Quartz lamp for high-power high-overload environments

A high-overload, high-power technology, applied in the direction of testing material strength by applying stable shear force, testing material strength by applying stable tension/pressure, measuring devices, etc., can solve transient high temperature-large overload thermal composite test Less heating demand, slow temperature rise rate of heating furnace, large thermal inertia and other problems, to meet the needs of rapid temperature changes and increase the effect of temperature rise rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

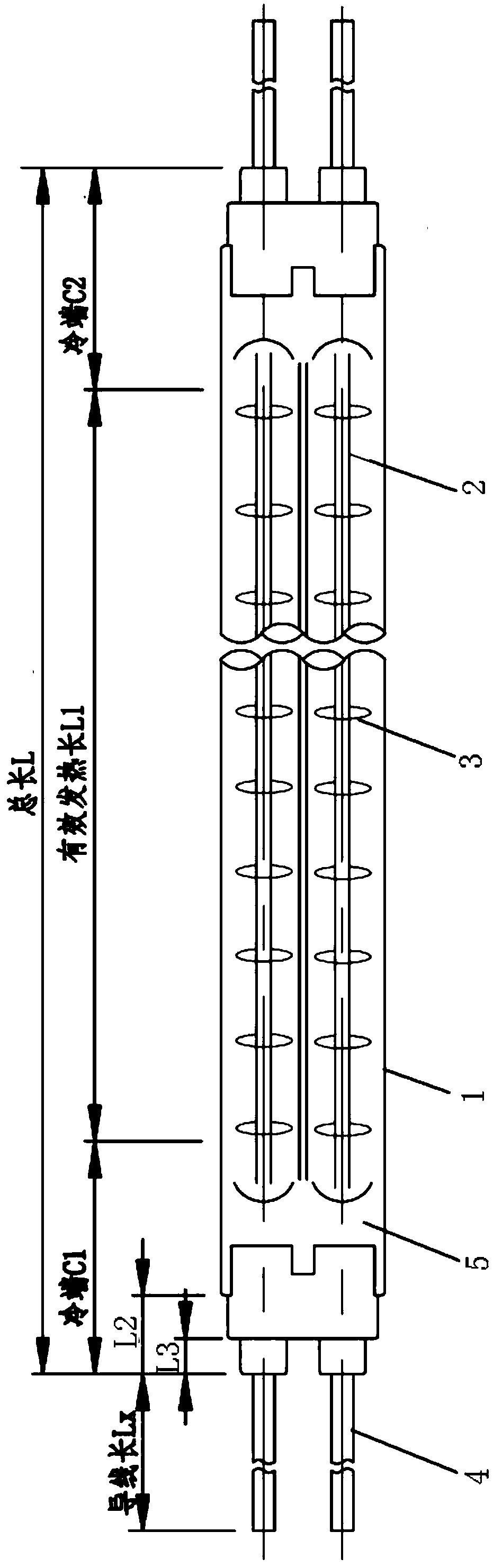

[0030] Example 1, such as figure 1 and figure 2 as shown,

[0031] Quartz lamps for high power and high overload environments, including:

[0032] porous quartz tube 1;

[0033] A plurality of heating wires 2 installed in the porous quartz tube 1;

[0034] respectively connecting the wires 4 at both ends of each heating wire 2;

[0035] A pressure sealing plate 5 for sealing both ends of the porous quartz tube 1;

[0036] A plurality of clamping points 6 are arranged on the inner tube wall of the porous quartz tube 1, and grooves are arranged on the inside of the porous quartz tube 1 at each clamping point 6, and a device for limiting the heating wire 2 is installed in each groove. A holder 3 that moves along the axial direction of the quartz lamp, the holder 3 is sleeved on the heating wire 2 and connected with the heating wire 2 .

[0037] The setting of multiple clamping points 6 and the retainer 3 restricts the movement of the retainer 3 in the tube wall, avoiding t...

Embodiment 2

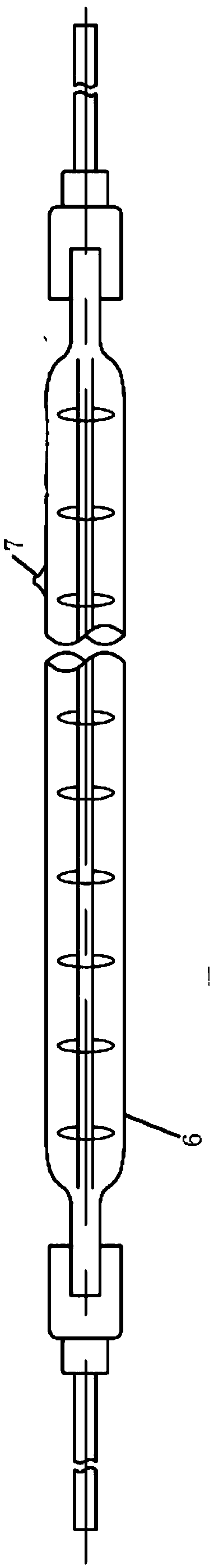

[0038] Example 2, such as figure 2 as shown,

[0039] The difference between this embodiment and embodiment 1 is:

[0040] An exhaust port 7 is also provided on the porous quartz tube 1 .

Embodiment 3

[0041] Example 3, such as figure 2 as shown,

[0042] The difference between this embodiment and embodiment 1 is:

[0043] A plurality of clamping points 6 arranged on the inner wall of the porous quartz tube 1 are evenly spaced. Evenly spaced clamping points 6 are arranged so that the axial force of the heating wire 2 is uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com