Foaming agent for foam concrete and preparation method thereof

A foamed concrete and foaming agent technology, applied in the field of building materials, can solve the problems of large influence of environmental temperature, short shelf life of foaming agent, unsatisfactory stability, etc., and achieves strong foam stability and uniformity, storage resistance, improvement The effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

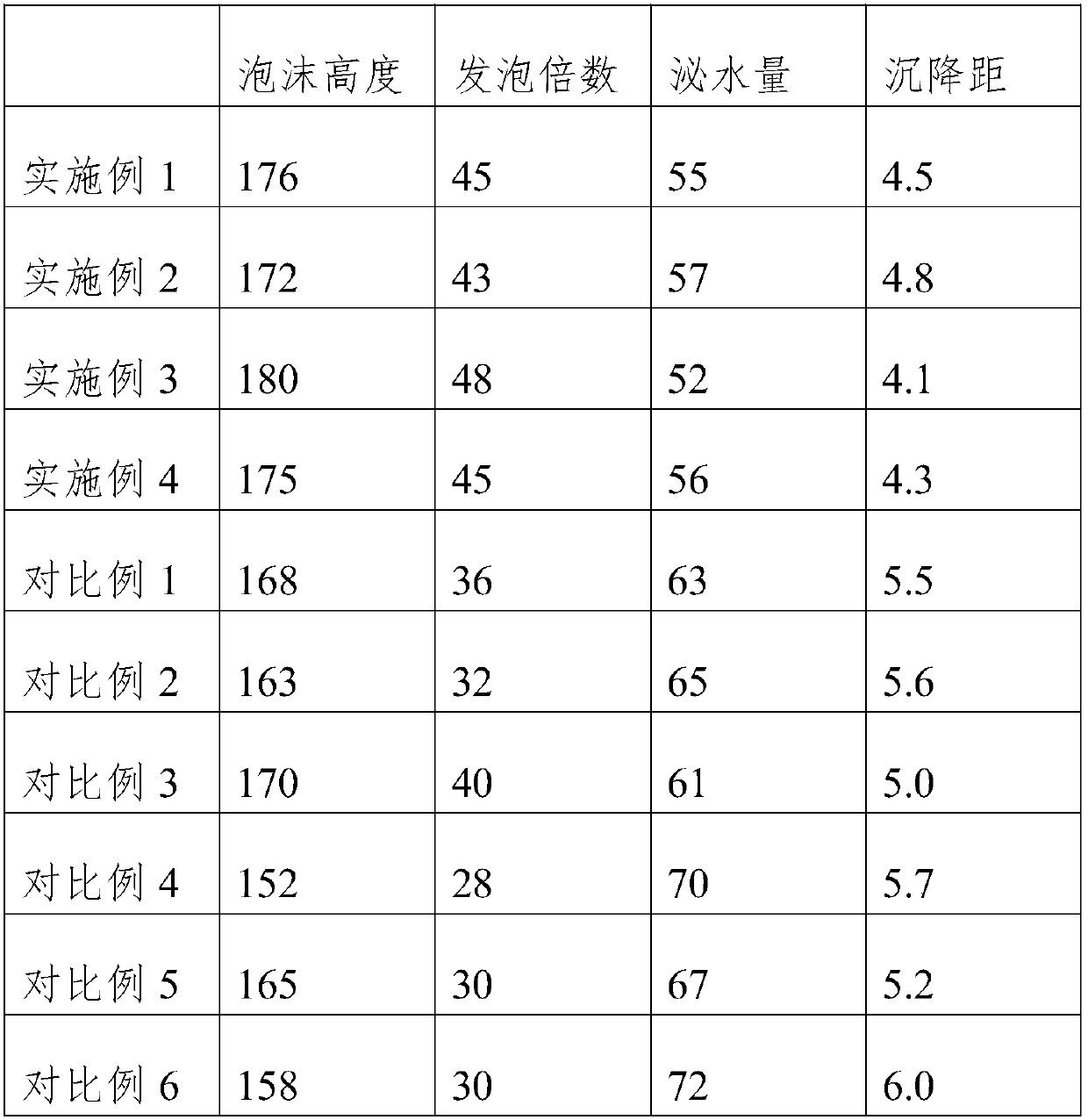

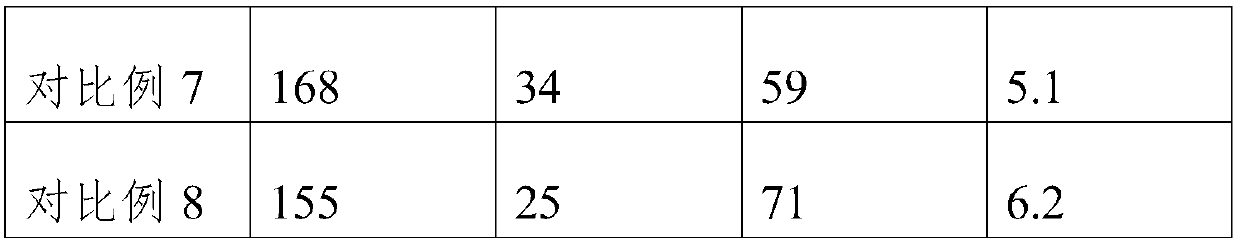

Examples

Embodiment 1

[0027] A foaming agent for foam concrete, consisting of the following raw materials: washing powder 10g, egg white 4g, colchicine 0.3g, pomelo peel fermented product 20g, japonica rice extract 30g, betaine 0.2g, lotus leaf fermented product 16g, Marble powder 0.3g;

[0028] The grapefruit peel fermented product is that grapefruit peel and water are mixed at high speed according to the mass ratio of grapefruit peel: water=1:1.6 to make grapefruit peel pulp, after being treated with a direct current constant strong magnetic field with a magnetic field strength of 3T for 15s, press 1.5 ×10 7 The amount of cfu / mL was inoculated with brewer's yeast and fermented for 5 days at a temperature of 30°C, and then treated with a DC constant-strength magnetic field with a magnetic field strength of 4-5T for 10 seconds, and then pressed 3.2×10 6 The amount of cfu / mL was inoculated with lactic acid bacteria and fermented for 5 days at a temperature of 28°C;

[0029] The lotus leaf fermente...

Embodiment 2

[0038] A foaming agent for foam concrete, consisting of the following raw materials: washing powder 8g, egg white 2g, colchicine 0.1g, pomelo peel fermented product 17g, japonica rice extract 25g, betaine 0.08g, lotus leaf fermented product 13g, Marble powder 0.2g;

[0039] The fermented product of pomelo peel is that grapefruit peel and water are mixed at high speed according to the mass ratio of grapefruit peel: water=1:1.2 to make grapefruit peel slurry, and after the magnetic field strength is 1T DC stable strong magnetic field treatment for 10s, press 1.1 ×10 7 The amount of cfu / mL was inoculated with beer yeast and fermented for 3 days at a temperature of 20°C, and then treated with a DC constant magnetic field with a magnetic field strength of 4T for 5 seconds, and then pressed 2.6×10 6 The amount of cfu / mL is inoculated with lactic acid bacteria and fermented for 3 days at a temperature of 22-28°C;

[0040] The lotus leaf fermented product is that lotus leaf and wate...

Embodiment 3

[0049] A foaming agent for foam concrete, which is composed of the following raw materials: washing powder 9g, egg white 3g, colchicine 0.2g, grapefruit peel fermented product 17-20g, japonica rice extract 25-30g, betaine 0.14g, lotus leaf Fermentation product 14g, marble powder 0.25g;

[0050] The grapefruit peel fermented product is that grapefruit peel and water are mixed at high speed according to the mass ratio of grapefruit peel: water=1:1.5 to make grapefruit peel slurry, and after the magnetic field strength is 2T DC stable strong magnetic field treatment for 12s, press 1.3 ×10 7 The amount of cfu / mL was inoculated with beer yeast and fermented for 4 days at a temperature of 25°C, and then treated with a DC constant magnetic field with a magnetic field strength of 4.5T for 8s, and then pressed 2.9×10 6 The amount of cfu / mL was inoculated with lactic acid bacteria and fermented for 4 days at a temperature of 25°C;

[0051] The lotus leaf fermented product is that lotu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com