Efficient steel-concrete combined bridge panel template structure and application method

A combined formwork and high-efficiency technology, used in bridges, bridge parts, bridge construction, etc., can solve the problems of different pouring construction methods, pin deformation, complex construction steps, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

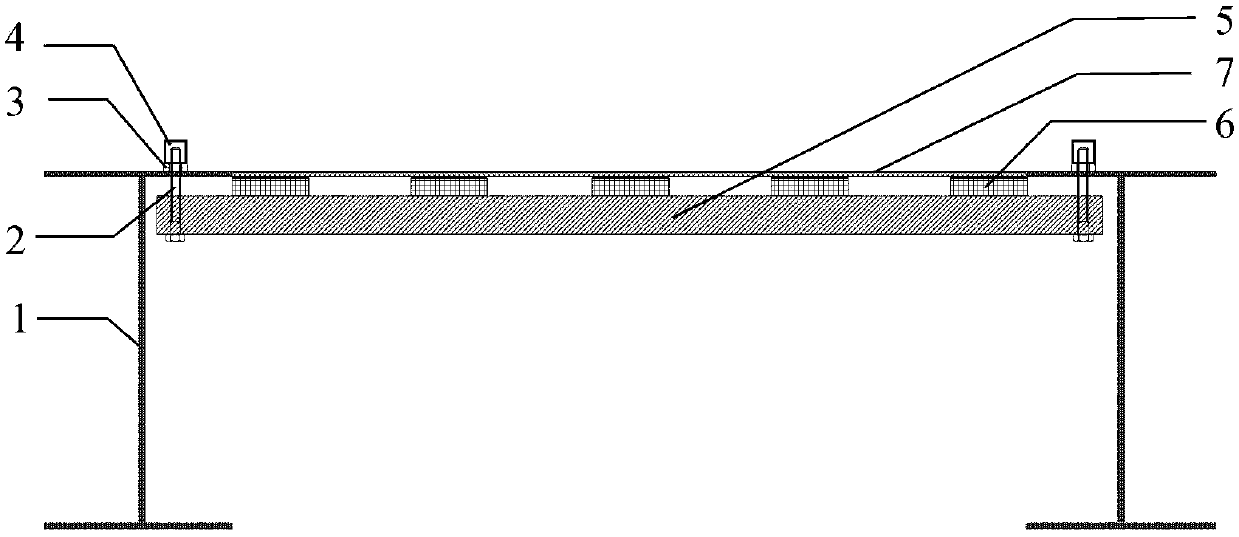

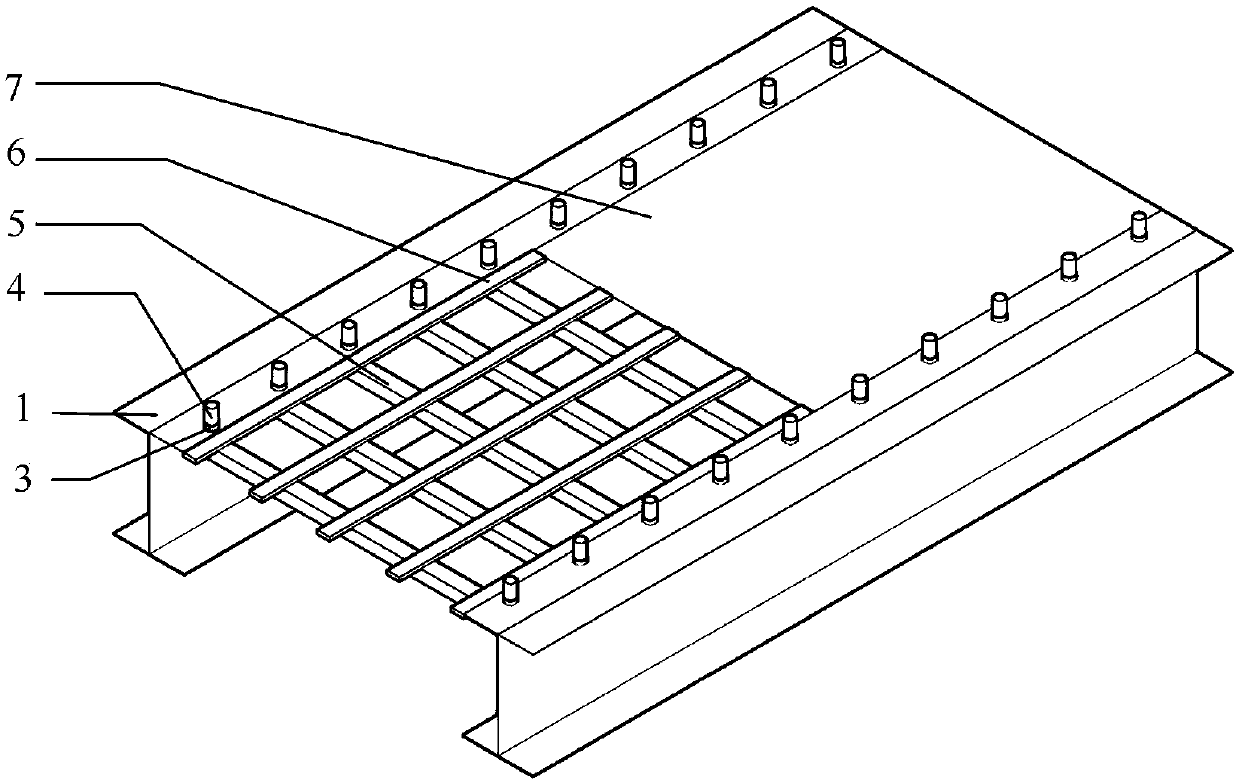

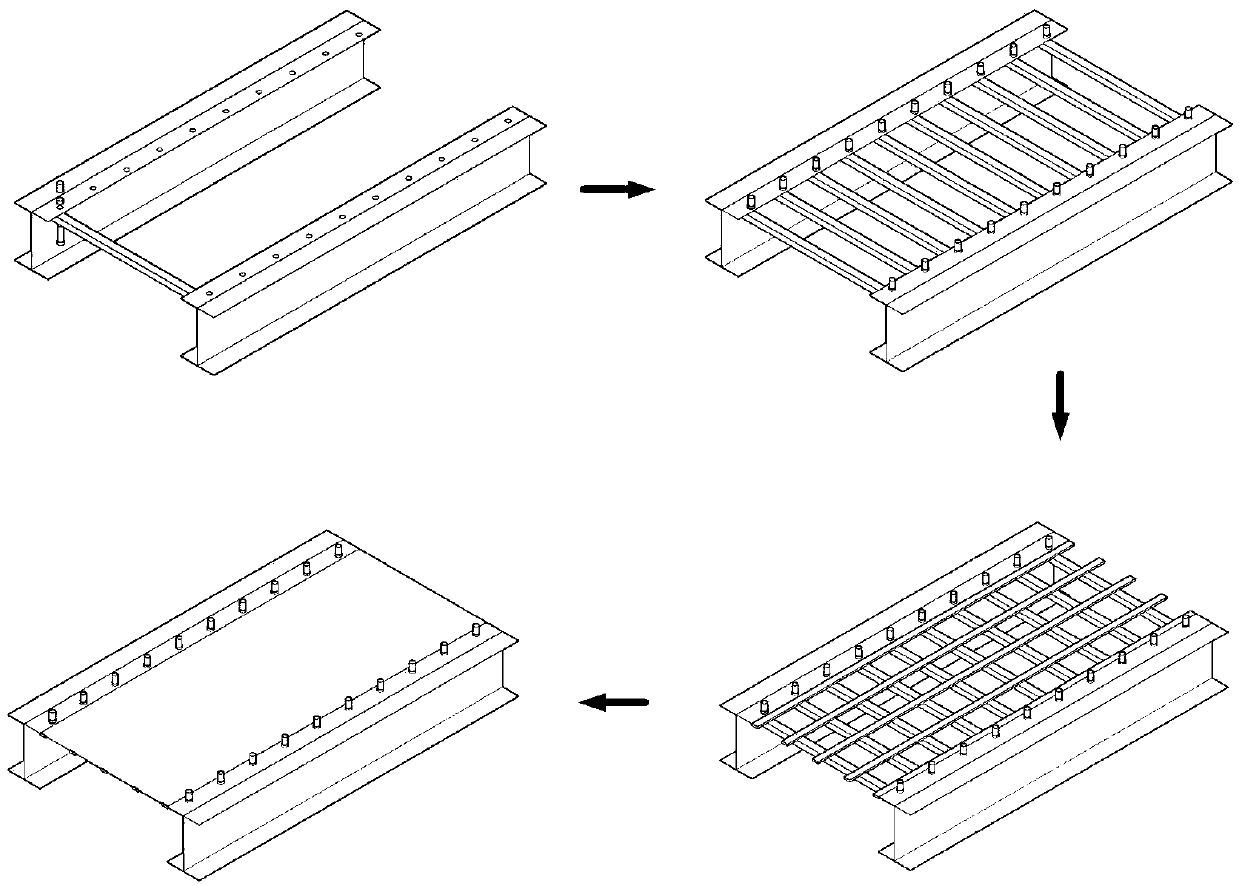

[0020] A high-efficiency steel-concrete composite girder deck formwork structure of the present invention is provided with reserved holes during processing of the I-shaped steel beam, and the composite formwork structure is fixed on the I-shaped steel beam through high-strength bolts and nuts, wherein the composite formwork structure includes Square steel pipe, square wood and clear water formwork, using plastic sleeves to isolate concrete and high-strength bolts. The formwork structure can be applied to the paving process of the I-beam-concrete composite girder deck.

[0021] figure 1 , figure 2 with image 3 It is a specific implementation example of the construction and usage of a high-efficiency I-beam-concrete composite girder bridge deck formwork, such as figure 1 with figure 2 As shown, the construction method is mainly composed of I-shaped steel beam 1, high-strength bolt 2, nut 3, plastic sleeve 4, square steel pipe 5, square wood 6, and clear water formwork 7. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com