Cocktail method bi-color freeze-dried powder and preparation method thereof

A technology of freeze-dried powder and cocktail, which is applied in the direction of pharmaceutical formulations, cosmetic preparations, dressing preparations, etc., which can solve the problems of incomplete effects, increased dosage of excipients, poor vision, etc., so that it is not easy to interact, suitable For long-term storage, the effect of long storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

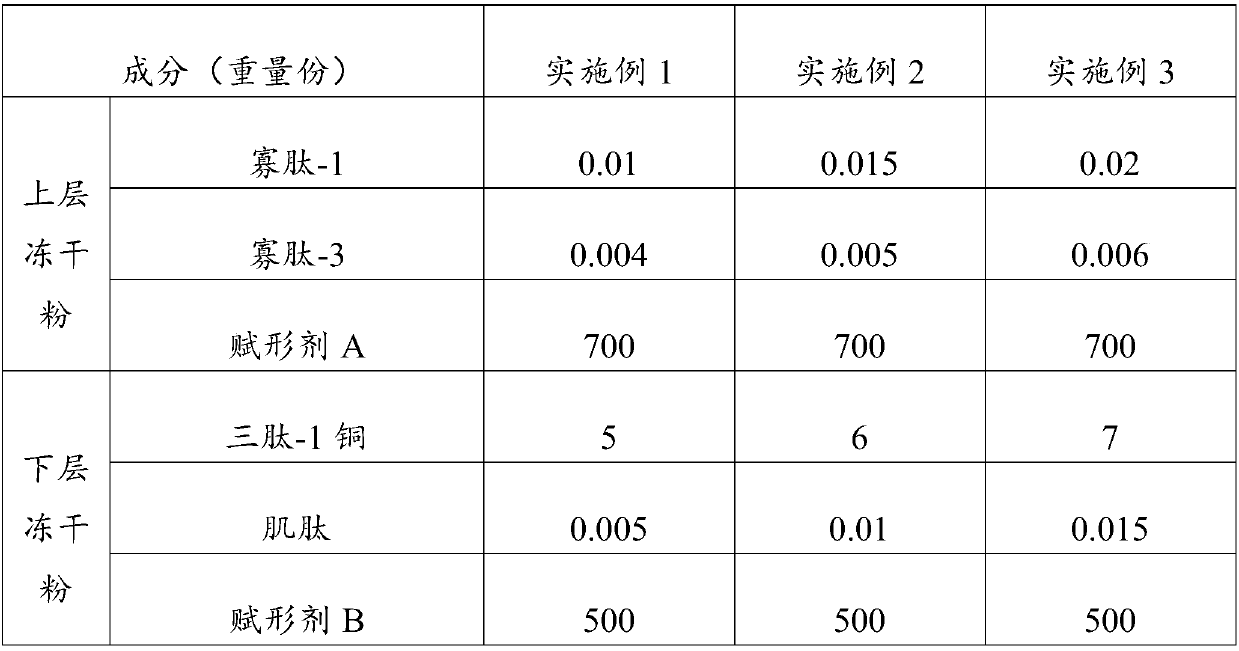

Embodiment 1~3

[0031] See Table 1 for the raw material formula of the cocktail method double-color freeze-dried powder described in Examples 1-3, see Table 2 for the raw material formula of excipient A, and see Table 3 for the raw material formula of excipient B.

[0032] The preparation method of the cocktail method double-color freeze-dried powder described in Examples 1-3 comprises the following steps:

[0033] (1), the raw materials of the upper layer freeze-dried powder and the lower layer freeze-dried powder are respectively prepared into an upper layer freeze-dried powder solution and a lower layer freeze-dried powder solution;

[0034] (2), the lower layer of freeze-dried powder solution is first injected into the packaging bottle, and then the upper layer of freeze-dried powder solution is injected into the packaging bottle for freeze-drying treatment:

[0035] a. Lower the temperature to -44°C and keep it for 10 minutes;

[0036] b. Heat up to -35°C within 20 minutes, and keep at ...

Embodiment 4

[0053] The freeze-dried powders prepared in Examples 1-3 and Comparative Example were placed for 0, 6 months and 12 months respectively, dissolved in water, and the time required for complete dissolution was tested. The test results are shown in Table 4.

[0054] The dissolving time of the lyophilized powder that table 4 embodiment 1~3 and comparative example make

[0055]

[0056] As can be seen from the results in Table 4, the freeze-dried powder described in Examples 1 to 3 can still be dissolved in water quickly after being placed for 12 months, while the freeze-dried powder described in Comparative Example needs to be dissolved in water after being placed for 12 months. It takes a long time to completely dissolve, indicating that the formula of the two-color freeze-dried powder of the present invention is more stable and can be stored for a long time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com