Low-chrome magnesite-chrome brick for glass kiln

A chrome-magnesium-chrome brick and glass kiln technology, applied in the field of refractory materials, can solve problems such as hexavalent chromium pollution of the environment, achieve significant social and economic benefits, alleviate pollution, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

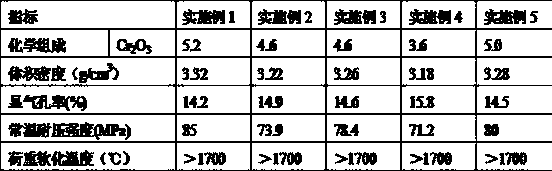

Examples

Embodiment 1

[0022] A low-chromium magnesia-chrome brick, expressed in mass percentage, its raw material composition is: 20% fused magnesia with a particle size of 4-2mm, 12% fused magnesia with a particle size of 2-1mm, and fused magnesia-aluminum spinel with a size of 2-1mm 10% magnesia, 1-0mm magnesia chrome sand 26%, <0.088mm fused magnesia 32%, in addition add binder sulfurous acid pulp waste liquid and magnesium chloride solution (the binder specific gravity is 1.25 ), the raw materials of the above formula are weighed, kneaded, molded, dried, and fired at 1700°C for 8 hours.

Embodiment 2

[0024] The low-chrome magnesia-chrome brick of the present invention is represented by mass percentage, and the raw materials are composed of: 18% fused magnesia with a particle size of 4-2mm, 11% fused magnesia with a particle size of 2-1mm, and fused magnesia-aluminum spinel with a size of 2-1mm 17%, 1-0mm magnesia chrome sand 23%, <0.088mm fused magnesia 31%; in addition, add binder sulfurous acid pulp waste liquid (binder specific gravity 1.35) accounting for 4% of the total mass of all the above-mentioned raw materials, and mix the above The raw materials of the formula are obtained by weighing, kneading, molding, drying, and firing at 1750°C for 7 hours.

Embodiment 3

[0026] The low-chromium magnesia-chrome brick of the present invention is represented by mass percentage, and the raw materials are composed of: 16% of fused magnesia with a particle size of 4-2mm, 10% of fused magnesia with a particle size of 2-1mm, and fused magnesia-aluminum spinel with a size of 2-1mm 16%,; 1-0mm magnesia chrome sand 23%, <0.088mm fused magnesia 35%; in addition, a binder magnesium chloride solution accounting for 4.5% of the total mass of all the above-mentioned raw materials is added (the specific gravity of the binder is 1.30), and the above formula The raw materials are weighed, kneaded, molded, dried, and fired at 1760°C for 5 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com