Preparation method of luminous anti-skid glass

A glass, anti-skid technology, applied in glass manufacturing equipment, glass tempering, manufacturing tools, etc., can solve the problems of easy falling, loss of transparency, complicated preparation process, etc., and achieve the effect of preventing pedestrians from falling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

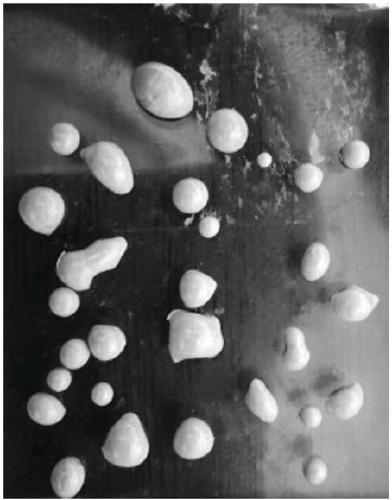

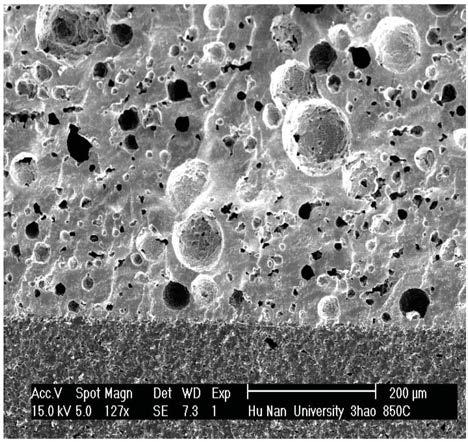

Image

Examples

preparation example Construction

[0033] The invention provides a preparation method of luminous anti-skid glass, the preparation method comprising the following steps:

[0034] Step 1. Surface treatment of luminous powder:

[0035] Eu-doped Sr with a diameter of 100-150 μm 2 o 4 Base luminous powder, soaked in acetone solution, ultrasonic cleaning at 4000HZ frequency for 20-30 minutes;

[0036] After filtering out the luminous powder, put it at room temperature for 2-3 hours, then soak it in a dilute sulfuric acid solution with a concentration of 1wt% for 4-6 minutes, then filter out the luminous powder, rinse the luminous powder with deionized water, and wash it away When the ionized water becomes neutral, stop flushing;

[0037] Put the rinsed luminous powder in an oven at 60°C and dry it for 12 hours to obtain a cleaned luminous powder;

[0038] In step one, specifically, commercially available Eu-doped Sr with a diameter of 100-150 μm 2 o 4 Base luminous powder, in the transportation link after prod...

Embodiment 1

[0058] The invention provides a preparation method of luminous anti-skid glass, the preparation method comprising the following steps:

[0059] Step 1. Surface treatment of luminous powder:

[0060] Eu-doped Sr with a diameter of 100 μm 2 o 4 Base luminous powder, soaked in acetone solution, ultrasonic cleaning at 4000HZ frequency for 20 minutes;

[0061] After filtering out the luminous powder, place it at room temperature for 2 hours, then soak it in a dilute sulfuric acid solution with a concentration of 1wt% for 5 minutes, then filter out the luminous powder, rinse the luminous powder with deionized water, and when the deionized water becomes When neutral, stop flushing;

[0062] Put the rinsed luminous powder in an oven at 60°C and dry it for 12 hours to obtain a cleaned luminous powder;

[0063] Step 2. Surface improvement of luminous powder:

[0064] ZrOCl 2 Dissolved in deionized water to prepare ZrOCl with a concentration of 2mol / L 2 solution, and then under th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com