Four-gate continuous coiled tubing packer

A technology of well sealer and four rams, which is used in sealing/isolation, wellbore/well components, earth-moving drilling, etc., can solve the problem that the semi-sealing cannot fully restore the sealing performance, increase the volume of the wellhead device, and has a great impact and other problems, to achieve the effect of reducing personal trauma accidents, reducing processing costs, and convenient operation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

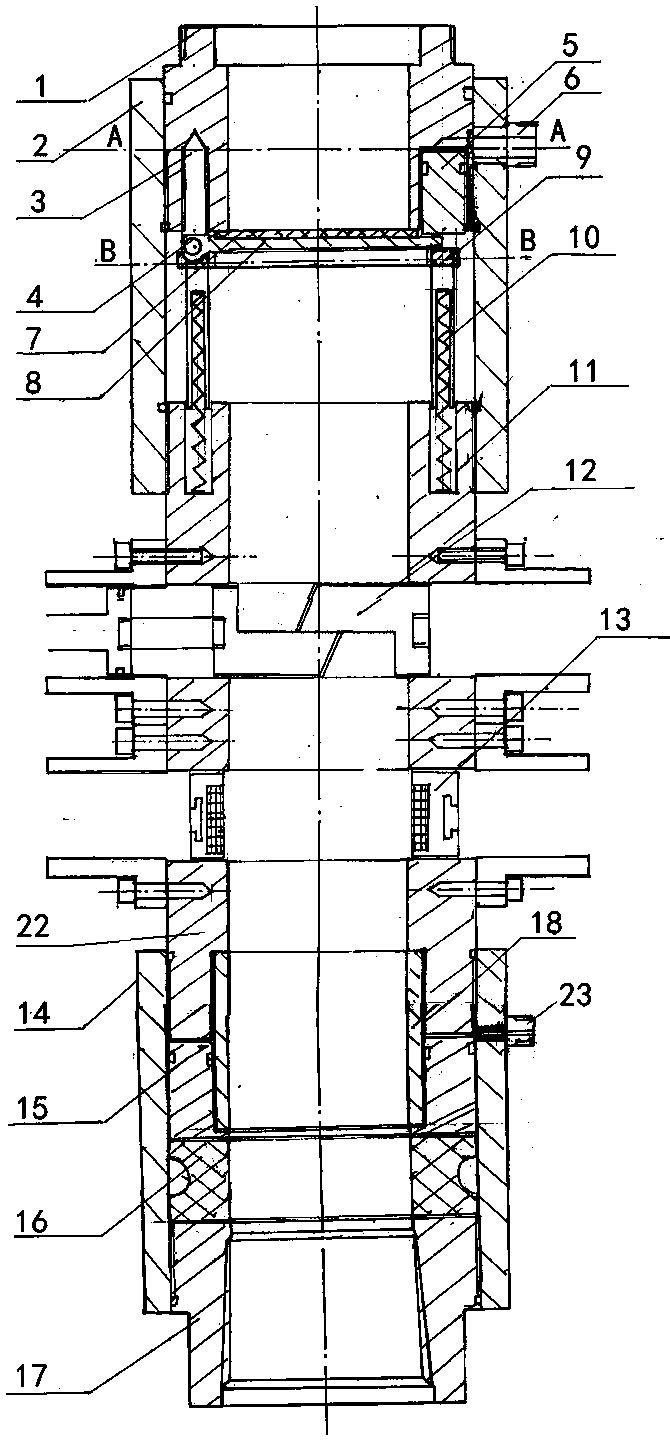

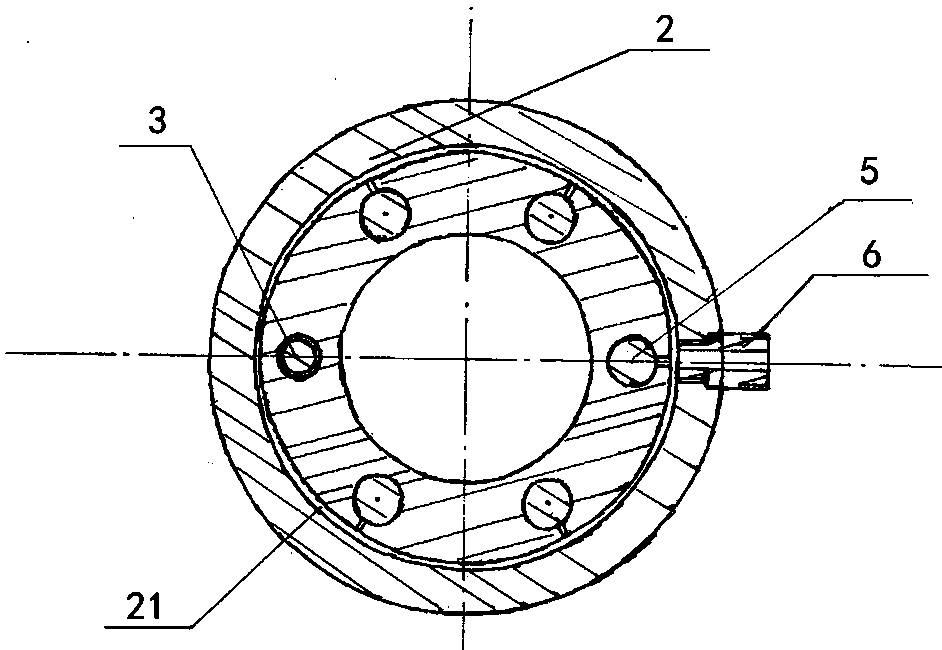

[0033] Embodiments 1-5, a coiled tubing well sealer with four rams mentioned in the present invention, its technical solution is: it includes a main housing 19 and a hydraulic cylinder 20, and the inner cavity of the main housing 19 is sequentially arranged from top to bottom Full-sealing device, shearing device, suspension device and semi-sealing device are installed, hydraulic cylinder 20 is installed on the outside of main housing 19, is used to drive full-sealing device, shearing device, suspension device or semi-sealing device action, described The fully sealed device includes upper joint 1, fully sealed outer cylinder liner 2, ram fixing bolt 3, ram shaft 4, ram opening piston group 5, connecting nozzle 6, sealing rubber 7, sealing carrier 8, ram closing bracket 9. The return spring 10 and the cutting and hanging body 11 are fixedly connected with the upper joint 1 and the cutting and hanging body 11 through the fully sealed outer cylinder liner 2, and there is a cavity f...

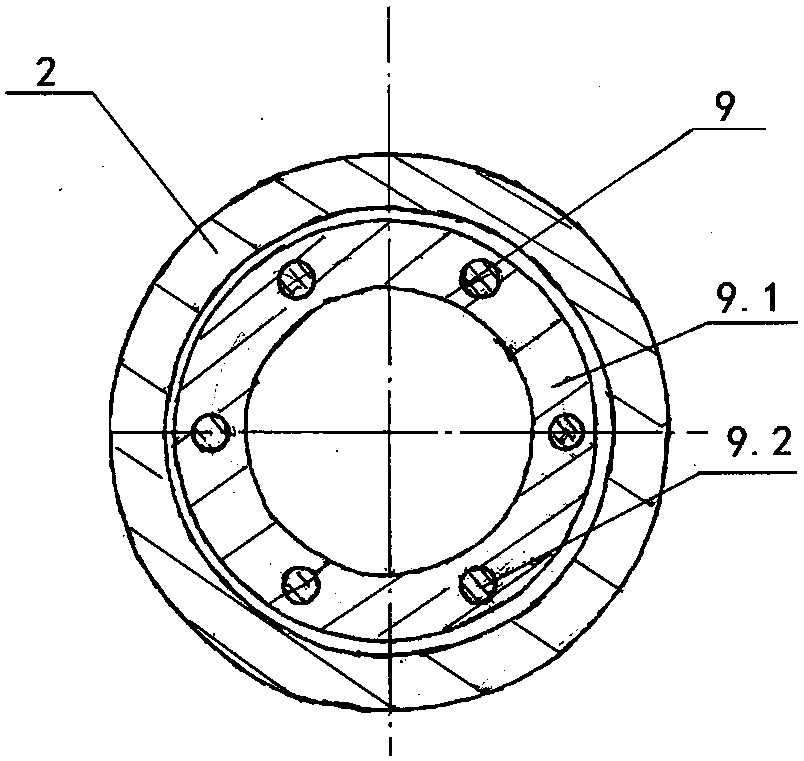

Embodiment 2

[0054] Embodiment 2, with reference to attached Image 6 , the difference between the present invention and Embodiment 1 is that a return force spring 10 is provided on the outside of the guide shaft 9.2, the lower end of the return force spring 10 is arranged on the upper end of the cutting and hanging body 11, and the upper end of the return force spring 10 is in contact with the lower surface of the connection plate 9.1 In this way, the guide shaft can also be moved up and down along the reserved cylindrical groove of the cutting and hanging body 11, and at the same time, the accumulated spring compression force can make the sealing ram be pressed to the lower end surface of the upper joint when the well is sealed; in addition , the guide shaft 9.2 provided here can adopt a solid structure, since it is not necessary to install a spring in the inner cavity of the guide shaft, it is not necessary to adopt a hollow structure.

Embodiment 3

[0055] Embodiment 3, with reference to attached Figure 7 , the difference between the present invention and embodiments 1 and 2 is: the sealing device used in the present invention adopts the full sealing device, shearing device and suspension device in embodiments 1 and 2, but what the half sealing device adopts is the existing The semi-enclosed device of technology, like this, the improvement of the present invention is just limited to full-enclosed device, specifically as follows:

[0056]The present invention comprises a main housing 19 and a hydraulic cylinder 20, and a full-sealing device, a shearing device, a suspension device and a half-sealing device are successively installed in the inner chamber of the main housing 19 from top to bottom, and a The hydraulic cylinder 20 is used to drive the action of the full-sealing device, the shearing device, the suspension device or the semi-sealing device. The full-sealing device includes an upper joint 1, a full-sealing outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com