Efficient energy-saving transmission case

A high-efficiency, energy-saving, transmission box technology, applied in transmission boxes, transmission parts, components with teeth, etc., can solve the problems of poor bearing capacity and service life of gears, damage, and large volume of transmission boxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

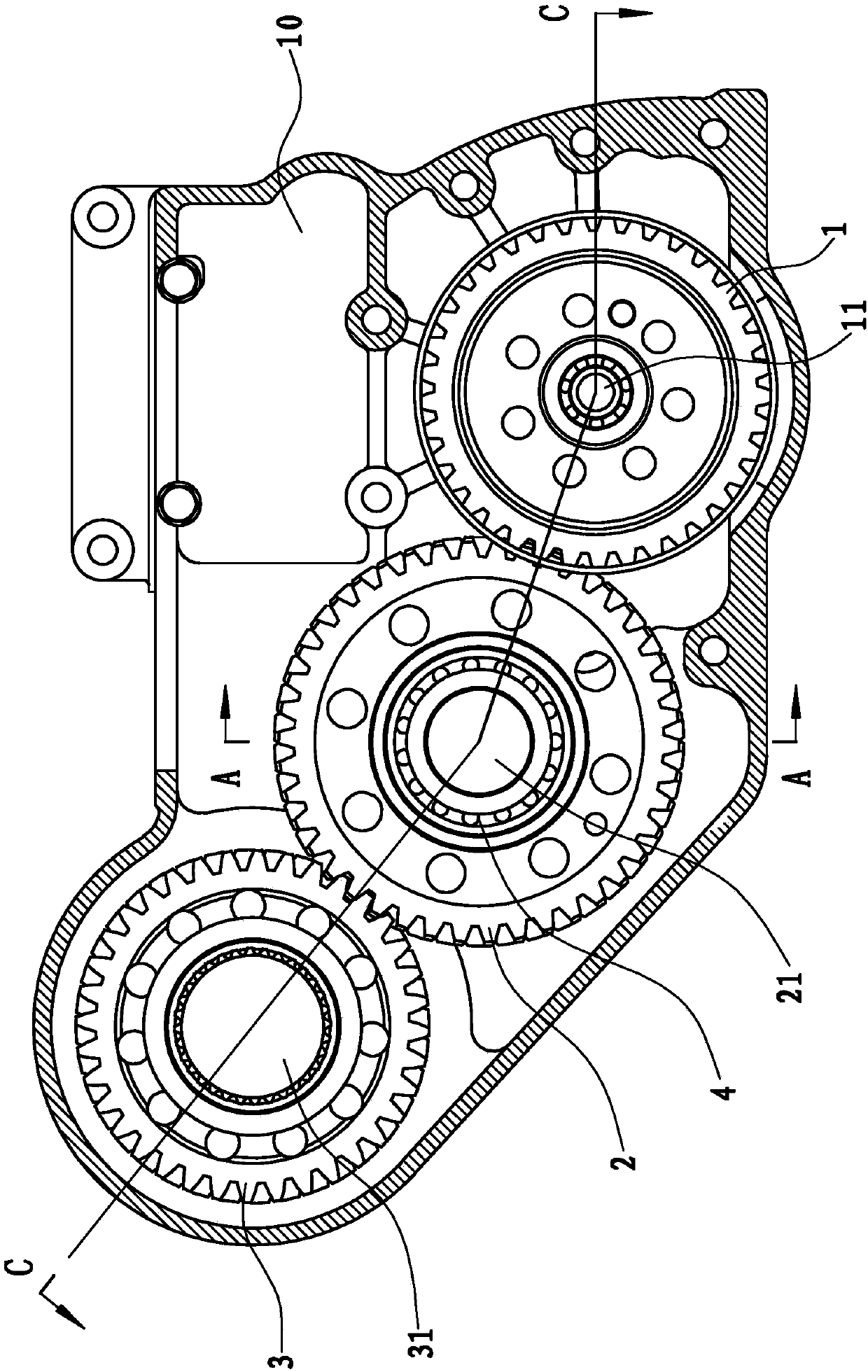

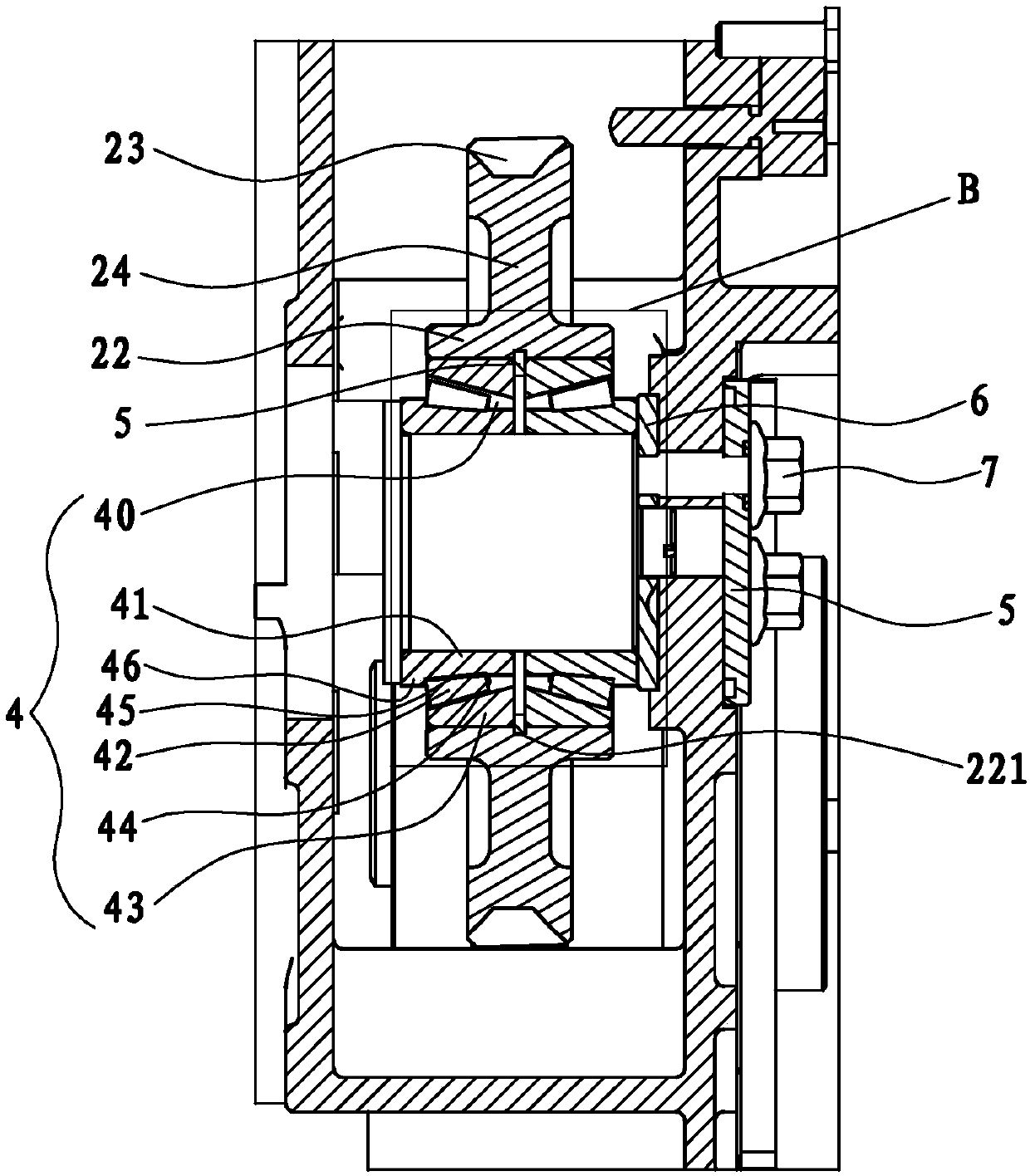

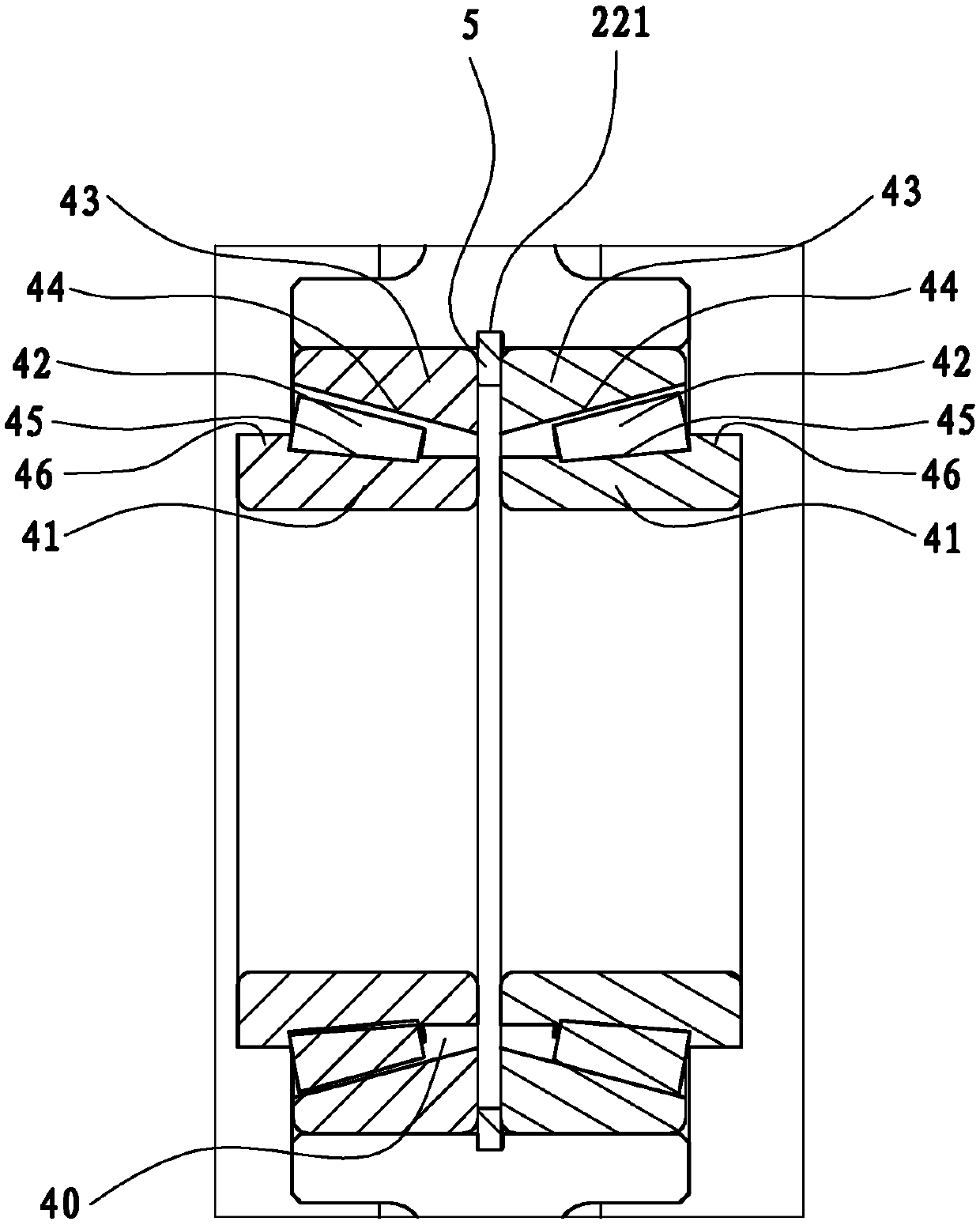

[0034] see Figure 1 to Figure 4 , the present invention discloses a high-efficiency and energy-saving transmission box, which is characterized in that: it includes a casing 10 and a transmission mechanism arranged in the casing 10, and the transmission mechanism has a driving wheel 1, a transition Wheel 2, driven wheel 3; the driving wheel 1 has a driving shaft 11 connected to the engine, the driven wheel 3 has a driven shaft 31 connected to the hydraulic pump, and the transition wheel 2 has a transition wheel shaft 21 and two symmetrically arranged The tapered roller bearing 4 on the transition wheel shaft 21; the tapered roller bearing 4 has a conical annular rolling space 40, and the rolling space 40 has a small conical small end with a small radius and a large conical large end with a large radius, wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com