Ordered ultrathin film electrode as well as preparation method and application thereof

An ultra-thin film and electrode technology, applied in the field of electrochemistry, can solve the problems of low catalyst utilization efficiency, large mass transfer resistance, and unfavorable construction of a three-phase reaction interface, and achieve the effects of easy control and optimization of the structure and mild preparation conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: (deposition of Pd on both sides of Nafion film)

[0041] The Nafion membrane is placed between the two reaction pools, and the H 2 PdCl 4 (3.2mM), alcohol amine (25mM), polyoxyethylene lauryl ether (0.3mM) and ascorbic acid (5mM) mixed solution was added to the two reaction pool. After standing at 25° C. for 4 minutes, the reaction solution was poured out, and the membrane electrode was washed with deionized water.

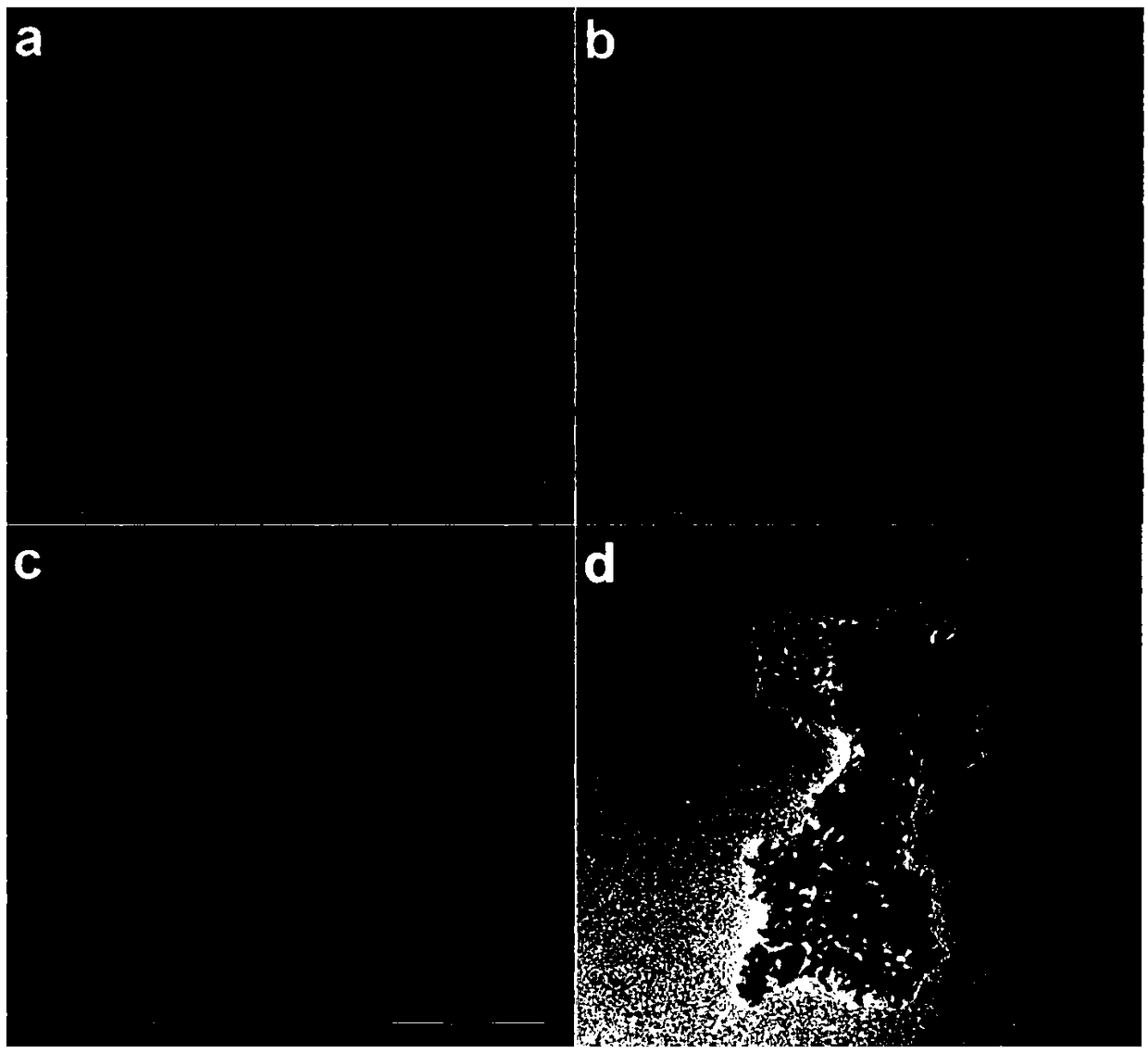

[0042] A black Pd layer is deposited on both sides of the Nafion film. figure 1 It is the SEM and TEM photos of the catalyst layer of the prepared membrane electrode. The catalyst layer on the surface of the SEM photo is dendritic Pd. The Pd part on the Nafion membrane is peeled off by ultrasonic treatment, and the TEM characterization is performed. The TEM photo shows some Pd dendritic fragments, indicating that Each Pd branch is in turn composed of small dendritic structures. The results show that the catalyst layer is composed of a laye...

Embodiment 2

[0043] Example 2: (deposition of Pd@Pt core-shell structure catalyst layer on both sides of Nafion membrane)

[0044] Refer to Example 1 for the preparation process of the multi-level dendritic Pd layer loaded on both sides of the Nafion membrane.

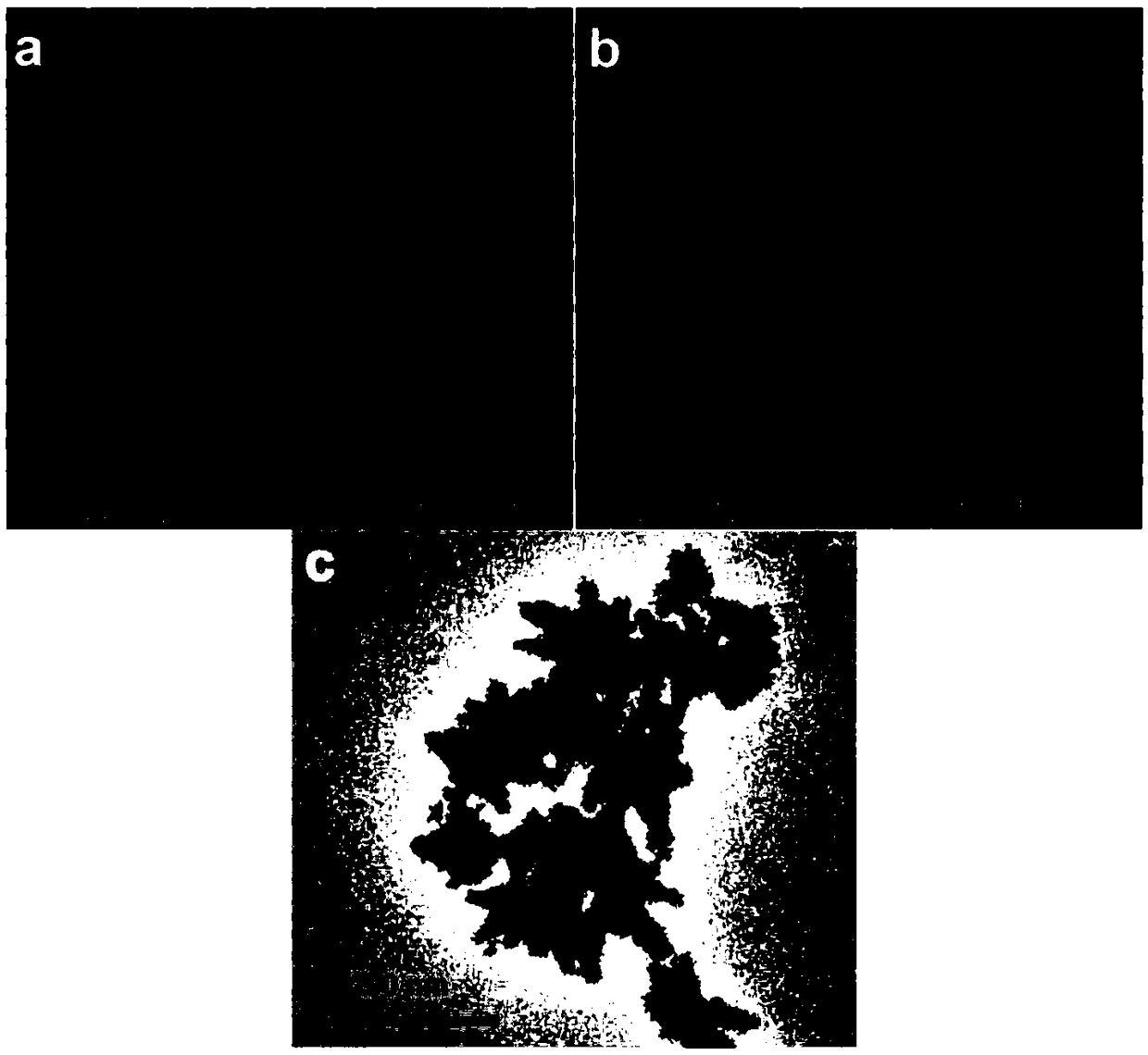

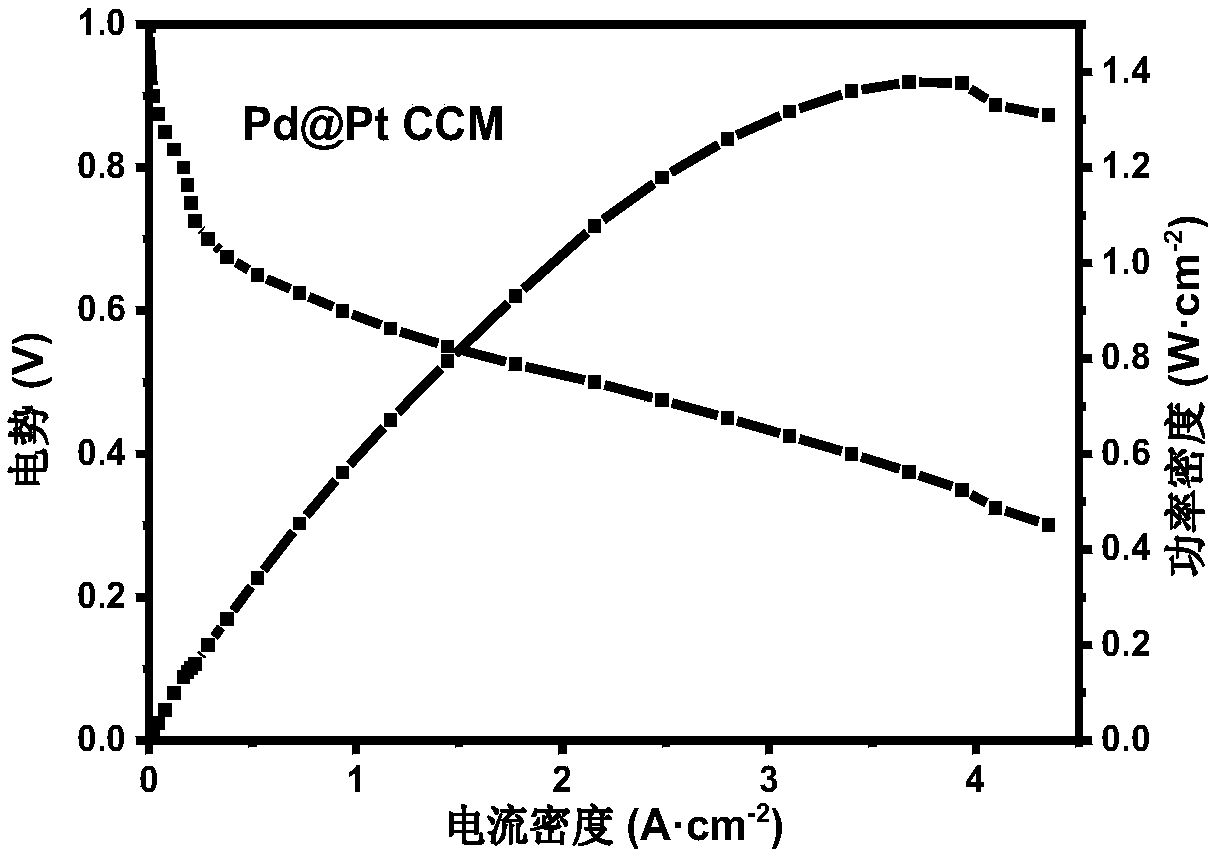

[0045] The Pd@Pt core-shell structure catalyst layer was prepared by loading Pt on the hierarchical dendritic Pd by wet chemical method. Take H 2 PtCl 6 (0.6mM), a mixed solution of sodium dodecylsulfonate (27mM) and ascorbic acid (50mM) was added to the two reaction cells, reacted at 25°C for 7h, poured out the reaction solution, and washed the membrane electrode with deionized water. figure 2 It is an SEM photo of Pt loaded on the hierarchical dendritic Pd, and the results show that the hierarchical dendritic structure remains, and Pt is deposited on the surface of Pd to obtain a catalyst layer with a core-shell structure. The metal loading on both sides of the Nafion membrane is the same, and the ICP test results show that t...

Embodiment 3

[0049] Example 3 (changing the surfactant, preparing a layer of Pd@Pt core-shell catalyst layer on both sides of the Nafion membrane)

[0050] The Nafion membrane is placed between the two reaction pools, and the H 2 PdCl 4 (3.2mM), alcohol amine (25mM), polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (0.06mM) and ascorbic acid (5mM) mixed solution into the two reaction pool. After standing at 25°C for 5 minutes, the reaction solution was poured out, and the membrane electrode was washed with deionized water. Figure 4 The SEM photo of the Pd layer of the membrane electrode prepared for this purpose shows that its structure is slightly different from the use of polyoxyethylene lauryl ether as a structure director, and it is the coexistence of nanoparticles and multi-level dendritic structures.

[0051] The Pd@Pt core-shell catalyst was prepared by loading Pt on the Pd layer by wet chemical method. Take H 2 PtCl 6 (0.6mM), the mixed solution of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com