Preparation method of hierarchical porous Beta molecular sieve and Ni catalyst for hydrogen production by ethanol steam reforming

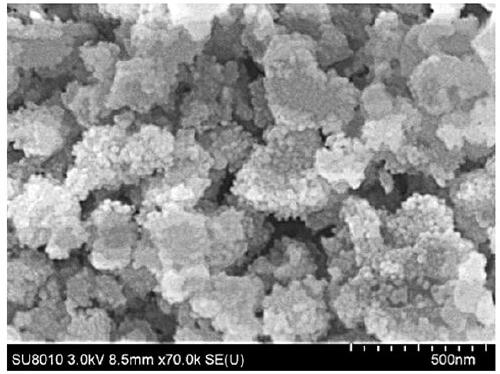

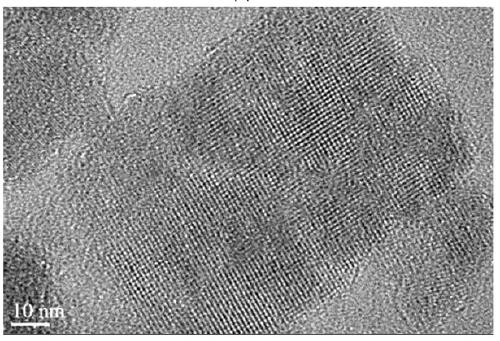

A steam reforming and multi-level pore technology is applied in the preparation of catalysts and in the field of multi-level porous molecular sieves, which can solve the problems of easy sintering, agglomeration and deactivation of nickel-based catalysts, carbon deposition, and low utilization rate of pore structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: The preparation method of multi-stage porous Beta molecular sieve for hydrogen production by steam reforming of ethanol, comprising the following steps:

[0034] 1) Dissolve 0.2mol of 1-bromododecane and 0.1mol of tetramethylhexamethylenediamine in 50mL of a mixed solution of toluene and acetonitrile with a volume ratio of 1:1, and reflux in a water bath at 70°C 48h; cooled to room temperature, the solid product was filtered and washed with cold ether solution, and the obtained white solid was vacuum-dried at 50°C for 5h, and the obtained white gemini surfactant [C 12 h 25 (CH 3 ) 2 N + (CH 2 ) 6 N + (CH 3 ) 2 C 12 h 25 ][Br] 2 - [C 12 h 25 (CH 3 ) 2 N + (CH 2 ) 6 N + (CH 3 ) 2 C 12 h 25 ][Br] 2 - Soluble in deionized water; through anion exchange resin, transparent [C 12 h 25 (CH 3 ) 2 N + (CH 2 ) 6 N + (CH 3 ) 2 C 12 h 25 ][OH] 2 - solution, the above [C 12 h 25 (CH 3 ) 2 N + (CH 2 ) 6 N + (CH 3 ) 2 C 12...

Embodiment 2

[0049] Embodiment 2: the preparation method of multi-stage porous Beta molecular sieve for hydrogen production by steam reforming of ethanol, comprising the following steps:

[0050] 1) Dissolve 0.2mol of 1-bromododecane and 0.1mol of tetramethylhexamethylenediamine in 50mL of a mixed solution of toluene and acetonitrile with a volume ratio of 1:1, and reflux in a water bath at 70°C 48h; cooled to room temperature, the solid product was filtered and washed with cold ether solution, and the obtained white solid was vacuum-dried at 50°C for 5h, and the obtained white gemini surfactant [C 12 h 25 (CH 3 ) 2 N + (CH 2 ) 6 N + (CH 3 ) 2 C 12 h 25 ][Br] 2 - [C 12 h 25 (CH 3 ) 2 N + (CH 2 ) 6 N + (CH 3 ) 2 C 12 h 25 ][Br] 2 - Soluble in deionized water; through anion exchange resin, transparent [C 12 h 25 (CH 3 ) 2 N + (CH 2 ) 6 N + (CH 3 ) 2 C 12 h 25 ][OH] 2 - solution, the above [C 12 h 25 (CH 3 ) 2 N + (CH 2 ) 6 N + (CH 3 )2 C 12 h...

Embodiment 3

[0065] Embodiment 3: the preparation method of multi-stage porous Beta molecular sieves for hydrogen production by steam reforming of ethanol, comprising the following steps:

[0066] 1) Dissolve 0.2mol of 1-bromododecane and 0.1mol of tetramethylhexamethylenediamine in 50mL of a mixed solution of toluene and acetonitrile with a volume ratio of 1:1, and reflux in a water bath at 70°C 48h; cooled to room temperature, the solid product was filtered and washed with cold ether solution, and the obtained white solid was vacuum-dried at 50°C for 5h, and the obtained white gemini surfactant [C 12 h 25 (CH 3 ) 2 N + (CH 2 ) 6 N + (CH 3 ) 2 C 12 h 25 ][Br] 2 - [C 12 h 25 (CH 3 ) 2 N + (CH 2 ) 6 N + (CH 3 ) 2 C 12 h 25 ][Br] 2 - Soluble in deionized water; through anion exchange resin, transparent [C 12 h 25 (CH 3 ) 2 N + (CH 2 ) 6 N + (CH 3 ) 2 C 12 h 25 ][OH] 2 - solution, the above [C 12 h 25 (CH 3 ) 2 N + (CH 2 ) 6 N + (CH 3 ) 2 C 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com