Catalyst for side-chain alkylation of toluene and methanol, method for preparing styrene

An alkylation reaction and catalyst technology, applied in the field of styrene preparation and catalyst, can solve the problems of low toluene conversion rate and methanol decomposition, and achieve the effects of improving reaction activity, improving stability and improving hydrothermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Example 1 Alkali metal ion-doped ordered mesoporous molecular sieve catalyst sample B-1 # ~B-8 # preparation of

[0075] Sample preparation steps of ordered mesoporous molecular sieve catalyst doped with alkali metal ions:

[0076] Weigh 29.84g of sodium silicate and 7.64g of cetyltrimethylammonium bromide, add deionized water and heat to 35°C under stirring to dissolve;

[0077] Add it to 250mL of nitrate solutions of different alkali metal ions and mix evenly. After continuing to stir for 30 minutes, transfer the resulting solution to a reaction kettle and place it in an oven at 145°C for hydrothermal crystallization for 48 hours.

[0078] After cooling to room temperature, the product was filtered, washed, dried at 110°C, and then heated at 2°C / min to 550°C for 4 hours in an air atmosphere to obtain MCM-41 molecular sieve samples doped with different alkali metal ions, respectively denoted as B-1 # ~B-8 # .

[0079] Obtained sample B-1 # ~B-8 # After being gro...

Embodiment 2

[0083] Embodiment 2 is used for the preparation step of the catalyst of toluene methanol side chain alkylation reaction

[0084] The metal oxide is loaded onto the surface of the MCM-41 molecular sieve doped with alkali metal ions, and the preparation steps are as follows:

[0085] Weigh 50g of MCM-41 molecular sieve doped with alkali metal ions, divide it into several parts according to the mass, and then impregnate and add an aqueous nitrate solution corresponding to the metal oxide by equal volume.

[0086] Soak overnight at room temperature, dry the resulting mixture at 110°C, then heat up to 550°C for 4 hours in an air atmosphere at 10°C / min. Reserved. The supported metal oxides are numbered C-1 according to the type of different metal oxides # ~C-8 # .

[0087] Table 2 shows the numbers of the supported metal oxides, the types of supported metal oxides, the mixing mass ratio, and the loading amount. The mixing ratio is calculated according to the mass of the support...

Embodiment 3

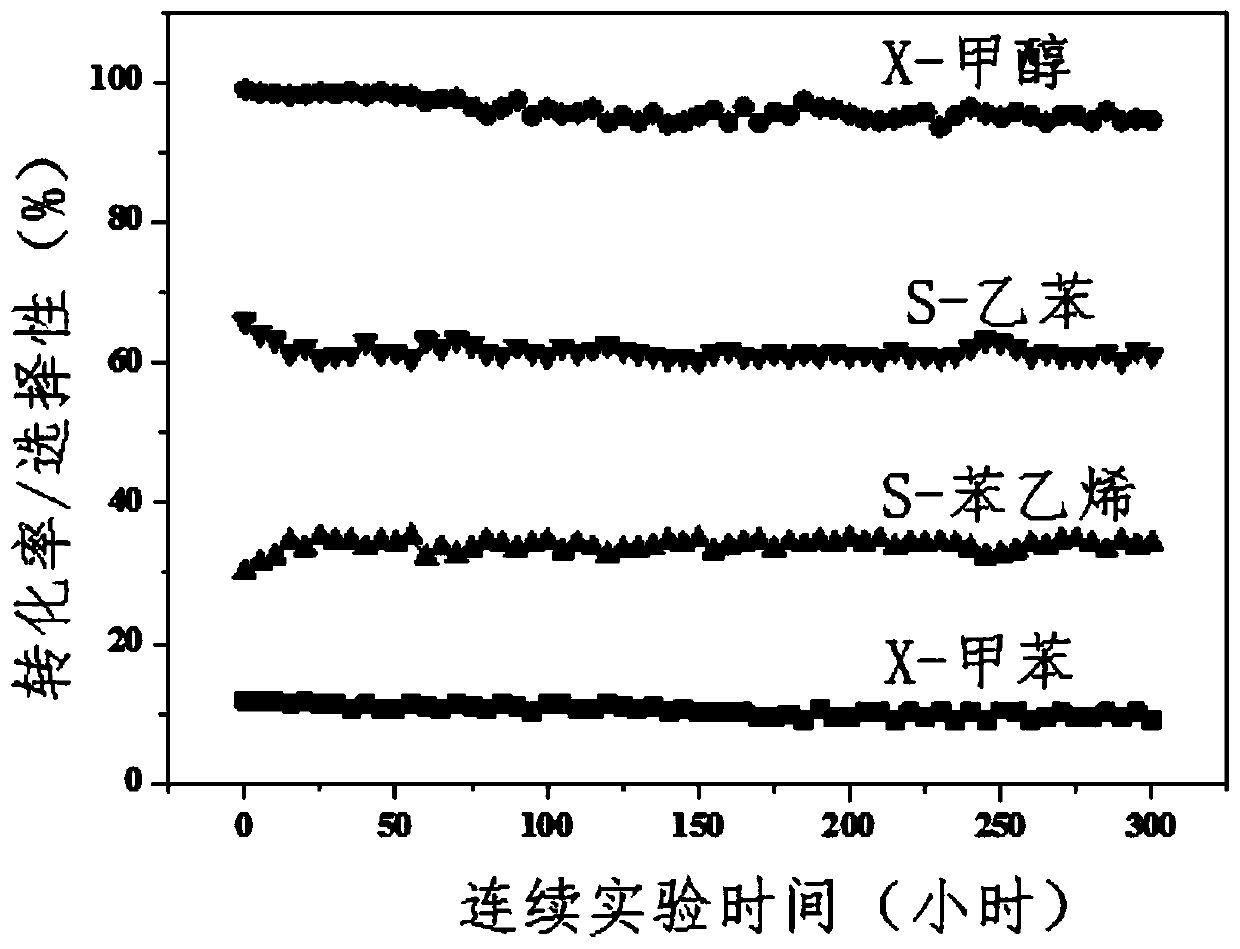

[0090] Embodiment 3 catalyst sample CAT-1 # ~CAT-16 # Evaluation

[0091] Mesoporous molecular sieve sample B-1 doped with alkali metal ions # ~B-8 # Combinations with supported metal oxides are listed in Table 3.

[0092] Obtain catalyst sample CAT-1 with reference to the method in embodiment 2 # ~CAT-16 # .

[0093] 1.2 g of the selected samples were packed in the constant temperature zone of a small fixed-bed reactor, and quartz sand was filled at both ends of the reactor.

[0094] table 3

[0095]

[0096]

[0097] After filling the reactor, the catalyst bed was first activated at 550°C for 1 hour under a helium atmosphere (40ml / min), then cooled down to the reaction temperature, and the raw materials toluene and methanol were introduced with a micro feed pump, and the feed moles of toluene and methanol were The ratio, space velocity, reaction pressure and reaction temperature are shown in Table 4.

[0098] The product was detected by an Agilent 7890A gas ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com