Dimethicone preparation method

A technology of dimethicone and polydimethylsiloxane is applied in the field of preparation of high-purity dimethicone, which can solve the problems of ineffective solid acid, decrease in purity, complicated preparation steps, etc., and achieve the amount of waste acid produced in wastewater. Less, the preparation method is simple, the effect of simple reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of simethicone oil, comprising the steps of:

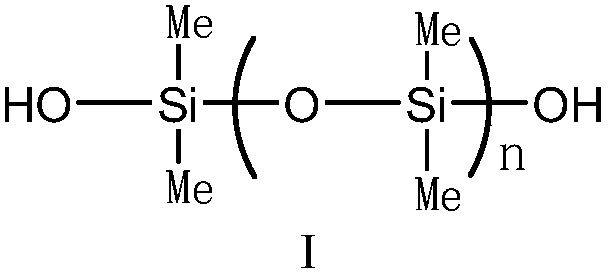

[0036](1) The preparation method of the polydimethylsiloxane of hydroxyl termination is as follows: Dimethyldichlorosilane is under the concentrated hydrochloric acid catalysis of 35% in mass concentration (the mass ratio of dimethyldichlorosilane and 35wt% concentrated hydrochloric acid 3:1), hydrolysis reaction was carried out at -5°C for 0.5h to obtain a hydrolyzate; the hydrolyzate was washed to neutrality, and then the cyclosiloxane in the hydrolyzate was evaporated to obtain a linear body, namely hydroxyl-terminated polydimethyl Silicone (Hydroxysilicone). Characterize the obtained hydroxyl-terminated polydimethylsiloxane: In the structural formula of formula I, n=30; heat at 150° C. for 3 hours, and the mass of the volatile matter is 0.8% of the mass of the obtained hydroxyl-terminated polydimethylsiloxane .

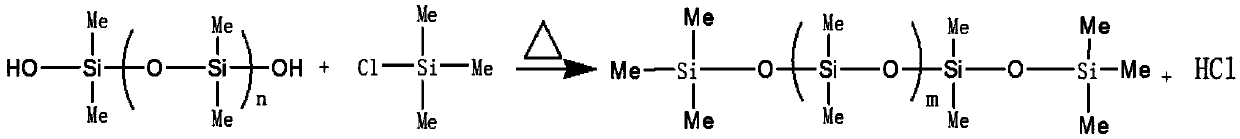

[0037] (2) Take the above-mentioned hydroxyl-terminated polydimethylsiloxane, raise t...

Embodiment 2

[0040] A preparation method of simethicone oil, comprising the steps of:

[0041] (1) The hydroxyl-terminated polydimethylsiloxane is commercially available, available from Dow Corning Company, the model is PMX-0156; the hydroxyl-terminated polydimethylsiloxane is characterized: in the formula I structural formula, n= 66; heating at 150° C. for 3 hours, the mass of the volatile matter is 0.2% of the mass of the obtained hydroxyl-terminated polydimethylsiloxane.

[0042] (2) Take the above-mentioned hydroxyl-terminated polydimethylsiloxane, raise the temperature to 150°C, bubble nitrogen, vacuumize for 2 hours, and keep the vacuum at -0.09MPa to obtain the pretreated hydroxyl-terminated polydimethylsiloxane alkane; cool the pretreated hydroxyl-terminated polydimethylsiloxane to 70°C, and then add trimethylchlorosilane to the reaction kettle according to the mass ratio of 10:1, mix well, control the temperature at 70°C, and the pressure 0.1MPa, stirring and pressurizing for 6 h...

Embodiment 3

[0045] A preparation method of simethicone oil, comprising the steps of:

[0046] (1) Hydroxyl-terminated polydimethylsiloxane is commercially available, and is available from Shandong Dongyue Organic Silicon Material Co., Ltd.; characterize the hydroxyl-terminated polydimethylsiloxane: In the structural formula of formula I, n =100; heating at 150° C. for 3 hours, the mass of the volatile matter is 0.6% of the mass of the obtained hydroxyl-terminated polydimethylsiloxane.

[0047] (2) Take the above-mentioned hydroxyl-terminated polydimethylsiloxane, raise the temperature to 140°C, bubble nitrogen, vacuumize for 1.5h, and keep the vacuum at -0.090MPa to obtain the pretreated hydroxyl-terminated polydimethylsiloxane Oxane; cool the pretreated hydroxyl-terminated polydimethylsiloxane to 75°C, and then add trimethylchlorosilane to the reactor in a mass ratio of 10:2, mix well, and control the temperature to 75°C. Pressure 1MPa, stirring and pressurizing for 4 hours; release the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com