A kind of metavanadate fluorescent ceramic bulk material and preparation method thereof

A technology of fluorescent ceramics and metavanadate, which is applied in the direction of luminescent materials, chemical instruments and methods, sustainable buildings, etc. It can solve the problems of poor uniformity, inability to prepare sintered ceramics, and difficulty in obtaining pure equivalence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

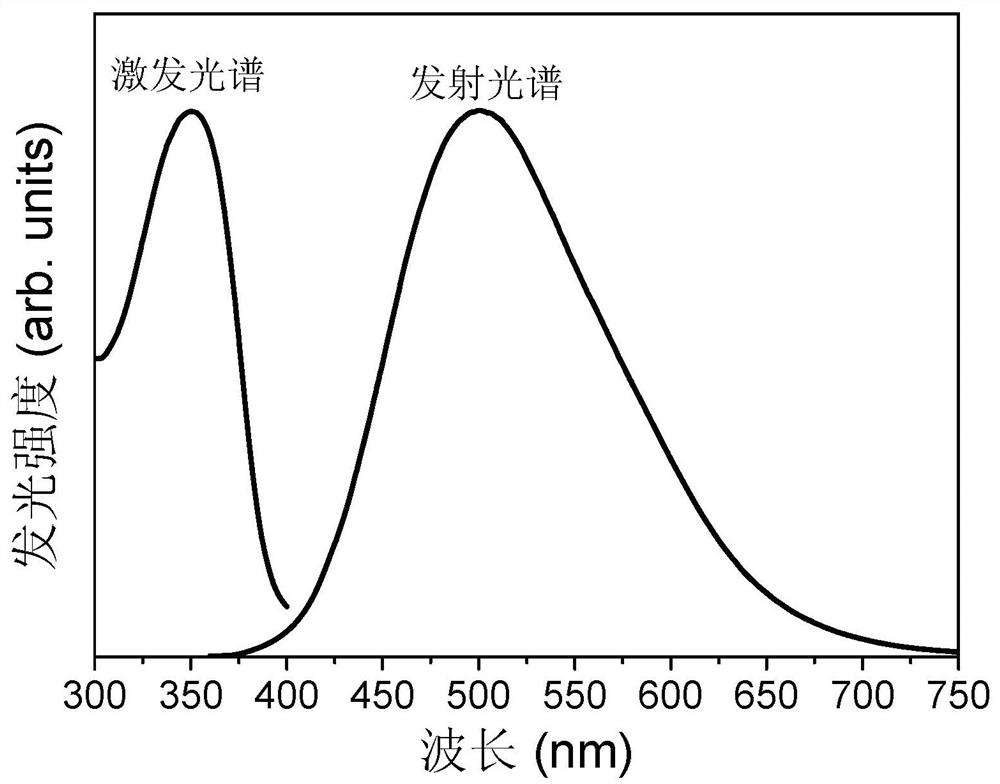

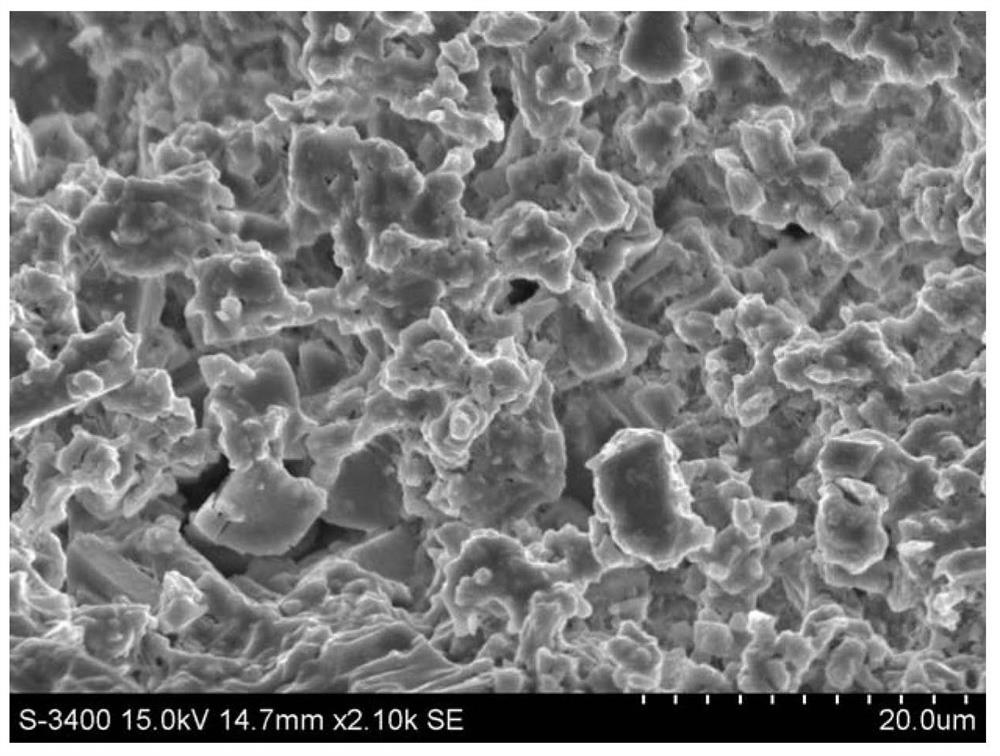

[0034] The invention relates to a metavanadate fluorescent ceramic and a preparation method thereof. The ceramics use alkali metal carbonate and vanadium-containing compounds as raw materials, grind a certain proportion of the raw material mixture and / or the metavanadate powder obtained by calcining the raw material mixture, and then preform and press to obtain a green body , sintering at a certain temperature to obtain bulk metavanadate sintered ceramics; or directly hot-press sintering the raw material mixture and / or metavanadate powder to obtain bulk metavanadate sintered ceramics. The obtained sintered ceramics have obvious white light fluorescence characteristics. The ceramics prepared by the method of the invention have high purity, simple method, high yield, and are suitable for large-scale production; the product has high quantum efficiency and light emission bandwidth, and is suitable for magnetron sputtering targets or white light diodes and other light emitting comp...

Embodiment 1

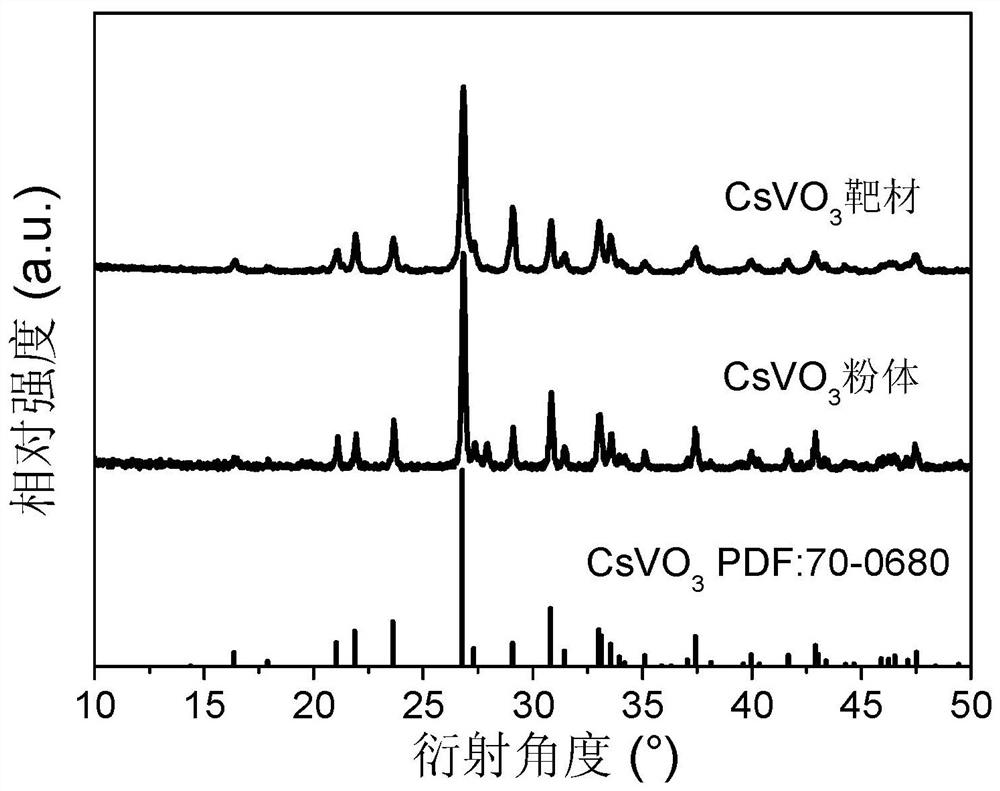

[0054] Step A) Weigh 20.2g cesium carbonate and 9.8g vanadium pentoxide. Dissolve cesium carbonate in 200ml of methanol, ultrasonicate for 30 minutes to promote its dissolution, mix the obtained transparent cesium carbonate methanol solution with vanadium pentoxide, grind and stir until the methanol is completely volatilized. The raw materials were placed in a heating furnace, heated to 400°C, and reacted for 24 hours to obtain white cesium metavanadate powder, which was analyzed by XRD to determine the phase. The results are shown in figure 1 .

[0055] Step B) The powder is transferred to a circular mold with a diameter of 55 mm and dry-pressed under a pressure of 1.5 MPa. The obtained block is put into a balloon and vacuumed, and then the balloon is put into an isostatic press, pressurized at 260 MPa, and kept under pressure for 15 minutes. Get a sintered green body.

[0056] Step C) The green body is wrapped in quartz sand and placed on a corundum plate, and a flat corun...

Embodiment 2

[0063] Step A) Weigh 6.329g of rubidium carbonate and 4.466g of vanadium pentoxide. Dissolve rubidium carbonate in 200ml of methanol, and ultrasonicate for 20-30 minutes to promote its dissolution. Mix rubidium carbonate methanol solution with vanadium pentoxide, grind and stir until the methanol is completely volatilized. The raw materials were placed in a heating furnace, and the temperature was raised to 450°C, and reacted for 24 hours to obtain white rubidium metavanadate powder.

[0064] Step B) The powder is transferred to a circular mold with a diameter of 55mm and dry-pressed under a pressure of 3.0MPa. The obtained block is put into a balloon and vacuumed, and then the balloon is put into an isostatic press, pressurized at 280MPa, and kept under pressure for 15 minutes. Get a sintered green body.

[0065]Step C) The green body is wrapped in quartz sand and placed on a corundum plate, and a flat corundum plate is pressed on top, then transferred to a high-temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com