Artemisia integrifolia composite powder, preparation method and application thereof in flour products

A technology of artemisia sagebrush and compound powder is applied in the field of compound powder and its preparation, which can solve the problems of not being able to make full use of various nutritional values, not rich in nutritional types, and low in nutritional value, so as to achieve rich nutritional types, high physiological value, and low nutritional value. high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation steps of a kind of Artemisia annua bud composite powder of the present invention are as follows: take fresh main raw materials, peel them, clean them, put them in a drying box, and control the temperature in the drying box to be 80° C. by energizing heating, and hold for 1 hour. Turn off the power supply, cool at a constant temperature for 30 minutes to discharge the water vapor to obtain dry raw materials; send the dried raw materials into the ultrafine pulverizer from the feed port, set the minimum pressure to 0Mpa, and the maximum value to 1.8Mpa The lowest temperature is -20°C, and the highest is 30°C. Open the control valve to start pulverization, so that the ultrafine pulverizer works in a cycle under this airflow condition, and pulverize the dried raw materials into powder to prepare the main ingredient.

[0041] Take fresh raw materials of auxiliary materials, peel them, clean them, put them into a drying box, turn on the electricity to heat and c...

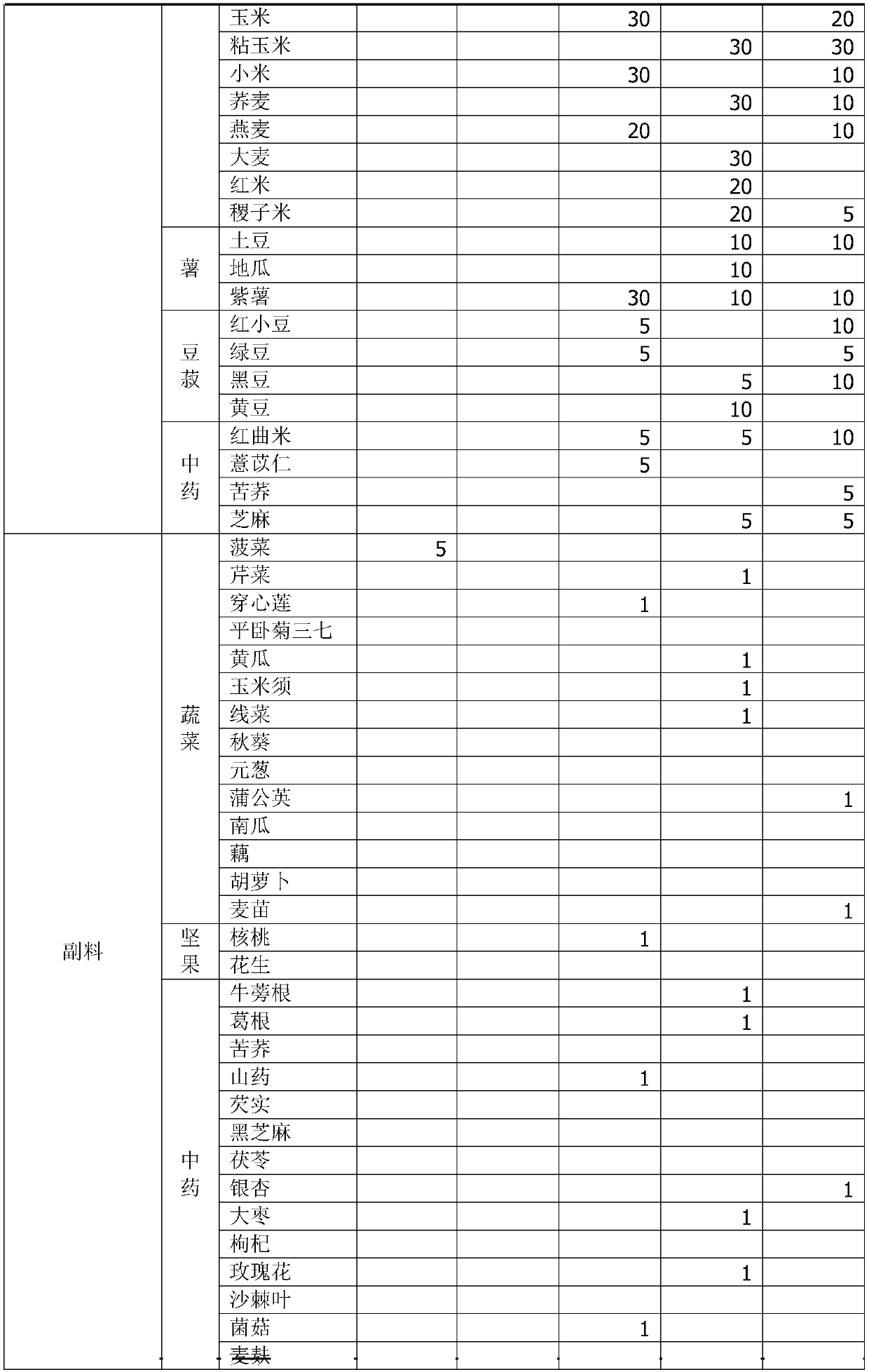

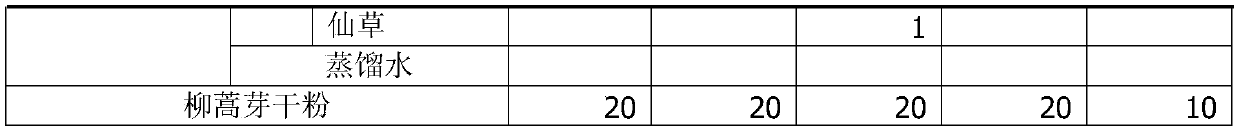

Embodiment 3

[0054] Embodiment 3: described major ingredient is made of 200g flour, 100g rice flour, 20g black rice flour, 50g glutinous rice flour, 30g corn flour, 30g millet flour, 20g oat flour, 30g purple sweet potato flour, 5g red bean flour, 5g mung bean flour, 5g of red yeast rice flour and 5g of coix seed powder are mixed and prepared; the auxiliary material is prepared by mixing 1g of Andrographis paniculata powder, 1g of walnut powder, 1g of Chinese yam powder, 1g of mushroom powder, and 1g of grass jelly powder; 20g. According to the above ratio, the compound powder of Artemisia annua buds is prepared.

Embodiment 5

[0056] Embodiment 5: described principal ingredient is made of 150g flour, 50g black rice flour, 50g sorghum rice flour, 20g corn flour, 30g sticky corn flour, 10g millet flour, 10g buckwheat flour, 10g oat flour, 5g millet rice flour, 10g potato flour, 10g purple sweet potato powder, 10g red bean powder, 5g mung bean powder, 10g black bean powder, 10g red yeast rice powder, 10g coix seed powder, 5g tartary buckwheat powder, 5g sesame powder; Wheatgrass powder is prepared by mixing 1g of ginkgo powder; the dry powder of Artemisia annua buds is 10g. According to the above ratio, the compound powder of Artemisia annua buds is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com