Antibacterial hydrogel dressing containing imidazolium bromide and preparation method and application of antibacterial hydrogel dressing

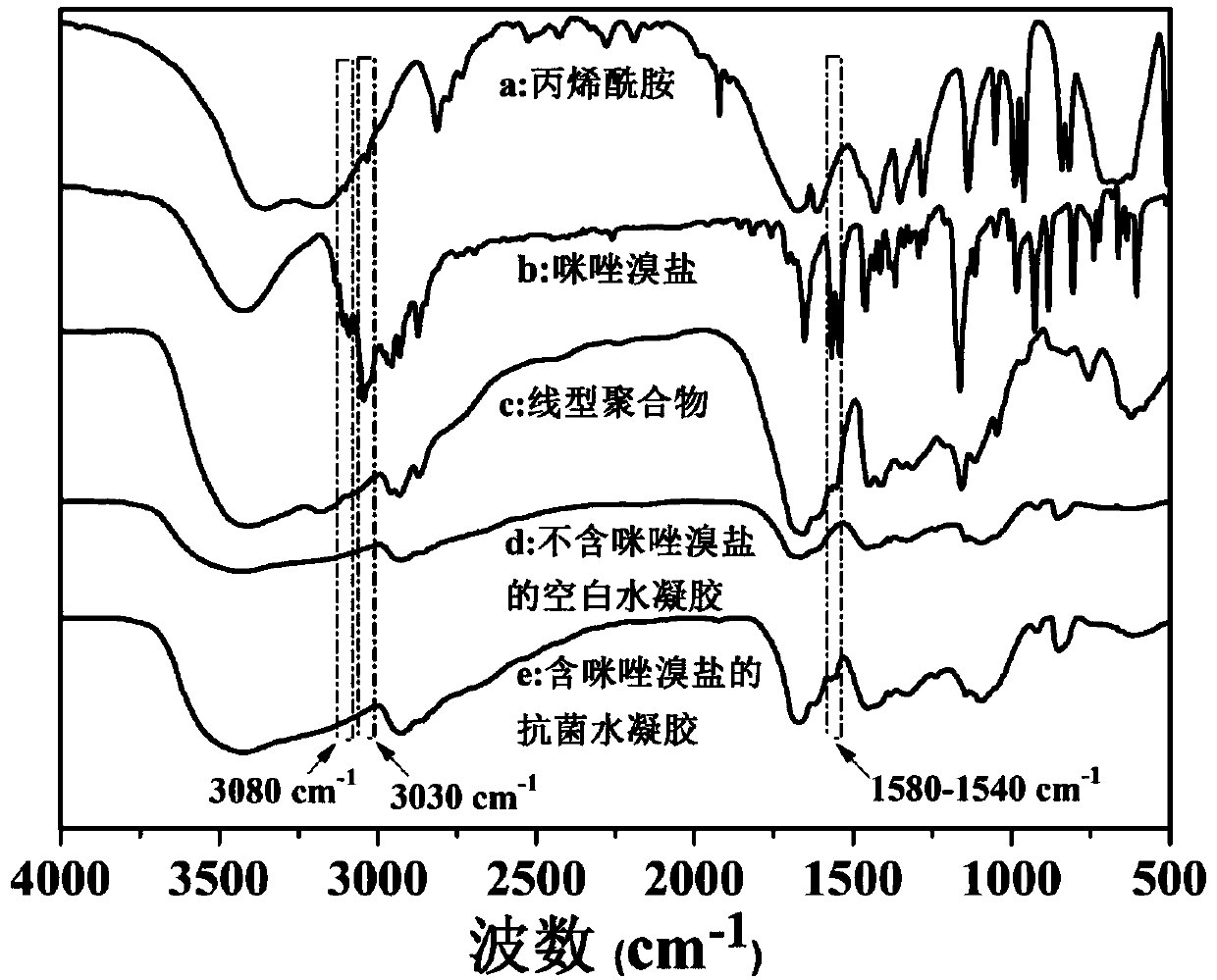

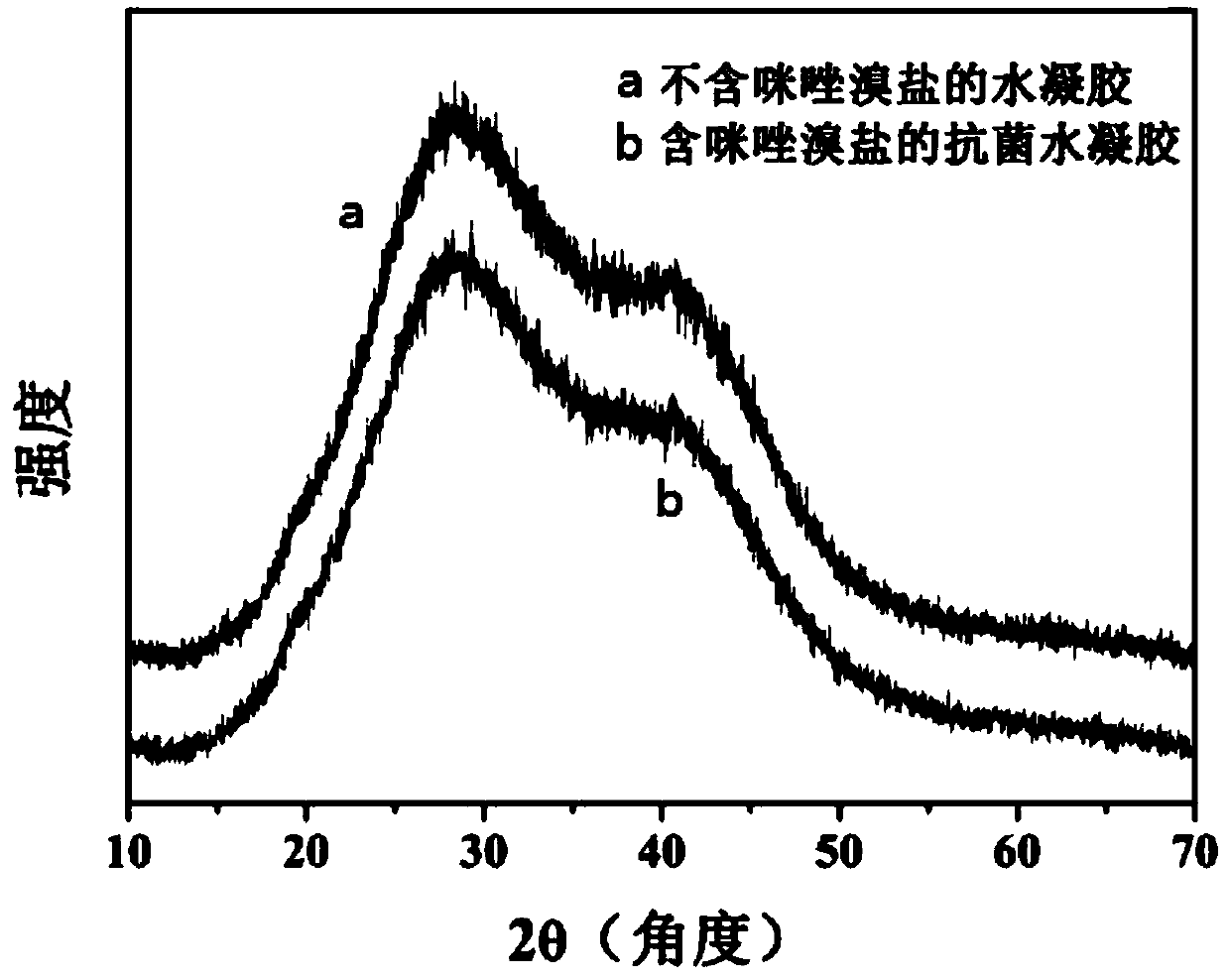

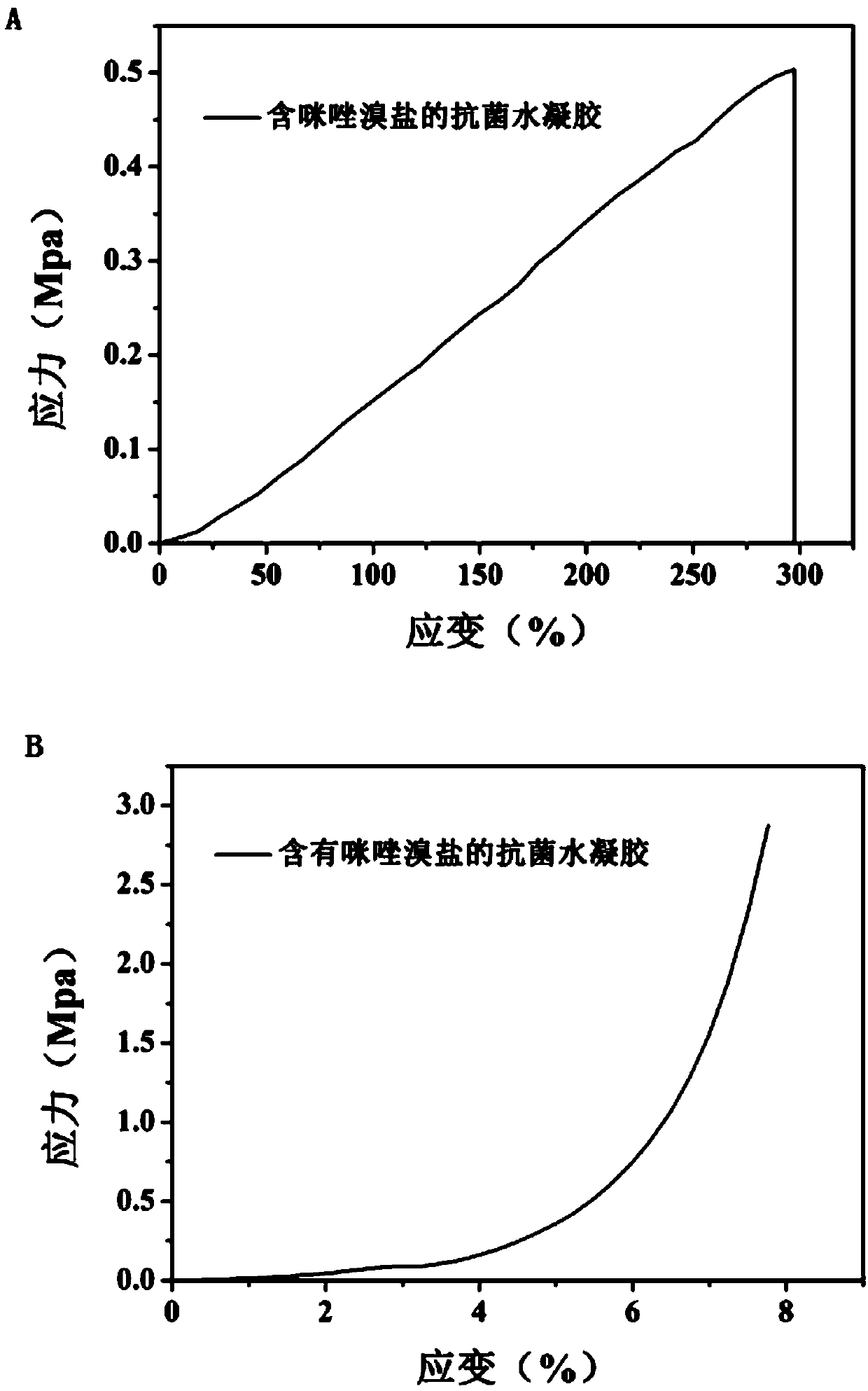

An antibacterial water and hydrogel technology, applied in the fields of polymer materials and biological materials, can solve the problems of single hydrogel performance and no antibacterial function, and achieve good biocompatibility and antibacterial performance, good bactericidal activity, Experiment with simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Weigh 10g of polyvinyl alcohol (PVA), pour it into a three-necked flask, add 90ml of distilled water, take a constant temperature water bath at 100°C for 3 hours, stir at high speed to dissolve the PVA, and obtain a 10% PVA solution;

[0039] (2) 5g of acrylamide was added to 15mL of deionized water, then 0.2g of initiator ammonium persulfate was added, and nitrogen gas was introduced for 5 minutes to remove oxygen in the solution and prevent the chemical substances in the reaction solution from reacting with oxygen to obtain a mixed solution;

[0040] (3) Take 25g of 10% PVA solution, add 20g of the mixed solution in step (2), stir evenly, and then use an ultrasonic instrument to sonicate for 30min at 45HZ;

[0041] (4) The mixed solution of step (3) was heated at 70° C. for 30 minutes;

[0042] (5) The solution in (4) was subjected to cyclic freezing-thawing, specifically: freezing at -20°C for 12 hours and thawing at 20°C for 3 hours. The freezing-thawing process...

Embodiment 2

[0044] (1) Weigh 10g of PVA, pour it into a three-necked flask, add 90ml of distilled water, take a constant temperature water bath at 100°C for 3 hours, stir at a high speed to dissolve the PVA, and obtain a 10% PVA solution;

[0045] (2) Add 5g of acrylamide and 5g of 1-vinyl-3-butylimidazolium bromide into 15mL of deionized water, then add 0.2g of initiator ammonium persulfate, and pass nitrogen gas for 5 minutes to remove oxygen in the solution and prevent the reaction liquid from The chemical substance in the medium reacts with oxygen to obtain a mixed solution;

[0046] (3) Take 50 g of 10% PVA solution, add 12.3 g of the mixed solution in step (2), stir evenly, and then use an ultrasonic instrument to sonicate for 30 min at 45 Hz;

[0047] (4) The mixed solution of step (3) was heated at 70° C. for 30 minutes;

[0048] (5) The solution of (4) is subjected to cycle freezing-thawing, freezing at -20°C for 12h, and thawing at 20°C for 3h, the freezing-thawing process is rep...

Embodiment 3

[0051] (1) Weigh 10g of PVA, pour it into a three-necked flask, add 90ml of distilled water, take a constant temperature water bath at 100°C for 3 hours, stir at a high speed to dissolve the PVA, and obtain a 10% PVA solution;

[0052] (2) Add 5g of acrylamide and 5g of 1-vinyl-3-butylimidazolium bromide into 15mL of deionized water, then add 0.2g of initiator ammonium persulfate, and pass nitrogen gas for 5min to obtain a mixed solution;

[0053] (3) Take 50 g of 10% PVA solution, add 6.5 g of the mixed solution in step (2), and stir evenly. Then, sonicate for 30 minutes under the condition of 45HZ with an ultrasonic instrument.

[0054] (4) The mixed solution of step (3) was heated at 70° C. for 30 minutes;

[0055] (5) The solution of (4) is subjected to cycle freezing-thawing, freezing at -20°C for 12h, and thawing at 20°C for 3h, the freezing-thawing process is repeated 6 times to obtain an antibacterial hydrogel dressing containing imidazolium bromide .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com