Rotary kiln gas base reduction-total oxygen bath smelting ironmaking device

A molten pool smelting and molten pool melting furnace technology, applied in the field of rotary kiln gas-based reduction-full oxygen molten pool smelting ironmaking equipment, can solve the problems of large-scale, low-cost production, high fuel ratio, etc., and achieve fast smelting speed , less pollutant discharge and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

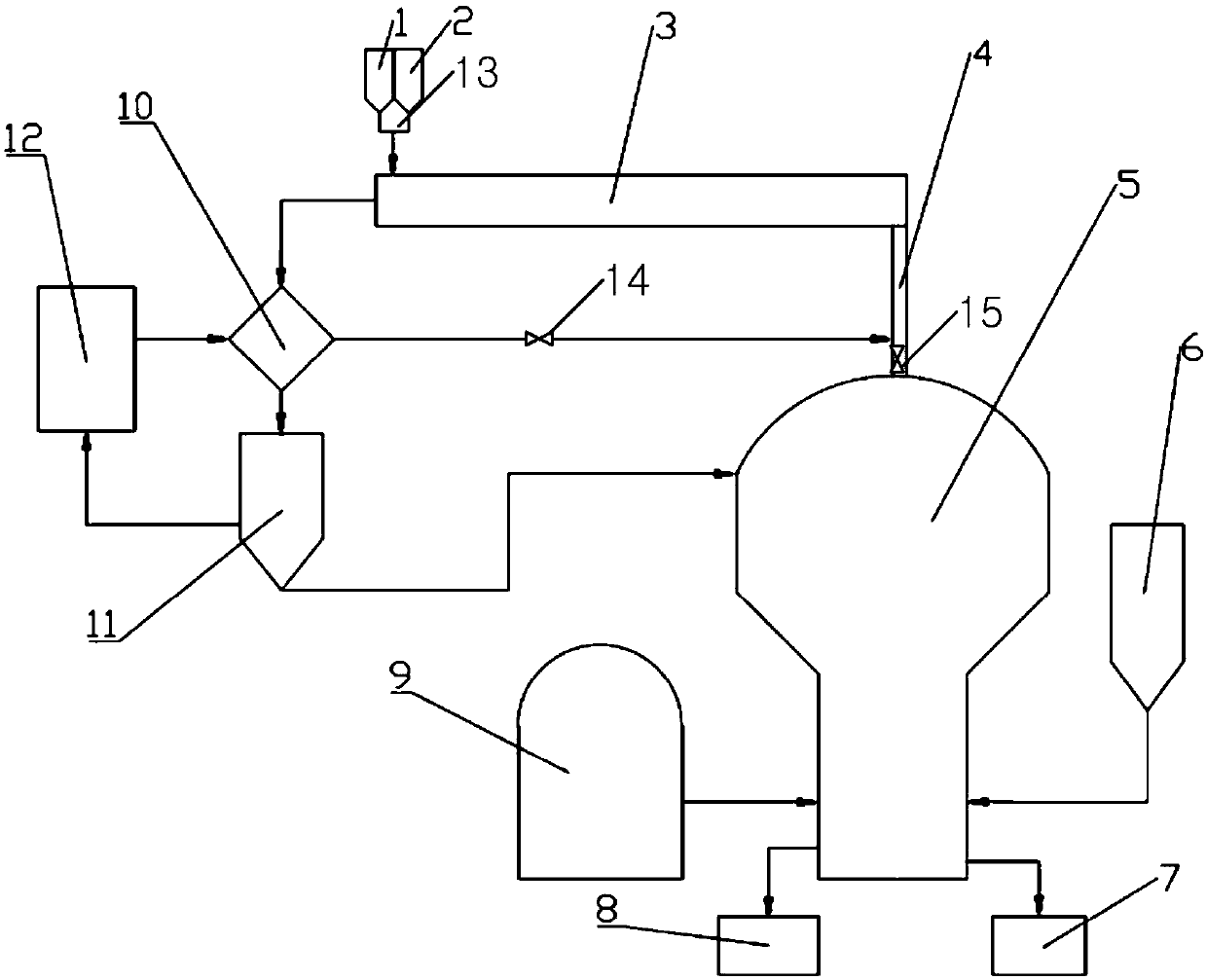

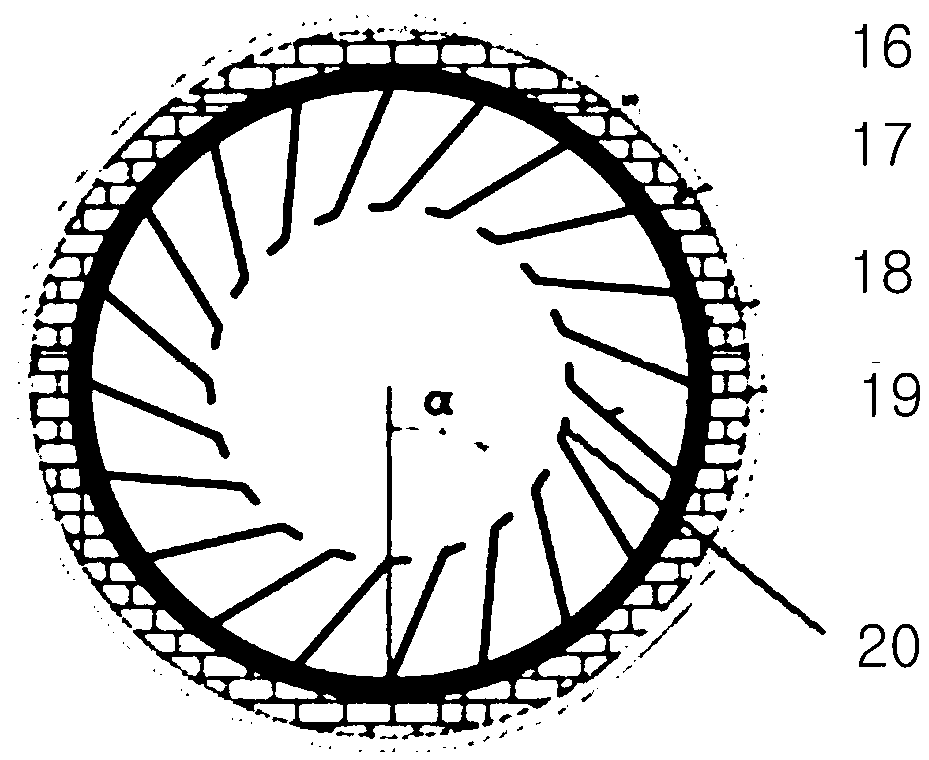

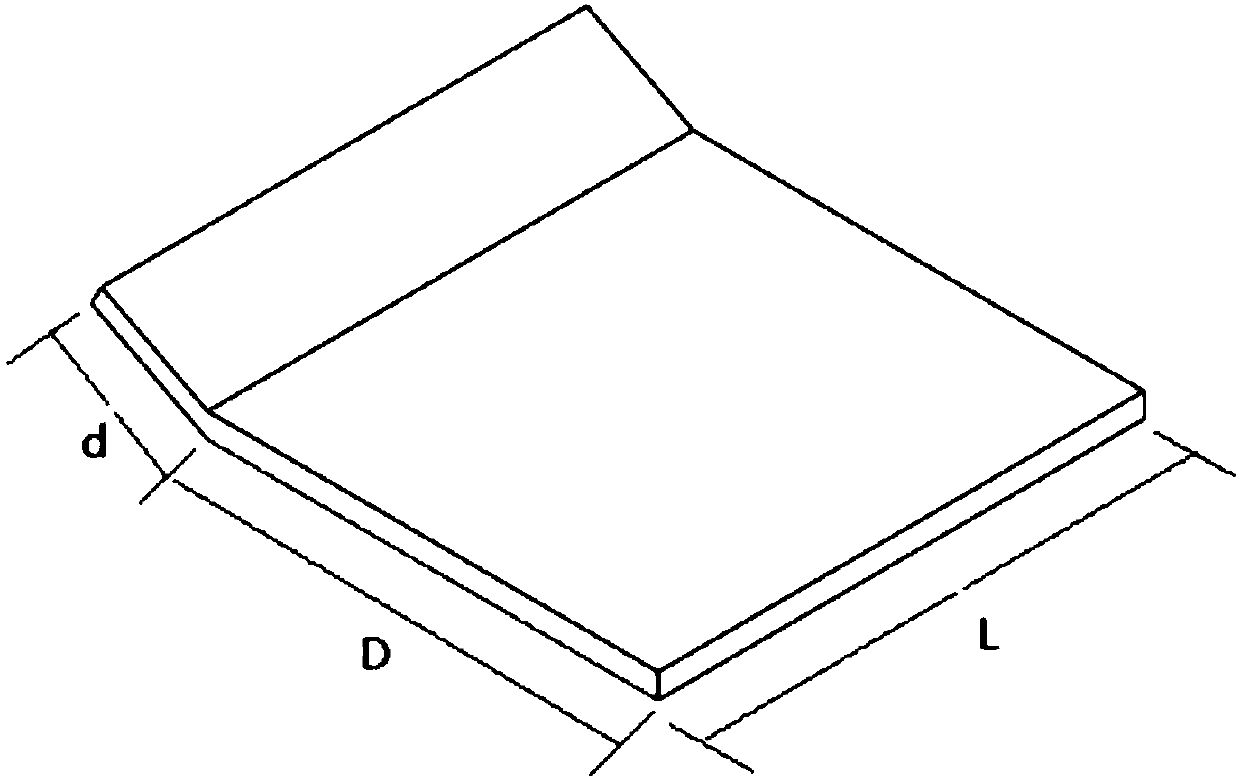

[0034] This embodiment provides a rotary kiln gas-based reduction-full oxygen molten pool smelting ironmaking device, see Figure 1 to Figure 4 , including raw material warehouse, rotary kiln 3, full oxygen melting pool melting furnace 5, pulverized coal warehouse 6, oxygen tank 9, slag tank 8 and molten iron tank 7. Wherein, the raw material warehouse, the rotary kiln 3 and the full-oxygen melting pool melting furnace 5 are connected successively, the slag iron outlet of the full-oxygen melting pool melting furnace 5 is connected with the slag tank 8 and the molten iron tank 7 respectively, and the outlet of the pulverized coal bunker 6 and the The gas outlets of the oxygen tank 9 are all communicated with the air inlet of the full-oxygen melting pool smelting furnace 5; The gas outlet of molten pool smelting furnace 5 communicates with the air inlet of rotary kiln 3 kiln heads.

[0035]During implementation, the smelting raw materials are added to the rotary kiln 3 through ...

Embodiment 2

[0065] This embodiment provides a rotary kiln gas-based reduction-full oxygen molten pool smelting ironmaking method, including the following steps:

[0066] Step 1: The iron ore powder and flux are fed into the rotary kiln through the belt according to the designed ratio, and the iron ore powder is heated and directly reduced by air-based in the rotary kiln to generate kiln tail gas and obtain the pre-reduced charge;

[0067] Step 2: The pre-reduced charge is directly hot-charged into the full-oxygen molten pool melting furnace, and the mixed gas of coal powder and oxygen is injected into the full-oxygen molten pool melting furnace, and the pre-reduced charge is vigorously stirred for final reduction and separation of slag and iron. Generate smelting furnace gas to obtain slag and molten iron. When the molten iron has accumulated to a certain amount, open the iron hole to release molten iron and slag; mix the generated kiln tail gas with smelting furnace gas to obtain mixed ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com