Composite silver nano-hydroxyapatite/alginate microspheres and preparation method thereof

A technology of hydroxyapatite and alginate, applied in the field of materials, can solve problems such as high toxicity, achieve good adsorption, strong operability, and no toxic side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

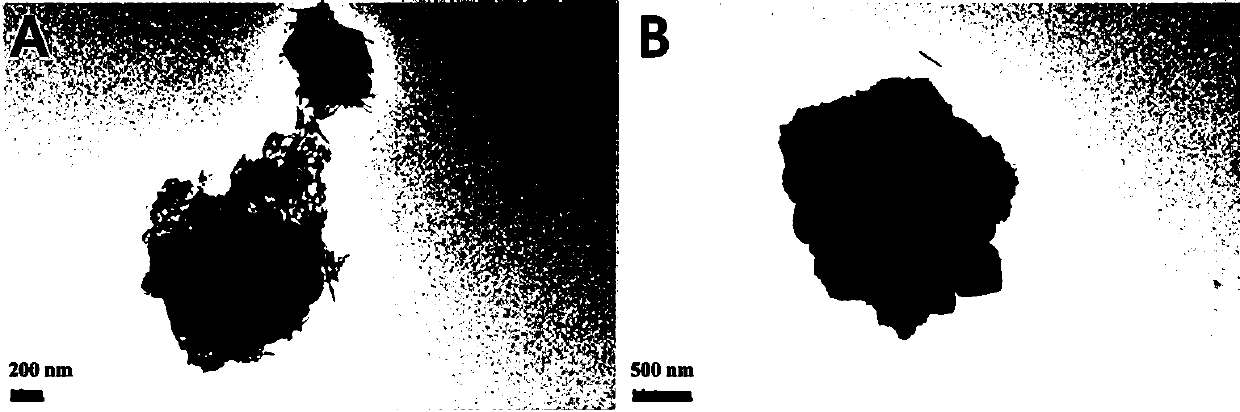

Image

Examples

Embodiment 1

[0027] A composite silver nano-hydroxyapatite / alginate microsphere, the microsphere uses hydroxyapatite as the core body, and sodium alginate is fixed in the porous structure of hydroxyapatite, and in the presence of silver ions cross-linked.

[0028] Its preparation method comprises the following steps:

[0029] (1) Sodium alginate was dissolved in ultrapure water at room temperature to prepare a sodium alginate solution with a mass concentration of 1% for subsequent use; silver nitrate was prepared into an aqueous solution of silver nitrate with a molar concentration of 0.75M in the dark Standby; put 0.15g of hydroxyapatite powder in a 50 mL centrifuge tube, add 12 mL of sodium alginate aqueous solution, stir at a high speed of 8000 rpm for 10 minutes at room temperature, and then centrifuge at a speed of 3000 rpm for 3 min at room temperature , the precipitate was washed 3 times with ultrapure water;

[0030] (2) Add 1 mL of silver nitrate aqueous solution to the precipit...

Embodiment 2

[0032] A composite silver nano-hydroxyapatite / alginate microsphere, the microsphere uses hydroxyapatite as the core body, and sodium alginate is fixed in the porous structure of hydroxyapatite, and in the presence of silver ions cross-linked.

[0033] Its preparation method comprises the following steps:

[0034] (1) Sodium alginate was dissolved in ultrapure water at room temperature to prepare a sodium alginate solution with a concentration of 1% for later use, and silver nitrate was prepared into an aqueous solution of silver nitrate with a molar concentration of 0.05M in the dark for later use ;

[0035] Put 0.15 g of hydroxyapatite powder in a 50 mL centrifuge tube, add 18 mL of sodium alginate aqueous solution, stir at a high speed of 15,000 rpm for 10 minutes at room temperature, and then centrifuge at 3,000 rpm for 3 minutes at room temperature. Wash with water 3 times;

[0036] (2) Add 10 mL of silver nitrate aqueous solution to the precipitate obtained in step (1)...

Embodiment 3

[0038] A composite silver nano-hydroxyapatite / alginate microsphere, the microsphere uses hydroxyapatite as the core body, and sodium alginate is fixed in the porous structure of hydroxyapatite, and in the presence of silver ions cross-linked.

[0039] Its preparation method comprises the following steps:

[0040] (1) Sodium alginate was dissolved in ultrapure water at room temperature to prepare a sodium alginate aqueous solution with a concentration of 1.5% for later use, and silver nitrate was prepared into a silver nitrate aqueous solution with a molar concentration of 0.1M for later use in the dark. ;

[0041] Put 0.15 g of hydroxyapatite powder in a 50 mL centrifuge tube, add 9 mL of sodium alginate solution, stir at 20,000 rpm at room temperature for 10 minutes at high speed, then centrifuge at 3,500 rpm at room temperature for 5 minutes, and wash with ultrapure water for 3 times ;

[0042] (2) Add 10 mL of silver nitrate aqueous solution to the precipitate obtained i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com