Pallet Support and Fixtures

A fixing device and tray technology, which is applied in metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of tray rollover, tray shaking, etc., improve heating efficiency, reduce contact area, and weaken heat conduction The effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

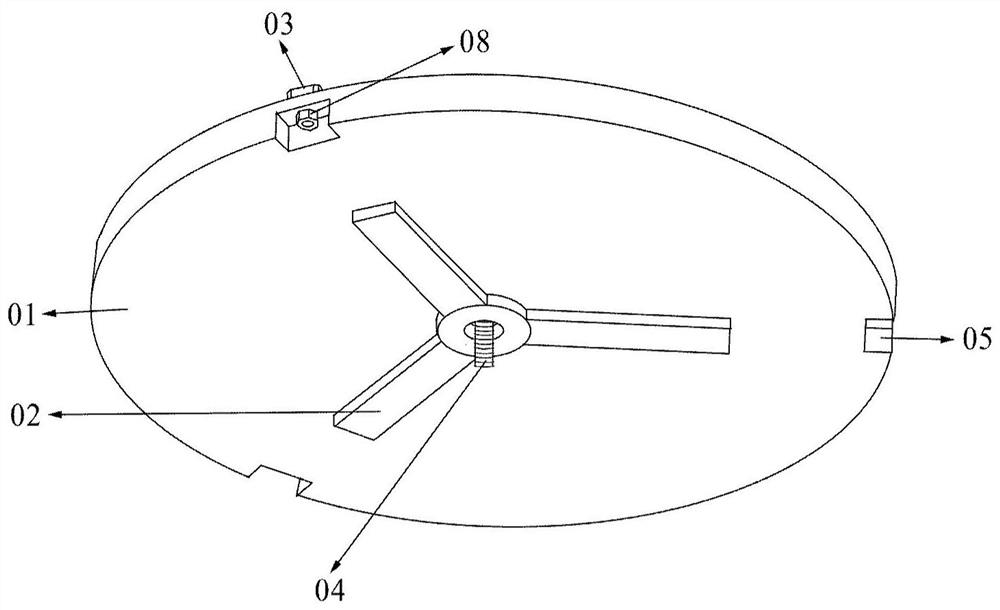

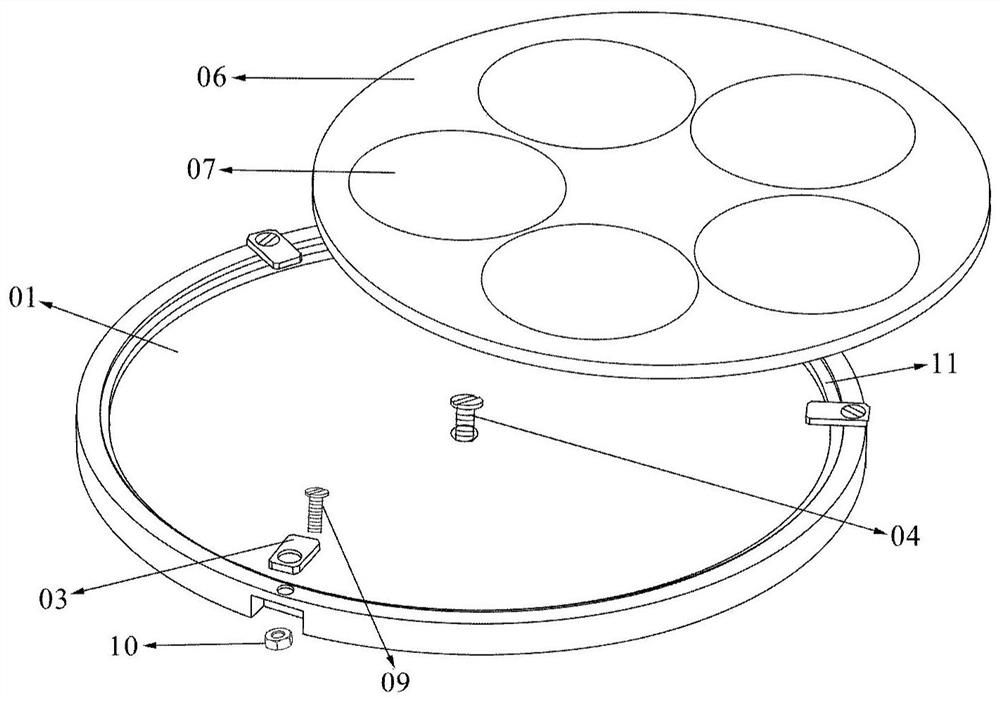

[0033] The disclosure provides a tray supporting and fixing device, which is used to fix the tray on the rotating shaft of the thin film material growth equipment and rotate with the rotating shaft at low or high speed stably, which solves the problem of shaking or shaking of the tray that may be caused by electromagnetic force in induction heating. The problem of rollover can be avoided, and at the same time, it can also reduce the radiation heat loss to the surrounding space after the tray is heated up, and further improve the heating efficiency.

[0034] In order to make the purpose, technical solutions and advantages of the present disclosure clearer, the present disclosure will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0035] In a first exemplary embodiment of the present disclosure, a pallet support and securing device is provided.

[0036] figure 1 It is a structural schematic diagra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com