Prefabricated road board connected with bolt with one end bent back as well as production method and connection technologyof prefabricated road board

A technology of elbow bolts and manufacturing methods, which is applied in the field of prefabricated road slabs connected by elbow bolts and its manufacturing field, can solve the problems of non-compliance with sustainable development of green construction, adverse effects of construction period, long construction time, etc., and achieve reduction Hidden dangers in quality, high construction efficiency, and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

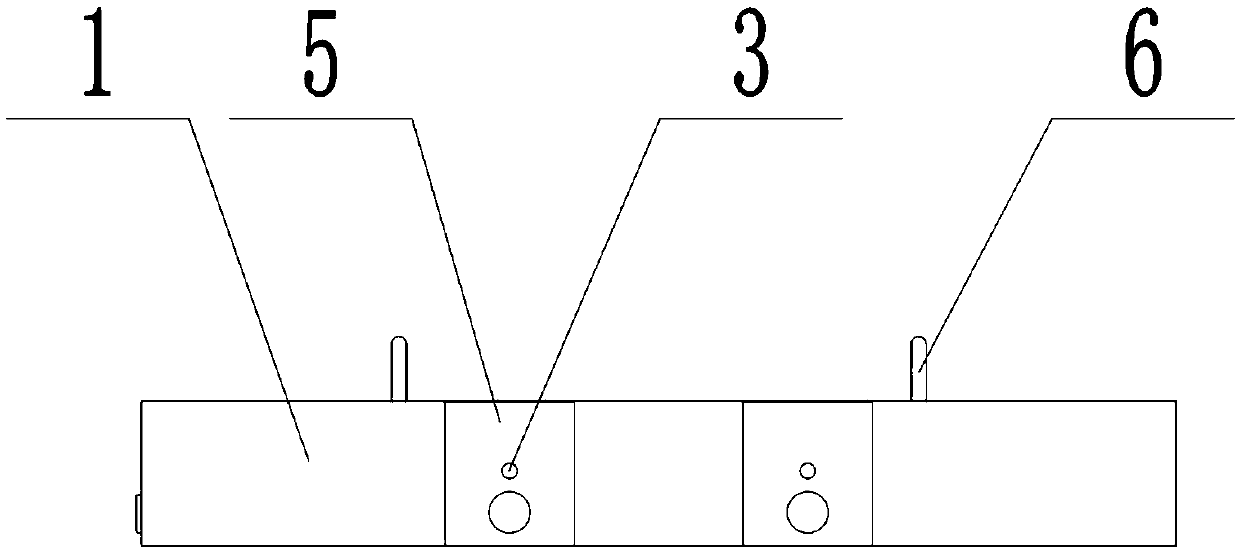

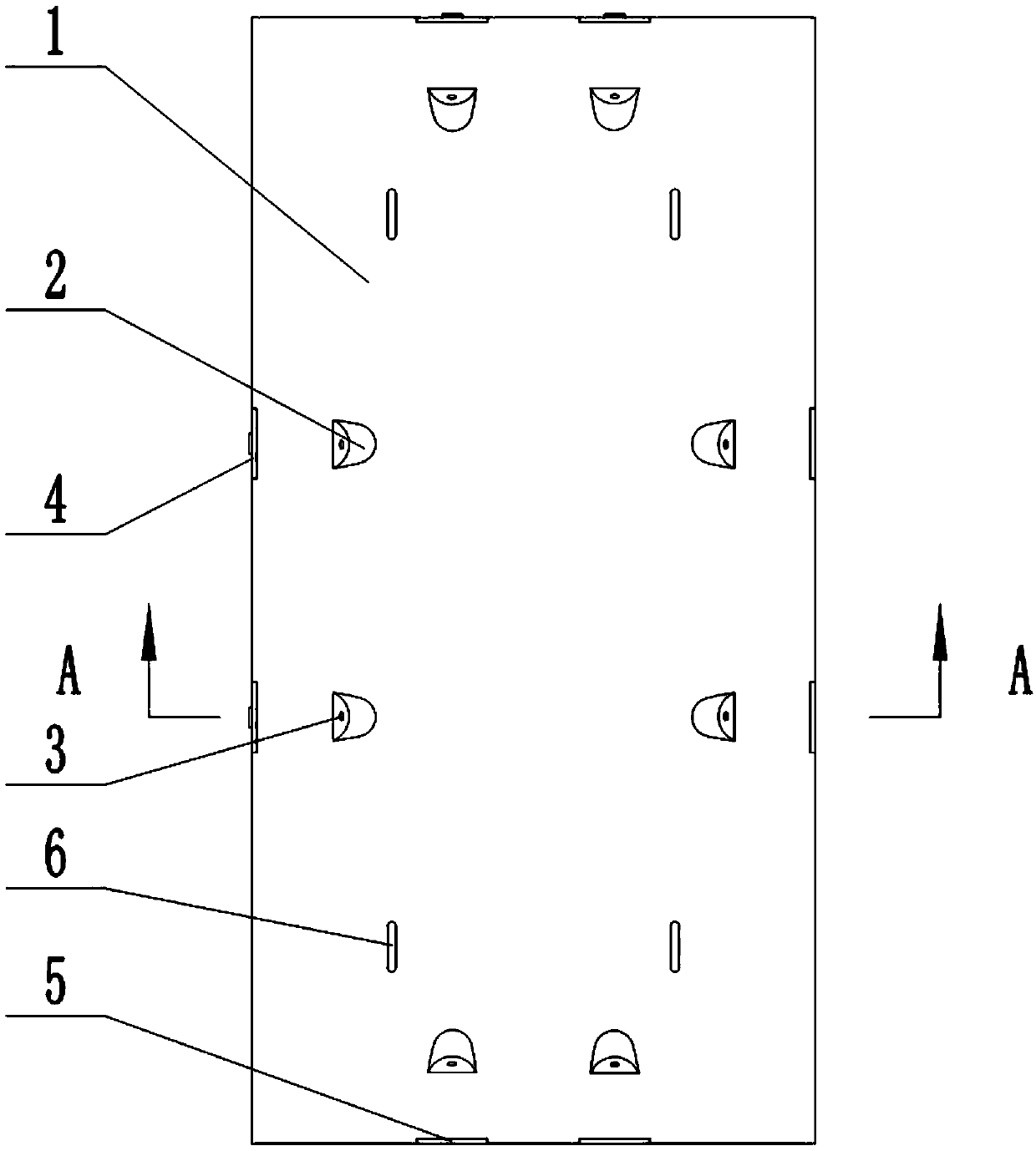

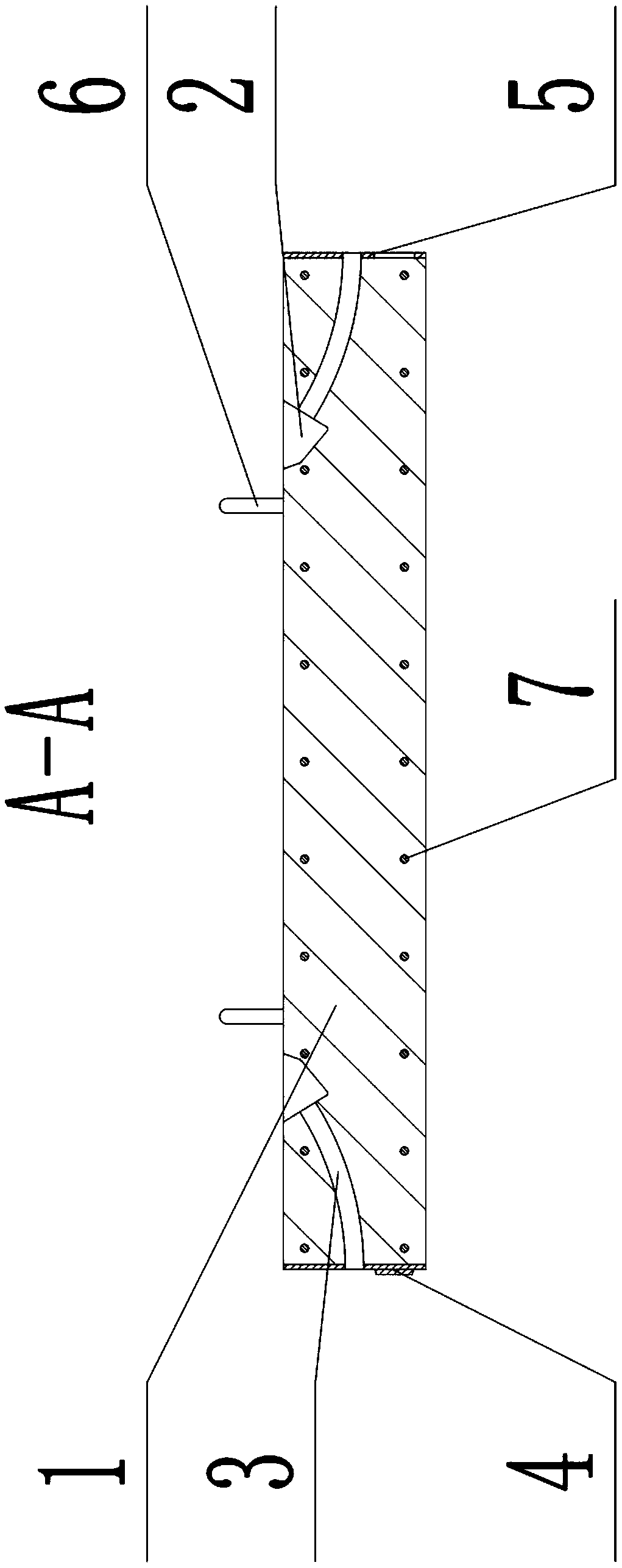

[0067] A prefabricated road slab connected by elbow bolts, comprising a flat cuboid road slab body 1 with a plurality of horseshoe grooves 2 on the top of the road slab body 1, and a plurality of arcs for the elbow connecting bolts to pass through. The two ends of the arc-shaped hole 3 and the arc-shaped hole 3 are respectively connected with the side wall of the road plate main body 1 and the horseshoe groove 2. The two adjacent sides of the road plate main body 1 are fixed with convex iron plates 4, and the other side of the road plate main body 1 Two adjacent sides are provided with concave iron plates 5. The convex iron plates 4 and concave iron plates 5 are both located at the arc-shaped holes 3 on the side walls of the road plate main body 1. The convex iron plates 4 and concave iron plates 5 are both provided There are through holes matching the arc-shaped holes 3, the convex iron plate 4 is provided with bumps, the concave iron plate 5 is provided with grooves matching t...

Embodiment 2

[0092] A prefabricated road slab connected by elbow bolts, comprising a flat cuboid road slab body 1 with a plurality of horseshoe grooves 2 on the top of the road slab body 1, and a plurality of arcs for the elbow connecting bolts to pass through. The two ends of the arc-shaped hole 3 and the arc-shaped hole 3 are respectively connected with the side wall of the road plate main body 1 and the horseshoe groove 2. The two adjacent sides of the road plate main body 1 are fixed with convex iron plates 4, and the other side of the road plate main body 1 Two adjacent sides are provided with concave iron plates 5. The convex iron plates 4 and concave iron plates 5 are both located at the arc-shaped holes 3 on the side walls of the road plate main body 1. The convex iron plates 4 and concave iron plates 5 are both provided There are through holes matching the arc-shaped holes 3, the convex iron plate 4 is provided with bumps, the concave iron plate 5 is provided with grooves matching t...

Embodiment 3

[0117] A prefabricated road slab connected by elbow bolts, comprising a flat cuboid road slab body 1 with a plurality of horseshoe grooves 2 on the top of the road slab body 1, and a plurality of arcs for the elbow connecting bolts to pass through. The two ends of the arc-shaped hole 3 and the arc-shaped hole 3 are respectively connected with the side wall of the road plate main body 1 and the horseshoe groove 2. The two adjacent sides of the road plate main body 1 are fixed with convex iron plates 4, and the other side of the road plate main body 1 Two adjacent sides are provided with concave iron plates 5. The convex iron plates 4 and concave iron plates 5 are both located at the arc-shaped holes 3 on the side walls of the road plate main body 1. The convex iron plates 4 and concave iron plates 5 are both provided There are through holes matching the arc-shaped holes 3, the convex iron plate 4 is provided with bumps, the concave iron plate 5 is provided with grooves matching t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com