Polyethylene acetate cotton ground mat fitting Chinese art paper transfer printing process

A polyvinyl acetate and floor mat technology, applied in carpets, coatings, applications, etc., can solve the problems of incapable of high-quality use of consumers, the easy aging of pure EVA/PVC materials, and the cumbersome production process. The effect is more perfect, the pattern effect is obvious, the color effect is rich

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

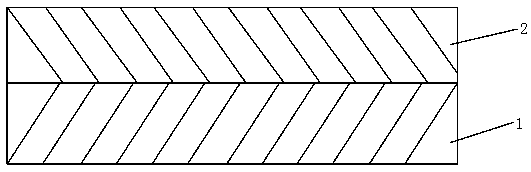

Image

Examples

Embodiment 1

[0027] Embodiment 1: The present invention is a pad printing process of a polyvinyl acetate cotton floor mat laminated with rice paper, comprising the following process steps:

[0028] S1: EVA anti-slip layer 1 is plasticized, and the EVA anti-slip layer 1 includes the following components: 50 parts of PEVA, 20 parts of dioctyl terephthalate, 2 parts of stabilizer (the stabilizer is an organotin heat stabilizer), 0.001 part of PVC color masterbatch, 3 parts of epoxy soybean oil, mix the raw materials of the above components, stir at high speed, and plasticize through the internal mixer;

[0029] S2: EVA anti-slip layer 1 is formed by heating with a planetary extrusion device;

[0030] S3: low tension rice paper transfer printing;

[0031] S4: flocking, the fluff is attracted by the EVA anti-slip layer 1 with different potential, and accelerates to fly vertically to the surface of the EVA anti-slip layer 1, ensuring that the fluff sticks vertically to the EVA anti-slip layer 1...

Embodiment 2

[0040] Embodiment two: the present invention is a kind of pad printing process of polyvinyl acetate cotton floor mat laminating rice paper, comprising the following process steps:

[0041] S1: EVA anti-slip layer 1 is plasticized, and the EVA anti-slip layer 1 includes the following components: 95 parts of PEVA resin powder, 60 parts of dioctyl terephthalate, 3 parts of stabilizer (the stabilizer is organotin thermally stable agent), 1.5 parts of PVC color masterbatch, 4 parts of epoxy soybean oil, mix the raw materials of the above components, stir at high speed, and plasticize through the internal mixer;

[0042] S2: EVA anti-slip layer 1 is formed by heating with a planetary extrusion device;

[0043] S3: low tension rice paper transfer printing;

[0044] S4: flocking, the fluff is attracted by the EVA anti-slip layer 1 with different potential, and accelerates to fly vertically to the surface of the EVA anti-slip layer 1, ensuring that the fluff sticks vertically to the E...

Embodiment 3

[0053]Embodiment 3: The present invention is a pad printing process for laminating a polyethylene acetate cotton floor mat with rice paper, comprising the following process steps:

[0054] S1: EVA anti-slip layer 1 is plasticized, and the EVA anti-slip layer 1 includes the following components: 80 parts of PEVA resin powder, 55 parts of dioctyl terephthalate, 2.5 parts of stabilizer (the stabilizer is organotin thermally stable agent), 1.0 parts of PVC color masterbatch, 3.2 parts of epoxy soybean oil, mix the raw materials of the above components, stir at high speed, and plasticize through the internal mixer;

[0055] S2: EVA anti-slip layer 1 is formed by heating with a planetary extrusion device;

[0056] S3: low tension rice paper transfer printing;

[0057] S4: flocking, the fluff is attracted by the EVA anti-slip layer 1 with different potential, and accelerates to fly vertically to the surface of the EVA anti-slip layer 1, ensuring that the fluff sticks vertically to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com