Heat-resistant silicone protective film

A protective film and heat-resistant technology, applied in the field of film materials, can solve problems such as degumming and deformation, and achieve the effects of uniform heating, enhanced heat resistance, and easy conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] A heat-resistant silica gel protective film includes a carrier layer and a silica gel layer.

[0026] The carrier layer includes a polyimide layer. In embodiments where there is no transparency requirement, the carrier layer may be composed of a single polyimide layer. In some embodiments, the carrier layer also includes an anti-PET layer. , One or more of electrostatic layer, thermal conductive layer and conductive layer, polyimide layer, antistatic layer, thermal conductive layer or conductive layer can be coated on the polyimide layer by coating, The thickness of the carrier layer is 35-75um.

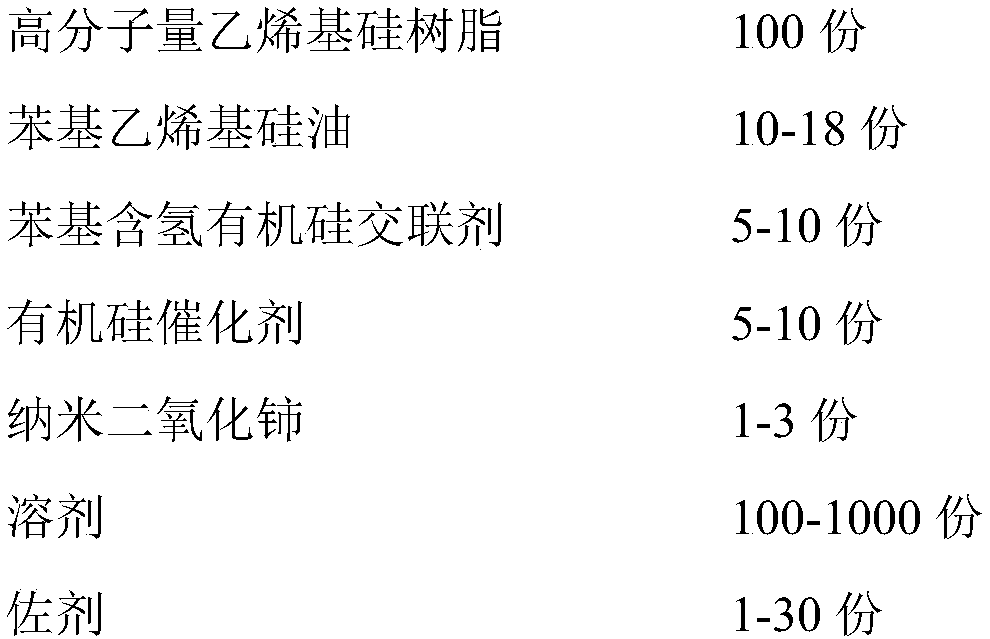

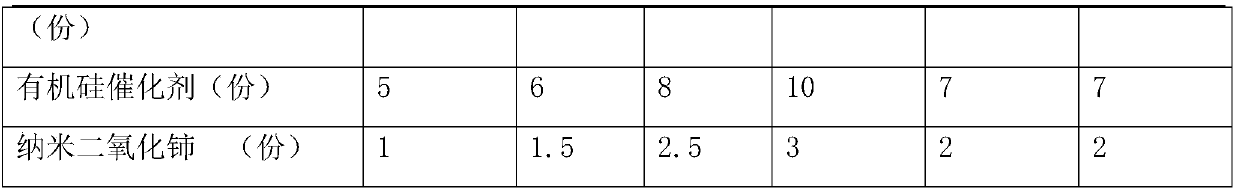

[0027] The silica gel layer includes high molecular weight vinyl silicone resin, phenyl vinyl silicone oil, phenyl hydrogen-containing silicone crosslinking agent, silicone catalyst, nano ceria, solvent and adjuvant, and the thickness of the silica gel layer is 50-150um. In actual production, the thickness of the silica gel layer is generally 25-45um. In this thickness range, both...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com