Miniaturized high-gain circularly polarized antenna based on metamaterial

A circularly polarized antenna, high-gain technology, applied in antennas, antenna components, antenna grounding devices, etc., can solve the problems of increased production costs due to dielectric loss, low overall gain of the antenna, and narrow antenna bandwidth, etc., to achieve small Modern design, good application prospects, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

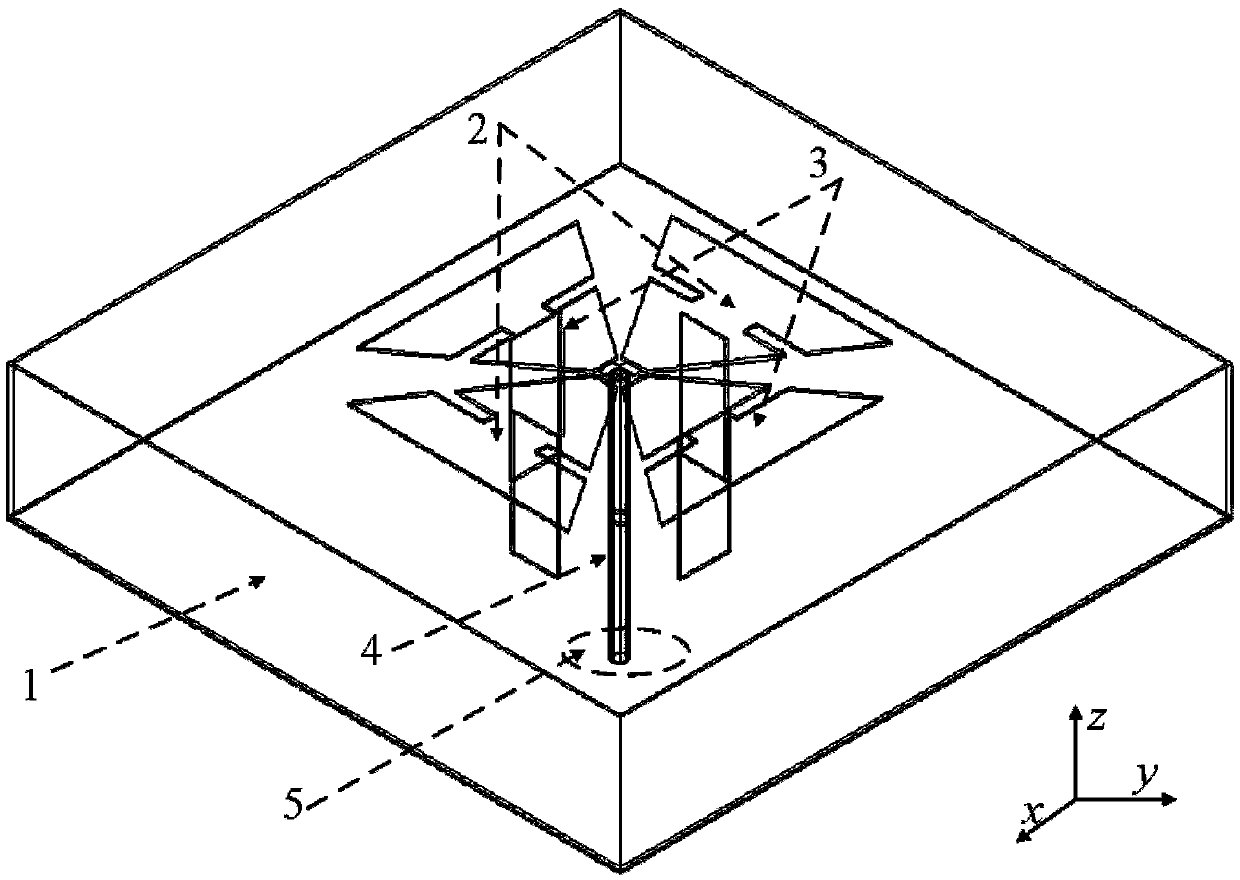

[0031] Such as Figure 1-Figure 5 As shown, a metamaterial-based miniaturized high-gain circularly polarized antenna includes a feed connection port, and the feed connection port is an SMA connected with a 50-ohm semi-rigid coaxial line.

[0032] It also includes a metal floor 1, a feeding coaxial line 4 arranged on the metal floor 1, and a butterfly dipole structure connected to the feeding coaxial line 4;

[0033] The butterfly dipole structure includes a pair of dipole arms arranged symmetrically with respect to the feed coaxial line 4 , there are two pairs of dipole arms, and the two pairs of dipole arms 2 are placed orthogonally. Both ribs on each dipole arm 2 of the butterfly dipole structure are provided with strip-shaped grooves. The dipole arm 2 is provided with a thin plate 3 connection slot, and the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com