Pipeline cleaning robot

A technology of robots and pipelines, applied in the direction of removing smoke and dust, cleaning hollow objects, cleaning methods and utensils, etc., can solve problems such as unfavorable operations, achieve the effects of ensuring stability, ensuring cleaning effects, and simplifying the adjustment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

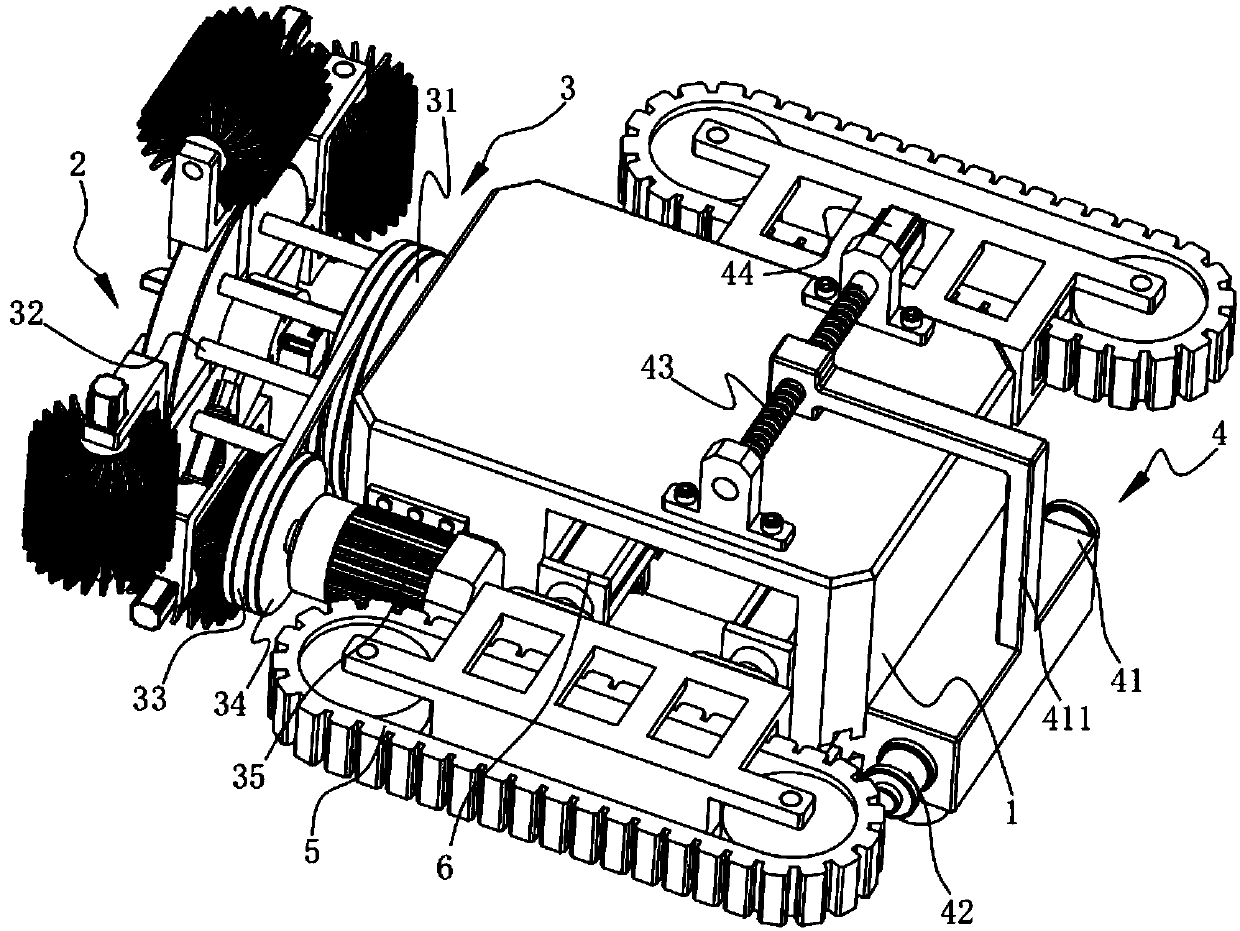

[0028] see Figure 1 to Figure 6 , the present invention provides a technical solution:

[0029] A pipeline cleaning robot, comprising a car body 1, a telescopic cleaning device 2, a drive mechanism 3, a dust collection device 4, a crawler mechanism 5 and a hydraulic cylinder I6, wherein:

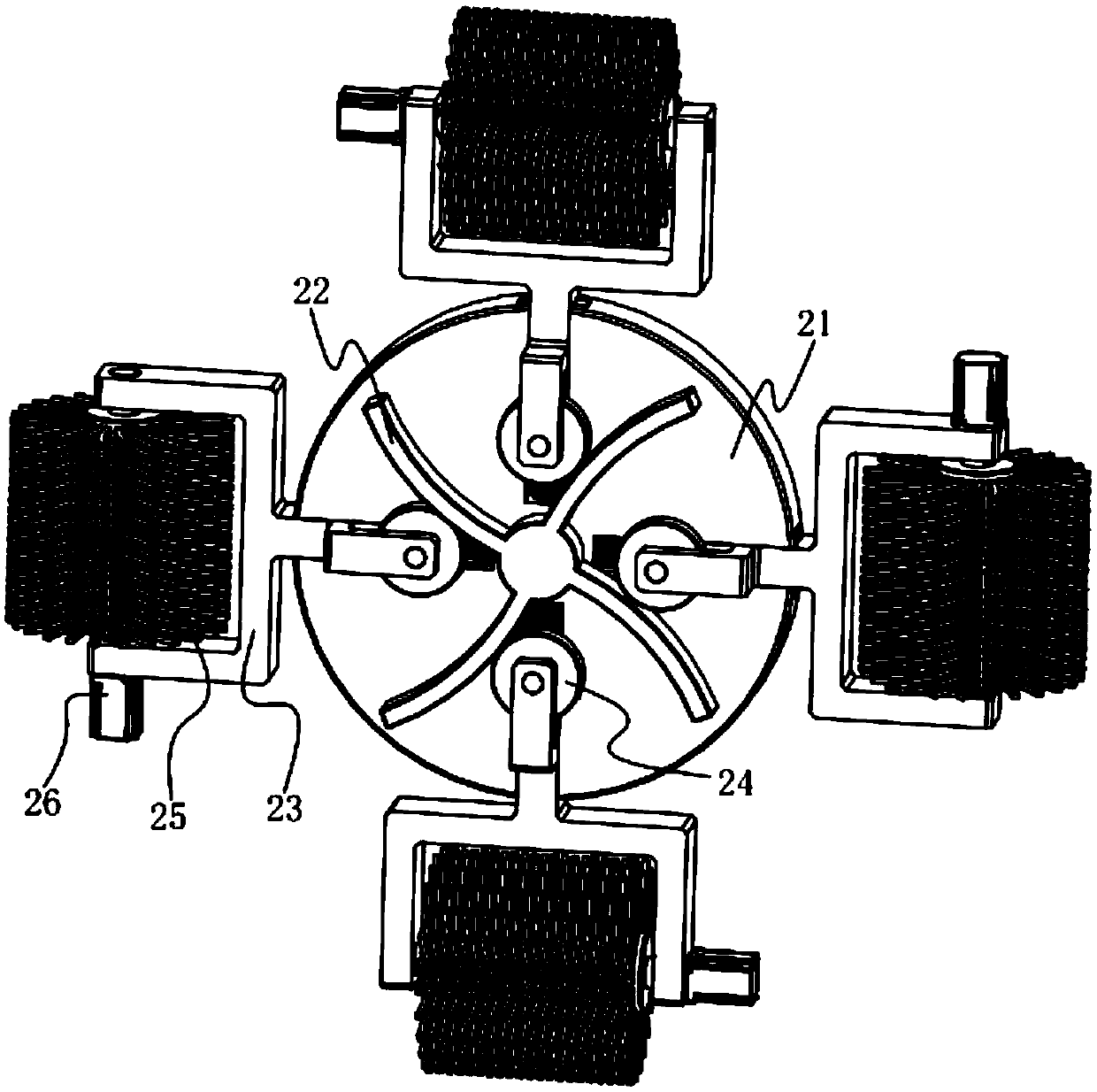

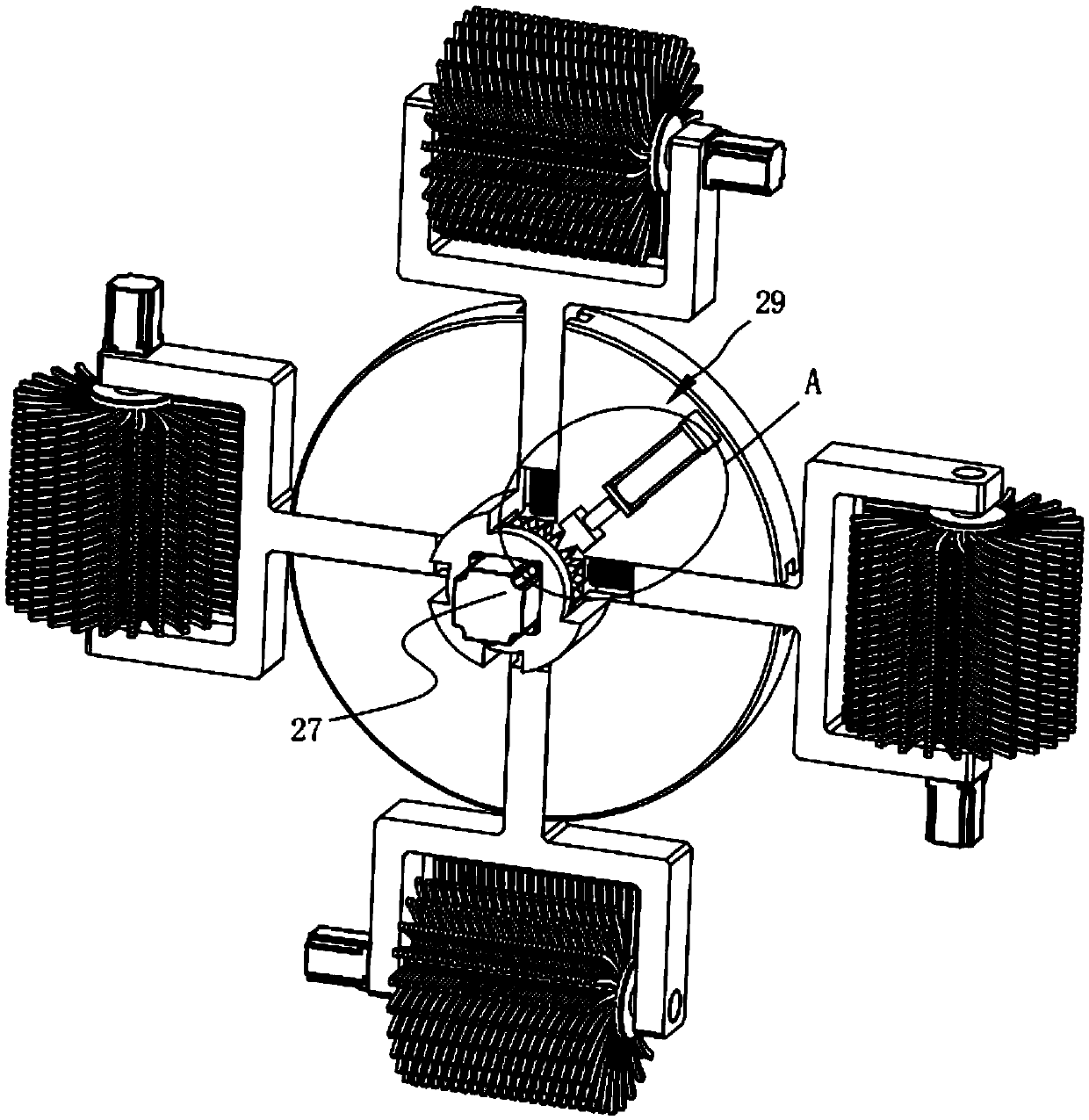

[0030] Telescopic cleaning device 2 comprises rotating disk 21, plectrum 22, sliding support 23, roller 24, hairbrush 25, motor I 26, motor II 27, spring 28 and limit mechanism 29, the tail end of plectrum 22 is provided with support shaft, plectrum The support shaft at the tail end of 22 is installed on the turntable 21 through bearings and passes through the turntable 21, thereby realizing the rotation of the dial 22 and being installed on the turntable 21, and the dial 22 is provided with four arc-shaped stoppers and four sliding brackets at equal angles. 23 equiangular activities are installed in the guide rail on the rotating disk 21, and the bottom of the sliding bracket 23 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com