Organic-inorganic self-solidified composite bone graft formed by hydration bridge formation of multi-trace element organic compound and inorganic compound

A bone graft and compound technology, applied in the field of biomedical materials, can solve the problems of small selectivity, disappearance, single function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Experimental steps:

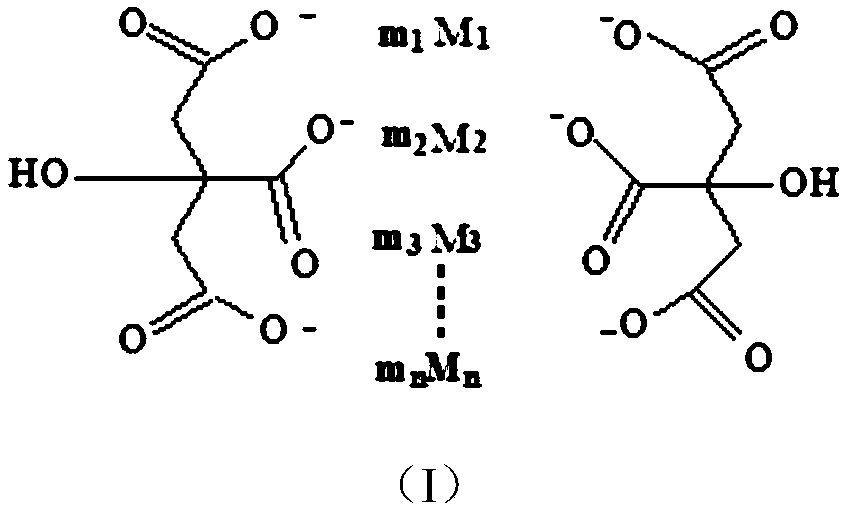

[0065] (1) Add 5000mL of pure water into a 10L glass reactor, stir under the protection of nitrogen, and gradually add 384.28 g of 3-hydroxy-1,3,5-pentanetriic acid. After it is completely dissolved, add in order: 125.42g ZnCO 3 ; After stirring for 20 minutes, add 200.18g CaCO 3 , stir and gradually raise the temperature to 60°C, adjust the pH value to 7.5-8.0 with ammonia water, then maintain for 4 hours, then gradually cool to room temperature naturally, seal the reactor and keep for 48 hours. Then the supernatant was removed by filtration, the precipitate was washed 4 times with 3000ml pure water, and then washed twice with 3000mL absolute ethanol, then dried at 120°C for 12 hours under the protection of nitrogen, and then dried at 100°C for 12 hours in a vacuum oven. Obtain 436.05 g of multi-trace element organic compound of structure shown in formula (I), in this formula (I) structural compound m 1 = 1, M 1 = Zn; m 2 = 2, M 2 = Ca; m 3...

Embodiment 2

[0074] Experimental steps:

[0075] (1) get the product 50g of (I) of anhydrous structure in the above-mentioned embodiment 1 and mix with 50g anhydrous calcium hydrogen phosphate, finely grind 2 hours by ball mill, obtain 96g to have structure (II) multi-trace element organic compound and inorganic Organic-inorganic self-solidifying composite bone graft formed by compound through hydration bridging, wherein M i = Ca, X = HPO 4 2- .

[0076] (2) Take 10g of the above structure (II) multi-trace element organic compound and inorganic compound organic-inorganic self-solidifying composite bone graft, add 5mL of pure water, stir, and after 3 minutes it becomes a dough state, and put it into a φ3×5mm mold , 30 minutes out. Hydration occurs by adding pure water, and the structure (II) is transformed into an organic-inorganic self-solidifying composite bone graft structure (III) formed by hydration bridging of multi-trace element organic compounds and inorganic compounds.

[0077...

Embodiment 3

[0084] Experimental steps:

[0085] (1) Add 5000mL of pure water into a 10L glass reactor, stir under nitrogen protection, and gradually add 384.28 g of 3-hydroxy-1,3,5-pentanetrionic acid. After it is completely dissolved, add 84g of MgCO 3 ; After stirring for 20 minutes, add 200.18g CaCO 3 , stir and gradually raise the temperature to 60°C, adjust the pH value to 7.5-8.0 with ammonia water, then maintain for 4 hours, then gradually cool to room temperature naturally, seal the reactor and keep for 48 hours. Then the supernatant was removed by filtration, the precipitate was washed 4 times with 3000ml pure water, and then washed twice with 3000mL absolute ethanol, then dried at 120°C for 12 hours under the protection of nitrogen, and then dried at 100°C for 12 hours in a vacuum oven. (I) of anhydrous structure was obtained: 420.12 g. m in (I) of the anhydrous structure of the multi-trace element organic compound1 = 1, M 1 = Mg; m 2 = 2, M 2 = Ca; m 3= 0, M 3 =0.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com