly bioactive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

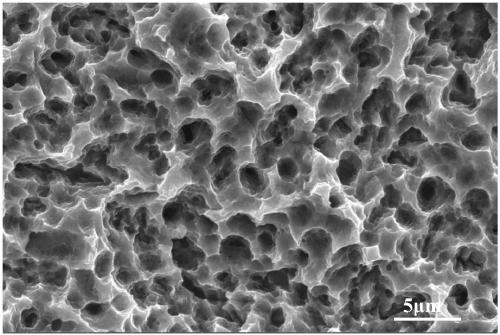

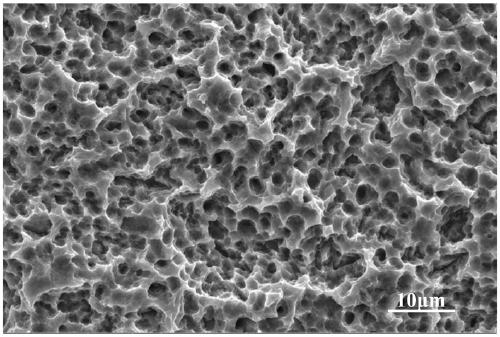

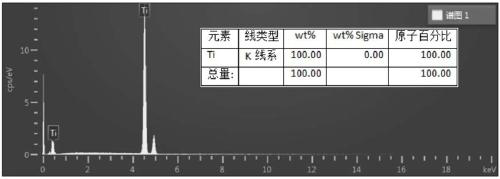

Image

Examples

Embodiment 1

[0042] This embodiment provides a surface treatment process for dental implants, including:

[0043] The surface of the implant was blasted with rutile sand with a mesh number of 35. The sandblasting process is as follows: the angle between the spray gun and the implant is 45°, the distance between the gun nozzle and the implant is 8mm, and the sandblasting time for each implant is 15s.

[0044] After sandblasting, the implants are cleaned and put into acid solution for acid etching. The acid solution includes sulfuric acid, hydrochloric acid and water in a volume ratio of 1:1:2. The acid etching time is 50min, and the acid etching temperature is 65°C. After the acid etching was completed, the implants were ultrasonically cleaned twice in absolute ethanol and deionized water, each time for 10 min.

[0045] The cleaned implant was heated and soaked in NaOH solution with a concentration of 5 mol / L for 24 hours, and the soaking temperature was 60°C. After soaking, cleaning is...

Embodiment 2

[0047] This embodiment provides a surface treatment process for dental implants, including:

[0048] The surface of the implant was blasted with rutile sand with a mesh number of 35. The sandblasting process is as follows: the angle between the spray gun and the implant is 45°, the distance between the gun nozzle and the implant is 8mm, and the sandblasting time for each implant is 15s.

[0049] After sandblasting, the implants are cleaned and put into acid solution for acid etching. The acid solution includes HF, hydrochloric acid and water in a volume ratio of 1:1:2. The acid etching time is 40min, and the acid etching temperature is 55°C. After the acid etching was completed, the implants were ultrasonically cleaned twice in absolute ethanol and deionized water, each time for 10 min.

[0050] The cleaned implant was heated and soaked in NaOH solution with a concentration of 5 mol / L for 24 hours, and the soaking temperature was 60°C. After soaking, cleaning is carried ou...

Embodiment 3

[0052] This embodiment provides a surface treatment process for dental implants. The difference from Embodiment 1 is that the mesh number of the rutile sand is 10 mesh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com