High-precision eccentricity eliminating focusing mechanism suitable for universal optical system

A general-purpose optical and high-precision technology, used in optics, optical components, installation, etc., can solve the problems of high requirements for rail processing and installation accuracy, achieve high bidirectional focus control accuracy, improve imaging quality, and reliable self-locking ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the present invention will be further described through embodiments in conjunction with the drawings.

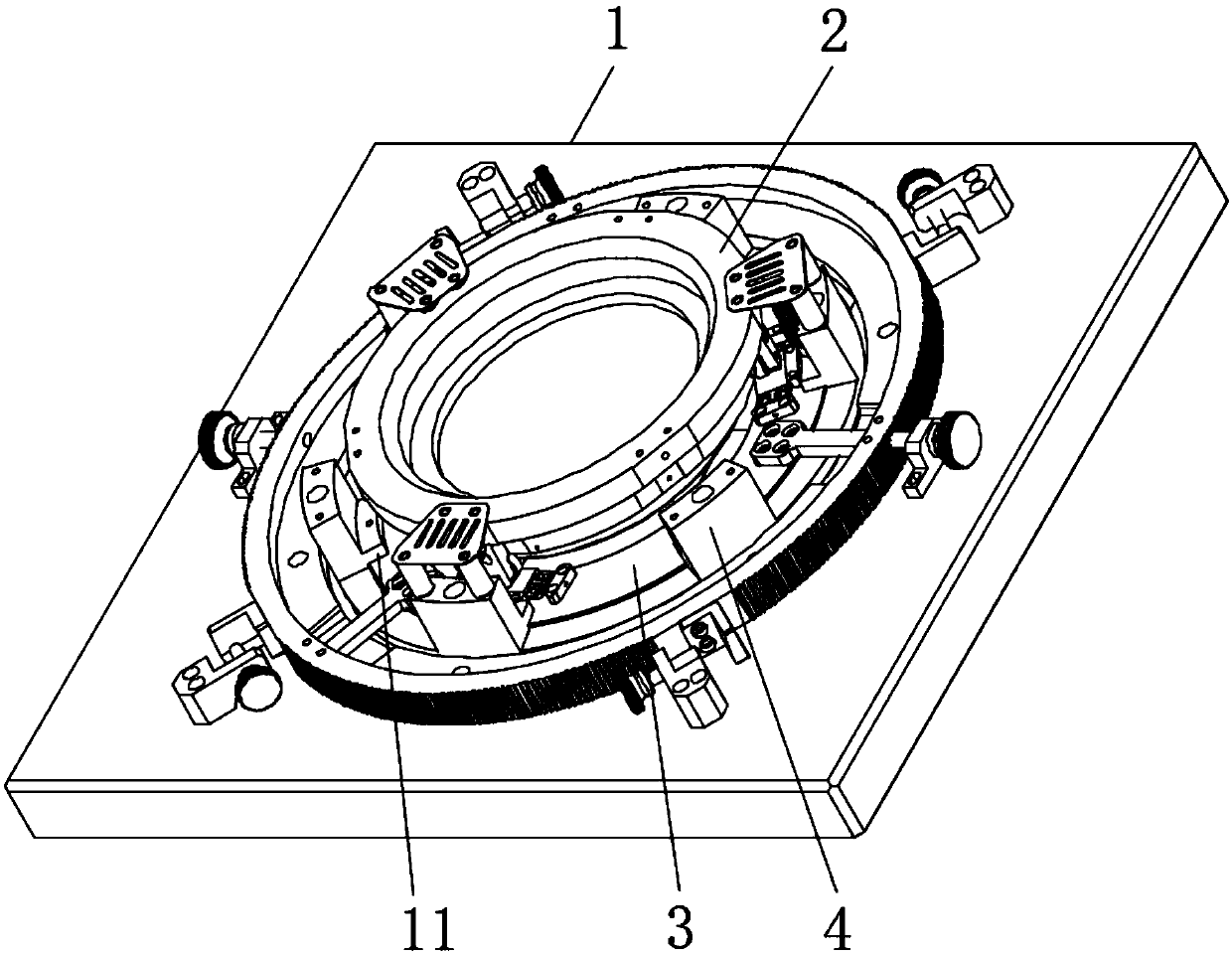

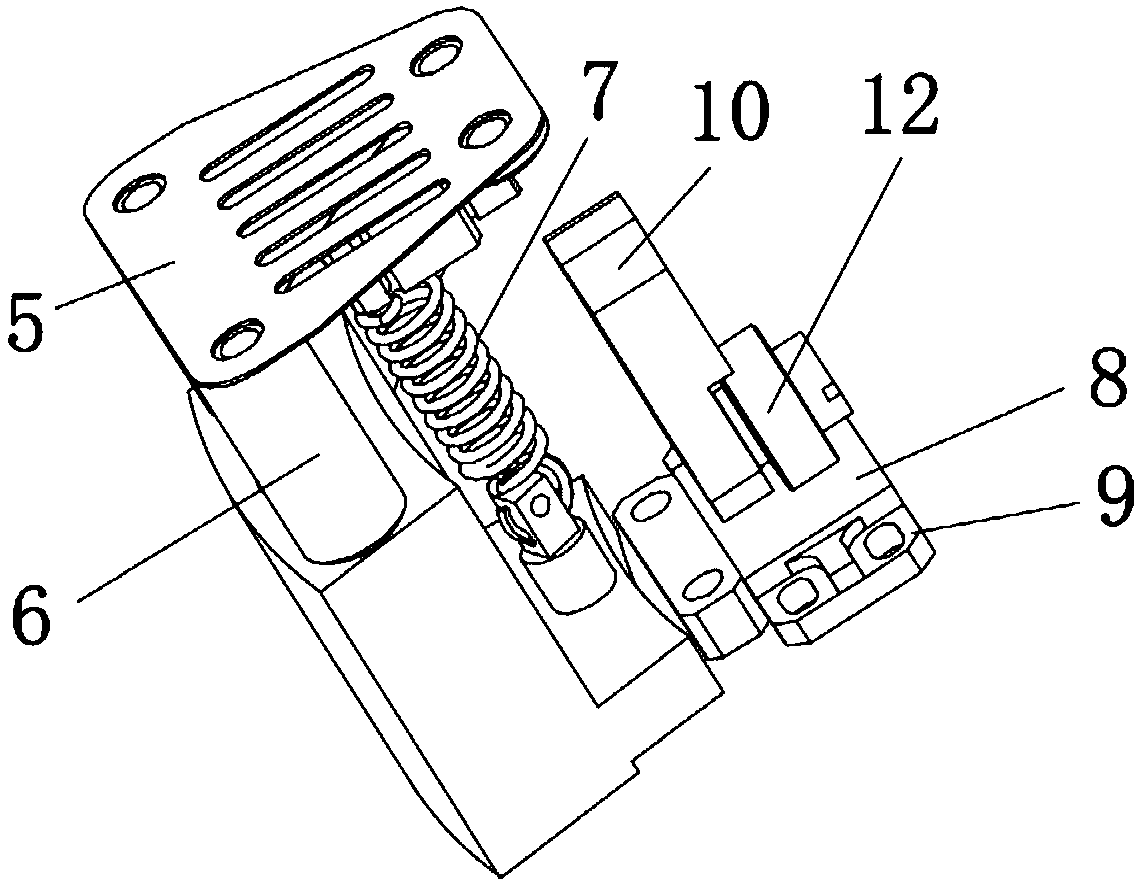

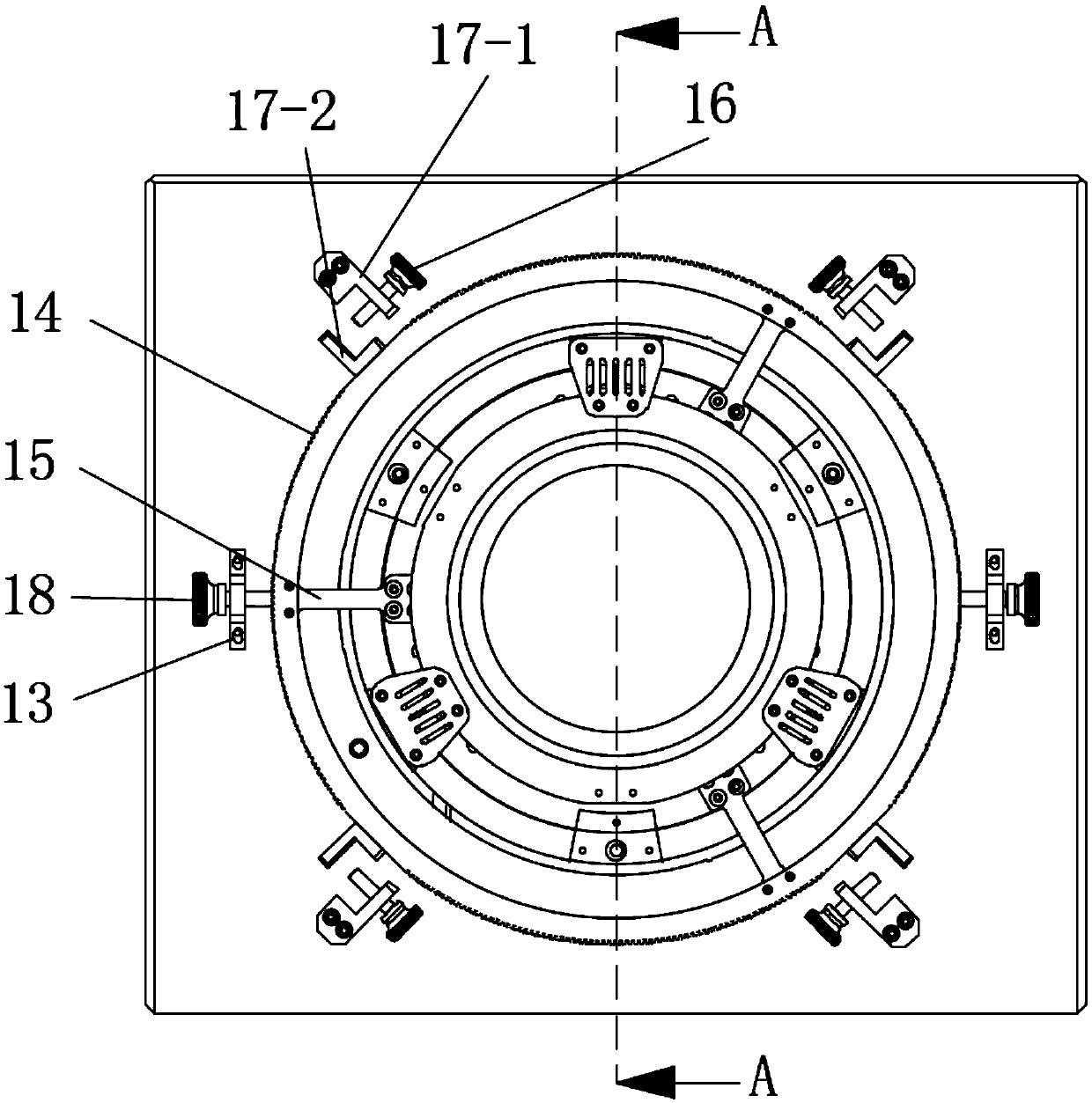

[0031] Refer to Figure 1-Figure 11 , This embodiment relates to a high-precision de-eccentric focusing mechanism suitable for general optical systems, including a base plate 1, a lens holder 2, a rotating disk 3, a rotating disk fixing seat 4, an elastic sheet 5, and an elastic sheet fixing column 6 , Spring 7, wedges 8, thrust bearing seat 10, bearing 12; the rotating disk holder 4 is fixedly mounted on the base plate 1, the rotating disk 3 is rotatably arranged on the rotating disk holder 4, and the lens holder 2 At least three thrust bearing seats 10 and three springs 7 are connected along the circumferential direction (six are shown in the figure and preferably evenly distributed along the circumferential direction). Each thrust bearing seat 10 is equipped with a bearing 12, the bearing 12 In contact with the wedge surface of the wedge 8, the wedge 8 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com