Airtightness detection method and device

A technology of air tightness detection and tested parts, which is applied in the direction of liquid tightness measurement by using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, etc., which can solve the problems of long time consumption in the test process and low test efficiency. , to achieve the effect of saving detection time and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present application will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

[0058] This application provides an airtightness detection method, which can be used to detect any parts with sealing requirements. This application takes the battery pack box as an example to describe the airtightness detection method in detail. It should be understood that the tested part is not limited to the case of the battery pack, but may also be other parts, such as air-conditioning cooling pipelines and the like.

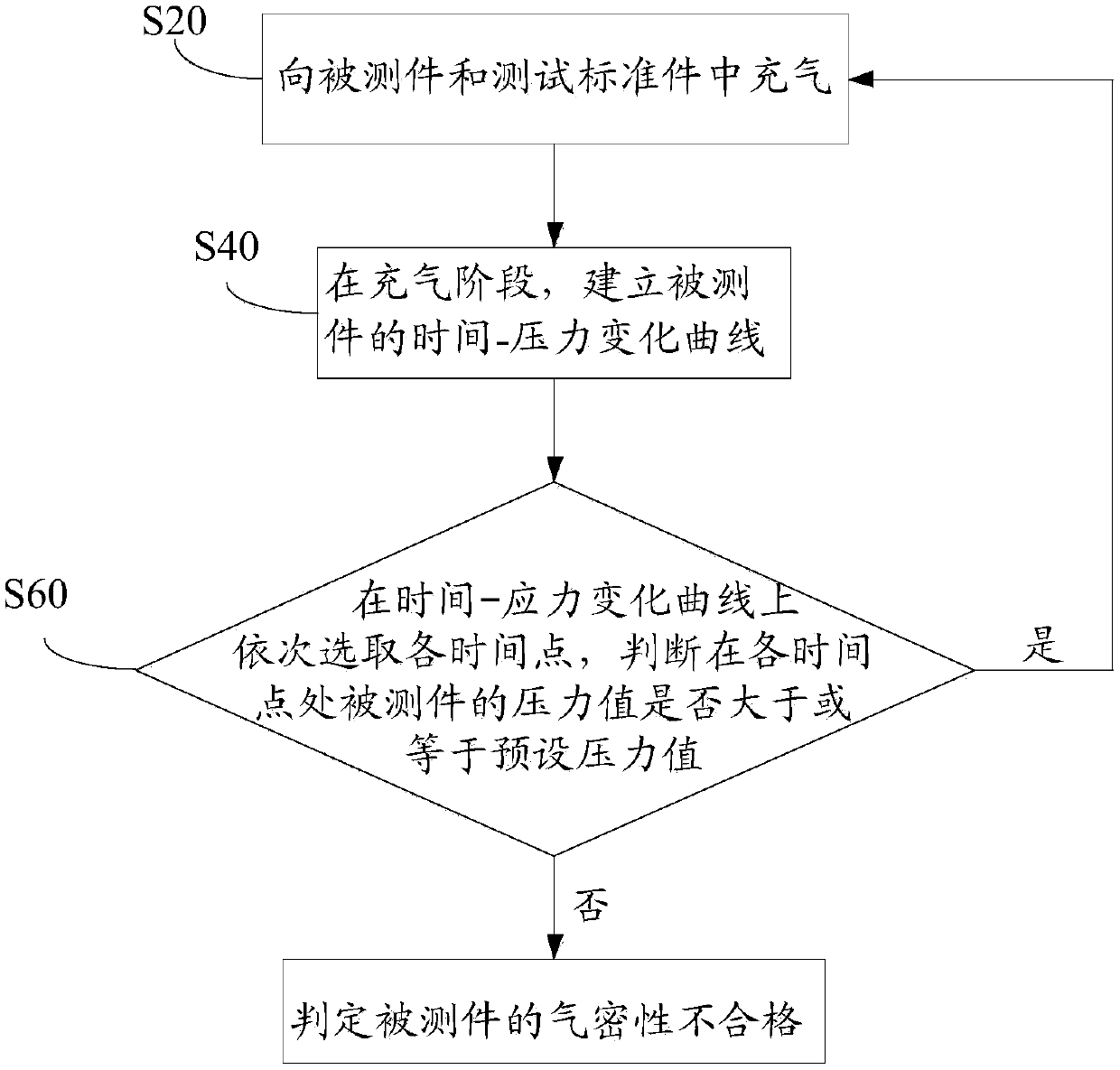

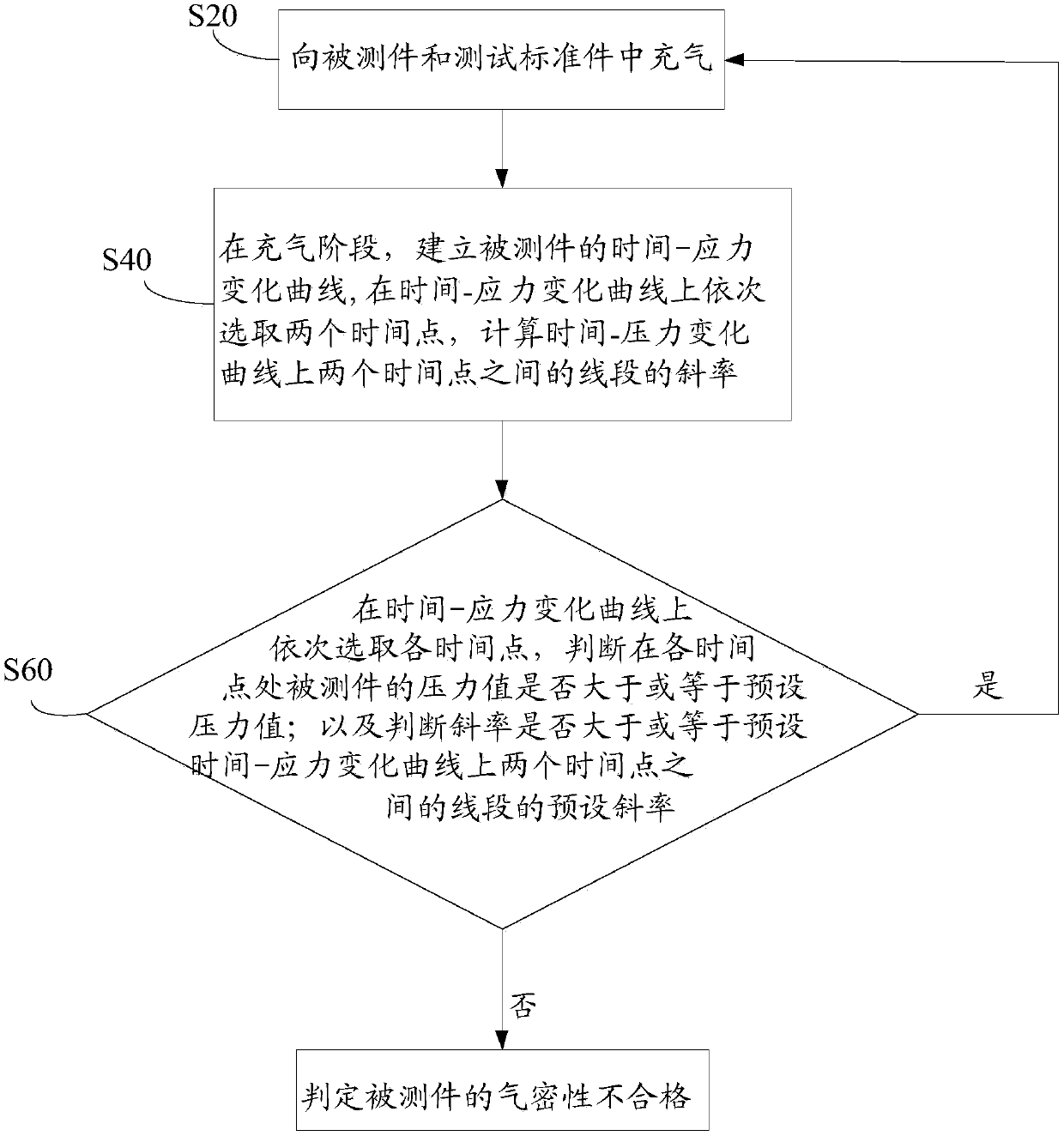

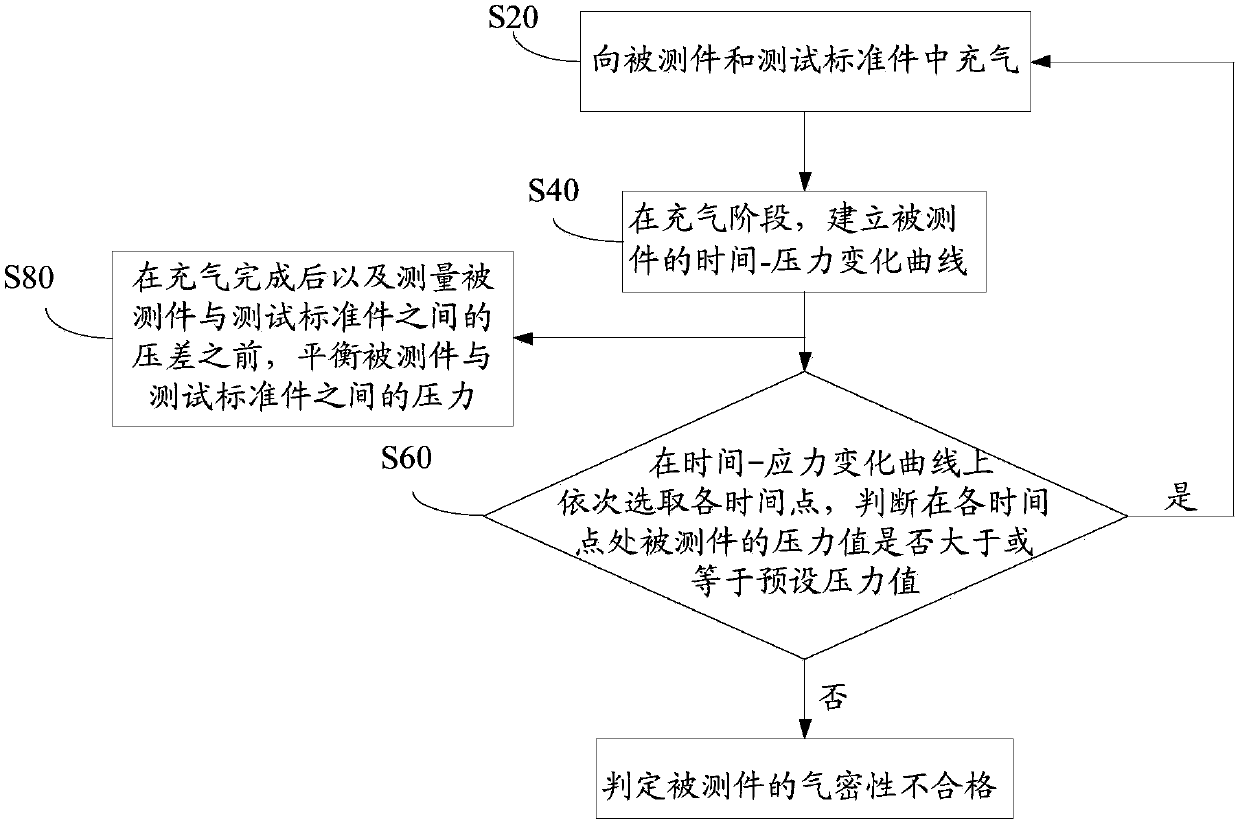

[0059] Such as figure 1 As shown, the detection method includes the following steps:

[0060] Step S20, inflate the DUT and the standard test piece. During the inflation process, the air pressure in the DUT and the standard test piece increases with the inflation time.

[0061] At the same time, during the inflation process, step S40 is executed to establish a time-pressure change curve of the tested ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com