Fireproof rubber shoes and its production process

A production process and technology for rubber shoes, applied in the field of rubber shoes, can solve the problem of high cost, achieve the effect of convenient and rapid disassembly and assembly, prevent lateral deviation, and ensure smooth operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

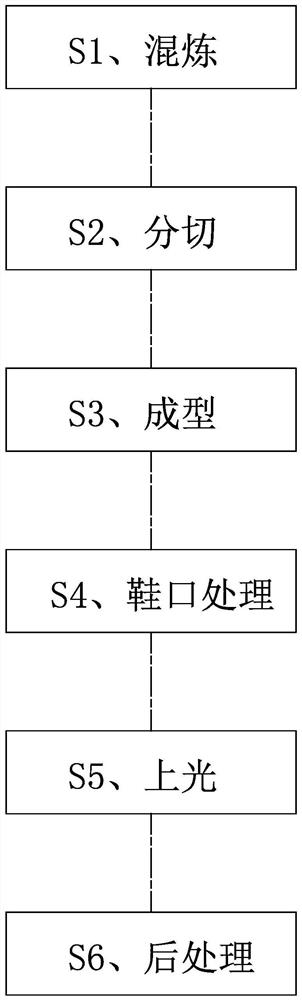

Method used

Image

Examples

Embodiment 1

[0163]Fireproof rubber shoes include the following components and parts by weight: 80 parts of natural rubber, 18 parts of styrene-butadiene rubber, 2 parts of sulfur, 0.2 parts of accelerator, 1.1 parts of DM steel, 5 parts of zinc oxide, 0.5 parts of stearic acid, and anti-aging agent 0.8 parts of MB, 2.0 parts of diethylene glycol, 7 parts of flame retardant, 20 parts of white carbon black and 1.4 parts of resin. . It can meet the requirements of GB / T 35497-2017 rubber shoes-materials for rubber shoes flame retardant performance test method.

Embodiment 2

[0165] Fireproof rubber shoes include the following components and parts by weight: 78 parts of natural rubber, 16 parts of styrene-butadiene rubber, 1 part of sulfur, 0.1 part of accelerator, 1.3 parts of DM steel, 4 parts of zinc oxide, 0.3 parts of stearic acid, anti-aging agent 0.7 parts of MB, 1.8 parts of diethylene glycol, 6 parts of flame retardant, 18 parts of white carbon black and 1.4 parts of resin. It can meet the requirements of GB / T 35497-2017 rubber shoes-materials for rubber shoes flame retardant performance test method.

Embodiment 3

[0167] Fireproof rubber shoes include the following components and parts by weight: 82 parts of natural rubber, 20 parts of styrene-butadiene rubber, 3 parts of sulfur, 0.3 parts of accelerator, 1.0 parts of DM steel, 6 parts of zinc oxide, 0.7 parts of stearic acid, and anti-aging agent 0.9 parts of MB, 2.2 parts of diethylene glycol, 8 parts of flame retardant, 22 parts of white carbon black and 1.4 parts of resin. The synergistic effect of the above components can force the rubber shoes to have very good fire resistance. It can meet the requirements of GB / T 35497-2017 rubber shoes-materials for rubber shoes flame retardant performance test method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com