Two-dimensional compliant vibration platform with wedge pre-tightening

A vibrating platform and supple technology, which is applied in the direction of the fluid that utilizes vibration, can solve the problems of the micro-milling machine, such as the great influence on the stiffness of the whole machine, the unintuitive adjustment of the pre-tightening force, and the large size of the ultrasonic horn. The overall size is small and the effect of the rigidity of the whole machine is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

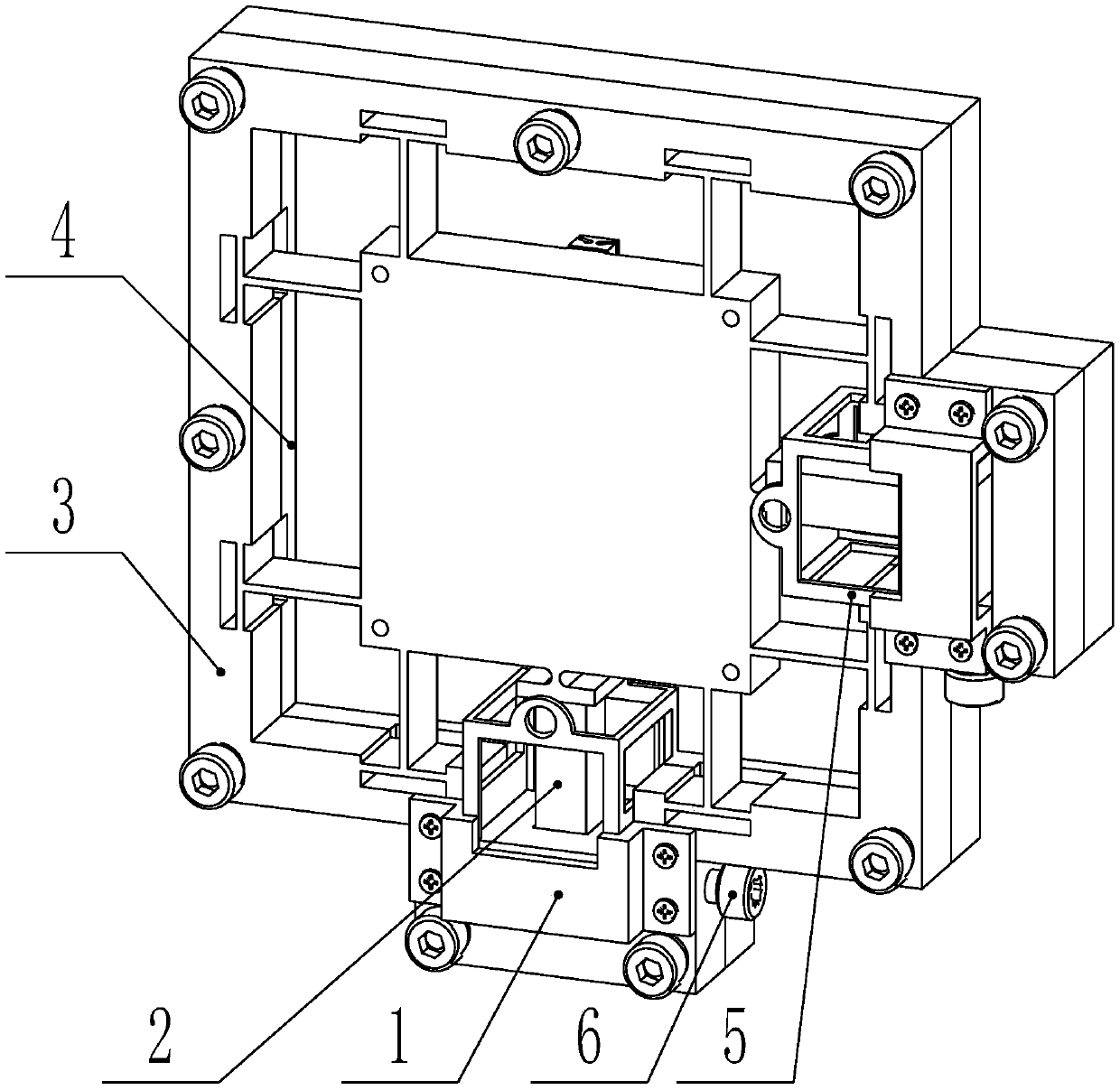

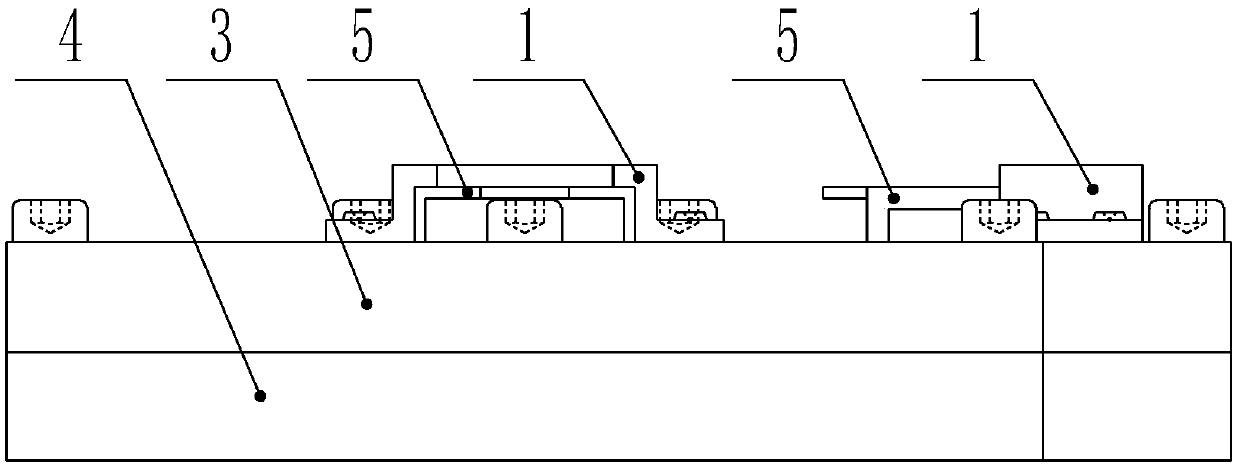

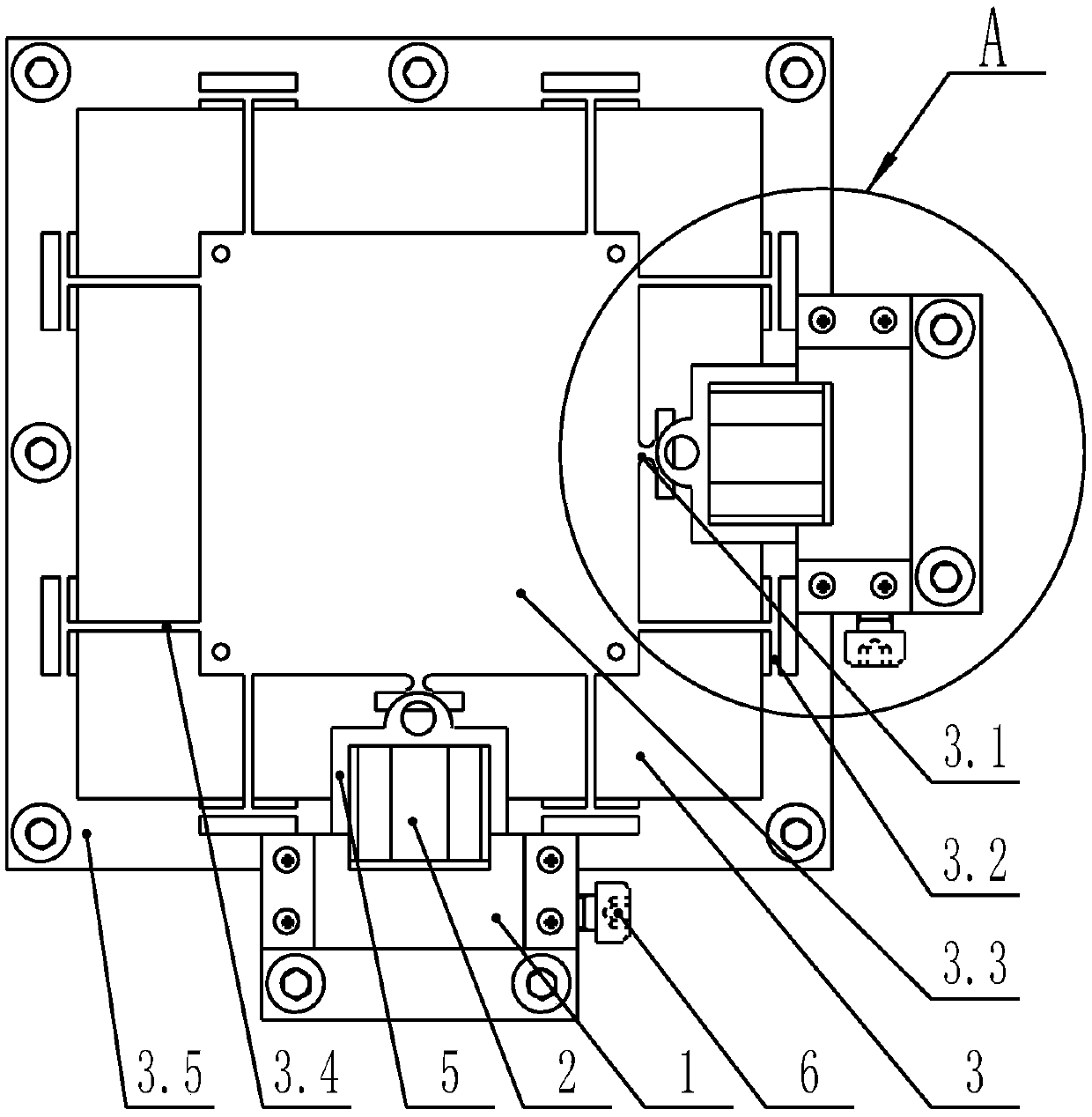

[0020] The invention provides a wedge-shaped preloaded two-dimensional compliant vibration platform (see Figure 1-4 , referred to as the vibration platform), which is characterized in that the vibration platform includes a driving source 2, a compliant vibration platform 3, a base 4 and a wedge-shaped pretensioning device 5; Flexible hinge 3.2, workbench 3.3, inner straight beam type flexible hinge 3.4 and outer frame body 3.5 of the compliant vibration platform;

[0021] The outer frame body 3.5 of the compliant vibration platform is connected to the base 4 through connectors (screws in this embodiment); the workbench 3.3 is located in the middle of the compliant vibration platform 3, and the inner straight beam type flexible hinge 3.4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com