Vacuum varnish dipping method for oil tank oil measurement sensor plastic pipe

A technology of oil quantity sensor and plastic tube, which is applied in the field of dipping paint, can solve the problems of low manufacturing cost and achieve the effect of improving mechanical strength, not easy to block, and avoiding vacuum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

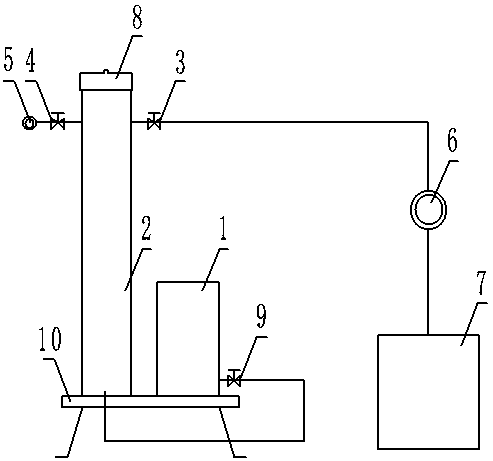

[0021] combined with figure 1 Shown, a kind of method for vacuum impregnating paint of plastic pipe of fuel tank fuel quantity sensor, comprises the following steps:

[0022] Step S1: Configure insulating varnish, mix the two components of polyurethane varnish evenly, and at the same time, mix it with cyclohexanone or polyurethane thinner according to the viscosity of the configuration, wait for 30 minutes to mature and use it after the bubbles disappear. And use it up within 8 hours.

[0023] After the insulating paint is prepared, it needs to be used within 8 hours. The container used for the paint preparation must be dry and clean; it is forbidden to contact with water, acid, alkali, alcohol, etc. during the paint preparation and immersion process; use cyclohexanone or X-10 polymer Urethane thinner to adjust the viscosity of the paint, do not use alcohol solvents as thinner; polyurethane thinner is X-10 polyurethane thinner.

[0024] Step S2: cleaning the paint dipping de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com