Method for correcting mechanical parameters of perpendicularity of flat pressing head to indentation test material

A material mechanics, perpendicularity measuring instrument technology, used in testing material hardness, using stable tension/pressure testing material strength, analyzing materials, etc., can solve the deviation of material mechanical performance parameters, asymmetric indentation morphology, etc. problem, to achieve the effect of accurate mechanical properties of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

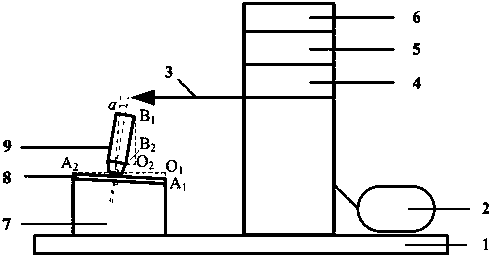

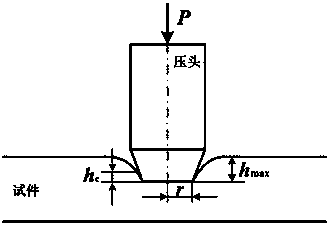

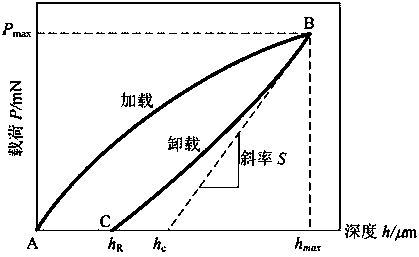

[0042] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0043] see Figure 1 to Figure 6 As shown, the correction method of the verticality of the flat indenter of the present invention to the mechanical parameters of the indentation test material, in the indentation test of the flat indenter, the verticality of the flat indenter relative to the surface of the tested piece is measured by an ultra-precision perpendicularity measuring instrument , through the flat indenter to apply the indentation load to the tested piece to perform the micro-nano indentation test, obtain the load-depth curve of the material indentation test, and calculate the slope of the top of the unloading part of the load-depth curve, according to the elastic-plastic contact theory and The Olive-Pharr method calculates the influence of the verticality of the flat indenter on the contact area of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com