Device and method for preparing building structure based on 3D printing

A 3D printing and building structure technology, applied in the field of engineering and construction, can solve problems such as poor mechanical bonding performance of the interface between cement-based materials, and achieve the effect of improving efficiency and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

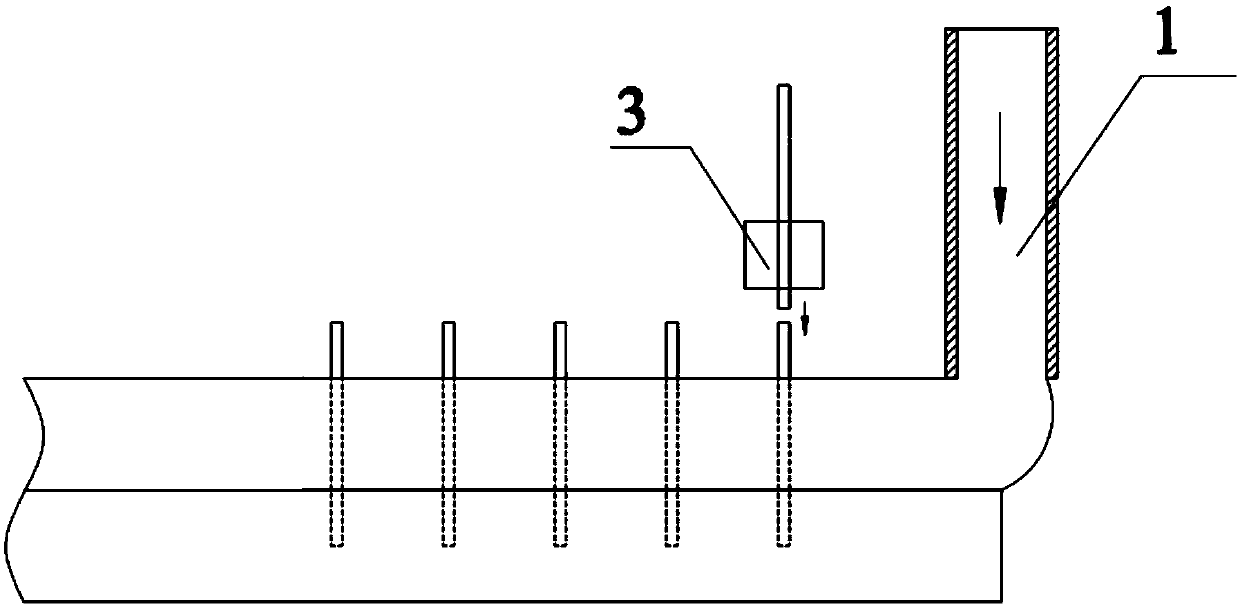

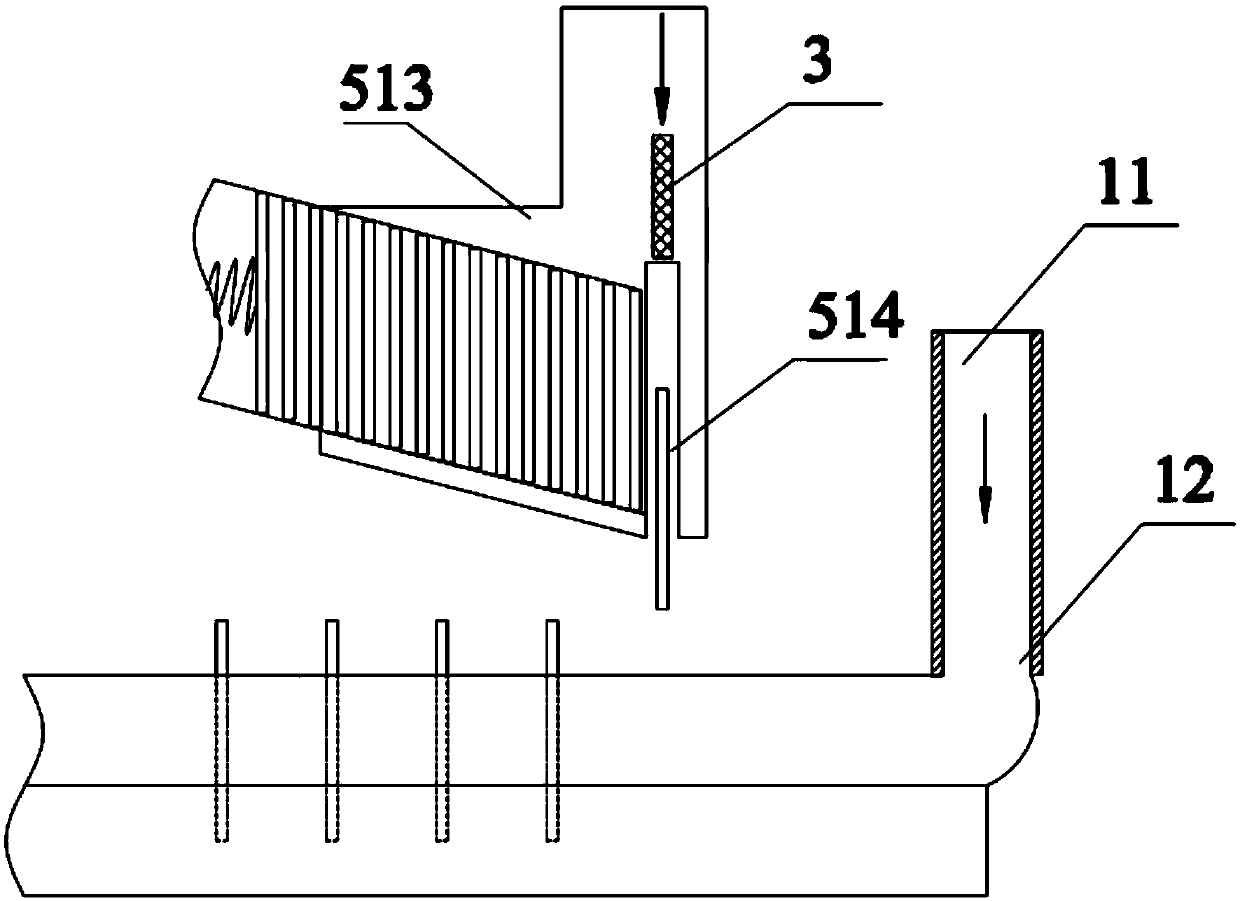

[0073] This embodiment provides a device for preparing building structures based on 3D printing, such as figure 2 and image 3 As shown, it includes: 3D printing device 1 and reinforcement device.

[0074] Among them, such as figure 2 As shown, the 3D printing device 1 has a material storage chamber 11 inside, and accommodates cement-based materials to be printed. The end of the material storage chamber 11 is connected with a nozzle 12; the nozzle 12 and the reinforcement device are both moved relative to the base frame.

[0075]For example, the 3D printing device as a whole or the nozzle is set on the moving mechanism, which moves relative to the base frame under the drive of the moving mechanism. The moving mechanism can include a lift and a manipulator fixed on the lift, or a sliding part fixed on the lift. Optionally, it can be a cylinder, and the nozzle is fixed on the telescopic shaft of the cylinder, so as to realize the movement of the nozzle of the 3D printing dev...

Embodiment 2

[0109] The equipment for preparing building structures based on 3D printing provided by this embodiment, such as Figure 5 and Image 6 , which includes: a 3D printing device 1 and a reinforcement device.

[0110] Compared with the equipment for preparing building structures based on 3D printing provided in Example 1, the difference is that the temporary storage mechanism in Example 1 is not provided in the reinforcing device. However, in the equipment for preparing a building structure based on 3D printing provided in this embodiment, the reinforcement device includes a straightening mechanism 4 and a cutting assembly 2 .

[0111] Wherein, the cutting assembly 2 is used for cutting long steel bars or long bars into short steel bars or short bars. The straightening mechanism 4 has a straight channel extending along the conveying direction of the long steel bar or the long bar and passing through by the long steel bar or the long bar, so as to adjust the levelness or vertical...

Embodiment 3

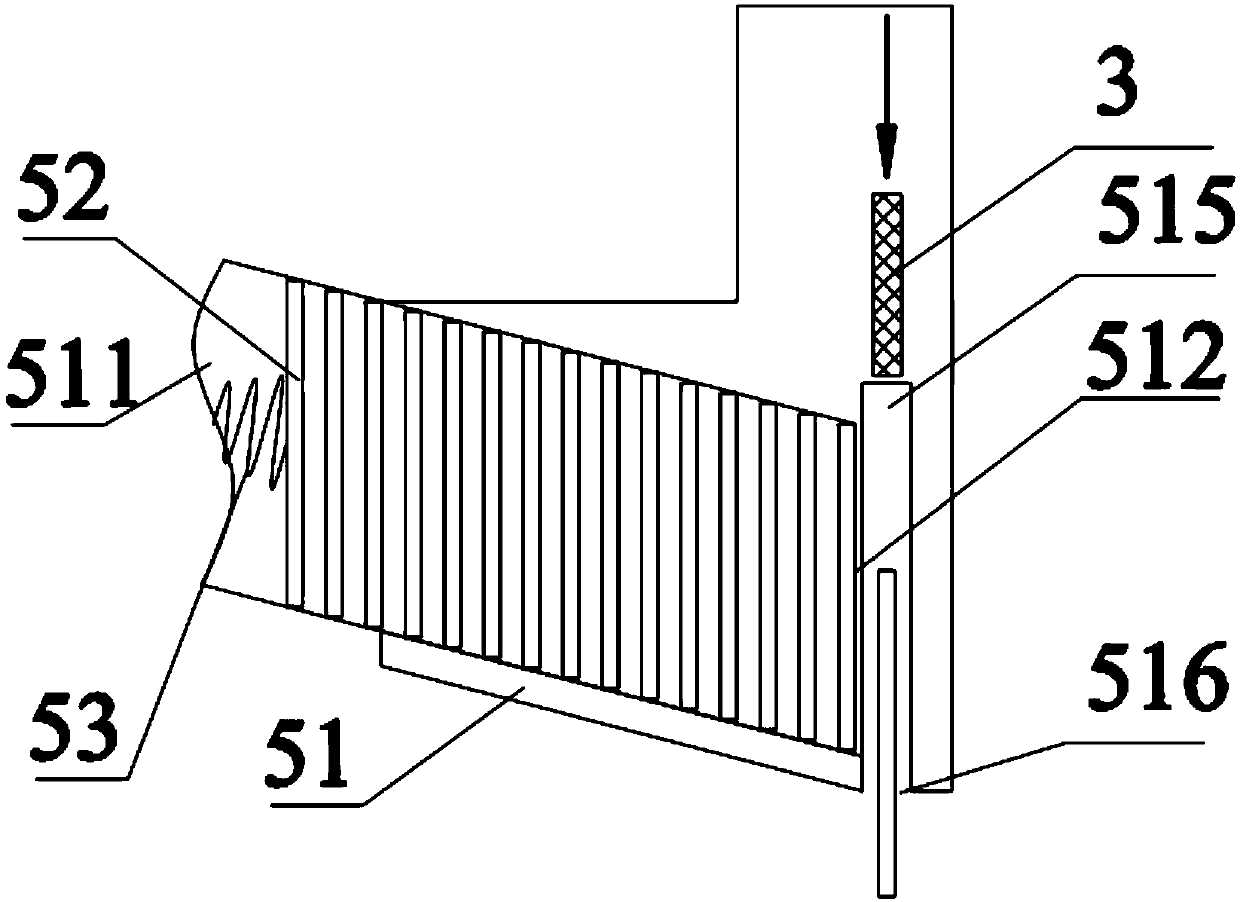

[0122] The equipment for preparing building structures based on 3D printing provided by this embodiment, such as Figure 7 , Figure 9a as well as Figure 9b As shown, it includes: 3D printing device 1 and reinforcement device.

[0123] Compared with the equipment for preparing building structures based on 3D printing provided in Example 2, the difference is that the setting position and setting direction of the straightening mechanism 4 of the reinforcement device and the cutting assembly 2 change; the setting direction of the driving mechanism 3 The setting forms are different. In addition, the reinforcement device also includes a bending mechanism 6 and a feeding mechanism 7 .

[0124] like Figure 7 As shown, the reinforcing device includes a driving mechanism 3 , a straightening mechanism 4 , a cutting assembly 2 , a bending mechanism 6 and a feeding mechanism 7 . Wherein, the feeding mechanism 7 is arranged before the straightening mechanism 4 to drive the long steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com