3D printing material and preparation method thereof

A 3D printing and raw material technology, applied in the direction of additive processing, etc., can solve the problems of difficult degradation and poor functionality, and achieve the effect of high tensile strength and high impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of described 3D printing material, it comprises the following steps:

[0021] (1) Preparation of primary mixture: toluene, carbon disulfide, nano-titanium dioxide, γ-aminopropyltriethoxysilane, 2-chlorophenyloxirane, ethyl 2-chloromethylbenzoate, 1, 4-dichloro-2-butene and graphene oxide are heated and mixed to obtain an initial mixture;

[0022] (2) Ball milling: Add the initial mixture obtained in step (1) and 1-ethyl-3-methylimidazolium tetrafluoroborate into a ball mill, and use the ball mill to mill at a speed of 500-800r / min for 1-2h , to get the ball milled product;

[0023] (3) Preparation of blend A: mix the ball-milled product obtained in step (2) with epoxy acrylate, 2,6-di-tert-butyl-4-methylphenol, 2-(2'-hydroxyl-3' , 5'-di-tert-phenyl)-5-chlorinated benzotriazole heated and stirred to obtain blend A;

[0024] (4) Preparation of blend B: Blend A, nano-calcium carbonate powder, and ferrocene derivatives of step (3) gained are mixed ...

Embodiment 1

[0034]A 3D printing material, which includes the following raw materials in parts by weight: 200 parts of toluene, 400 parts of carbon disulfide, 7 parts of nano-titanium dioxide, 10 parts of γ-aminopropyltriethoxysilane, 2-chlorophenyl ring 50 parts of oxyethane, 90 parts of ethyl 2-chloromethylbenzoate, 25 parts of 1,4-dichloro-2-butene, 80 parts of graphene oxide, 1-ethyl-3-methylimidazolium tetrafluoro 10 parts of borate, 40 parts of epoxy acrylate, 2 parts of 2,6-di-tert-butyl-4-methylphenol, 2-(2'-hydroxy-3',5'-di-tert-phenyl)- 6 parts of 5-chlorinated benzotriazole, 7 parts of nano calcium carbonate powder, 35 parts of ferrocene derivatives, 3 parts of benzoyl peroxide;

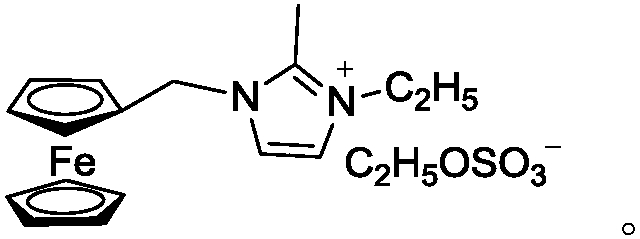

[0035] Wherein, the structural formula of the ferrocene derivative is:

[0036]

[0037] The average particle diameter of the nano-calcium carbonate powder is 100 nanometers.

[0038] The average particle diameter of the nano-titanium dioxide is 80 nanometers.

[0039] The preparation method of t...

Embodiment 2

[0051] A 3D printing material, which includes the following raw materials in parts by weight: 280 parts of toluene, 300 parts of carbon disulfide, 9 parts of nano-titanium dioxide, 5 parts of γ-aminopropyltriethoxysilane, 2-chlorophenyl ring 60 parts of oxyethane, 80 parts of ethyl 2-chloromethylbenzoate, 35 parts of 1,4-dichloro-2-butene, 70 parts of graphene oxide, 1-ethyl-3-methylimidazolium tetrafluoro 15 parts of borate, 30 parts of epoxy acrylate, 5 parts of 2,6-di-tert-butyl-4-methylphenol, 2-(2'-hydroxy-3',5'-di-tert-phenyl)- 5 parts of 5-chlorinated benzotriazole, 9 parts of nano calcium carbonate powder, 25 parts of ferrocene derivatives, 8 parts of benzoyl peroxide;

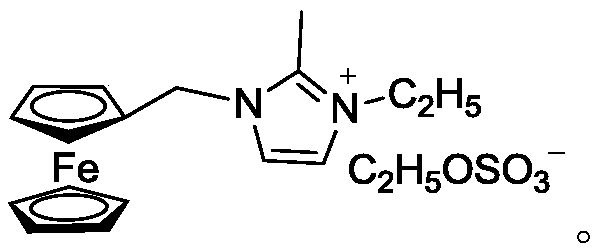

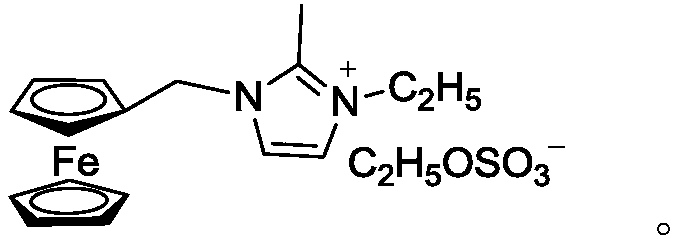

[0052] Wherein, the structural formula of the ferrocene derivative is:

[0053]

[0054] The average particle size of the nano-calcium carbonate powder is 500 nanometers.

[0055] The average particle diameter of the nano-titanium dioxide is 20 nanometers.

[0056] The preparation method of descr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com