Manufacturing method for skeleton-free niobium-tri-tin superconducting coil

A technology for superconducting coils and manufacturing methods, applied in coil manufacturing, inductance/transformer/magnet manufacturing, electrical components, etc., capable of solving problems such as deformation of niobium-three-tin superconducting coils and reduction of total current density of niobium-three-tin superconducting coils , to achieve superior electrical insulation performance, excellent thermal stability, and reduce cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

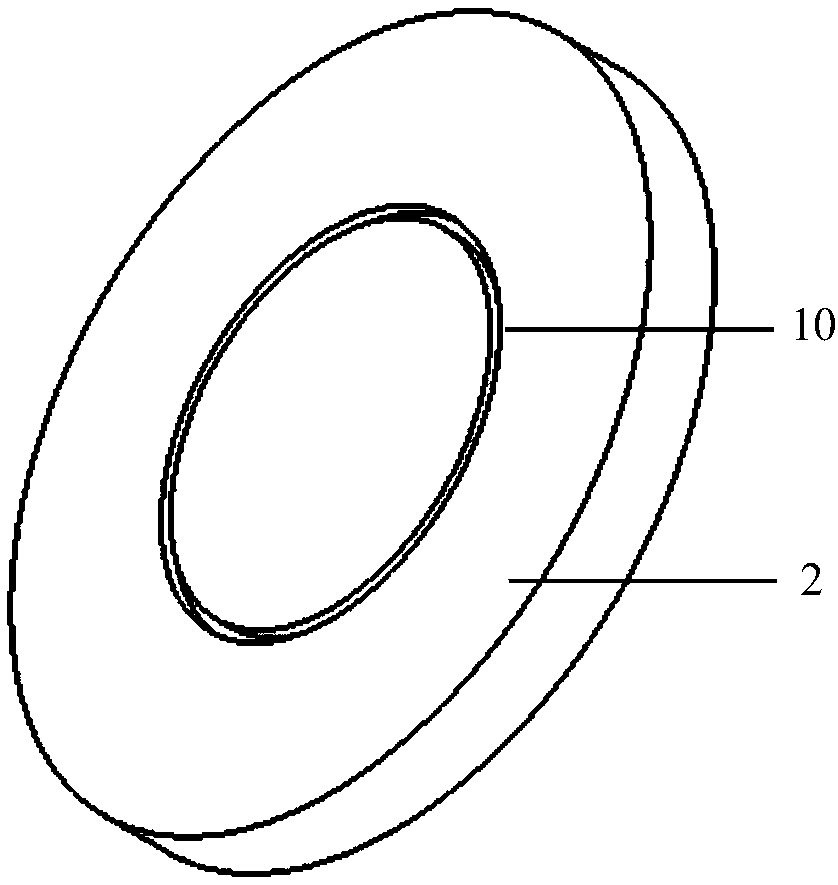

[0035] Connect the cylindrical quartz tube 1 to the two-end plate flange 2, open a circular groove at the junction of the two-end plate flange 2 and the cylindrical quartz tube 1, and insert the cylindrical quartz tube 1 into the circular groove 10 . There is a through hole in the center of the flange 2 of the two end plates, and an M6 screw rod 6 is installed in the through hole. The flanges 2 of the two end plates are tangent to the inner surface of the cylindrical quartz tube 1 and each has a circle of through holes in the circumferential direction, and the number of through holes is three. Three through holes are installed with three M4 screw rods 7 for positioning and clamping, so that the center of the cylindrical quartz tube 1 and the flanges 2 of the end plates are aligned and tightly connected. Install the assembled quartz skeleton on the winding machine. Two layers of glass cloth 3 are wound around the outer surface of the cylindrical quartz tube in half. The wire...

Embodiment 2

[0038] The cylindrical quartz tube 4 is connected with the flanges 2 of the two ends through the annular grooves 10 on the flanges 2 of the two ends. Install a screw rod 6 at the flange center of the two end plates, and fix it with nuts at both ends. There is a through hole in the flange center of the two end plates, and an M20 screw rod 7 is installed in the through hole. The two end plates 2 and the inner surface of the cylindrical quartz tube 1 are respectively provided with a circle of through holes in the circumferential direction, and the number of the through holes is 6. Six M4 screw rods 7 are installed in the through holes for positioning and clamping, so that the center of the cylindrical quartz tube 1 and the flanges 2 of the end plates are aligned and tightly connected. Install the assembled quartz skeleton on the winding machine. Two layers of glass cloth 3 are wound around the outer surface of the cylindrical quartz tube in half. The wires are fed into the wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com