Rotating machinery fault diagnosis and early warning method

A technology for rotating machinery and fault diagnosis, which is applied in the testing of mechanical components, testing of machine/structural components, and measuring devices. The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

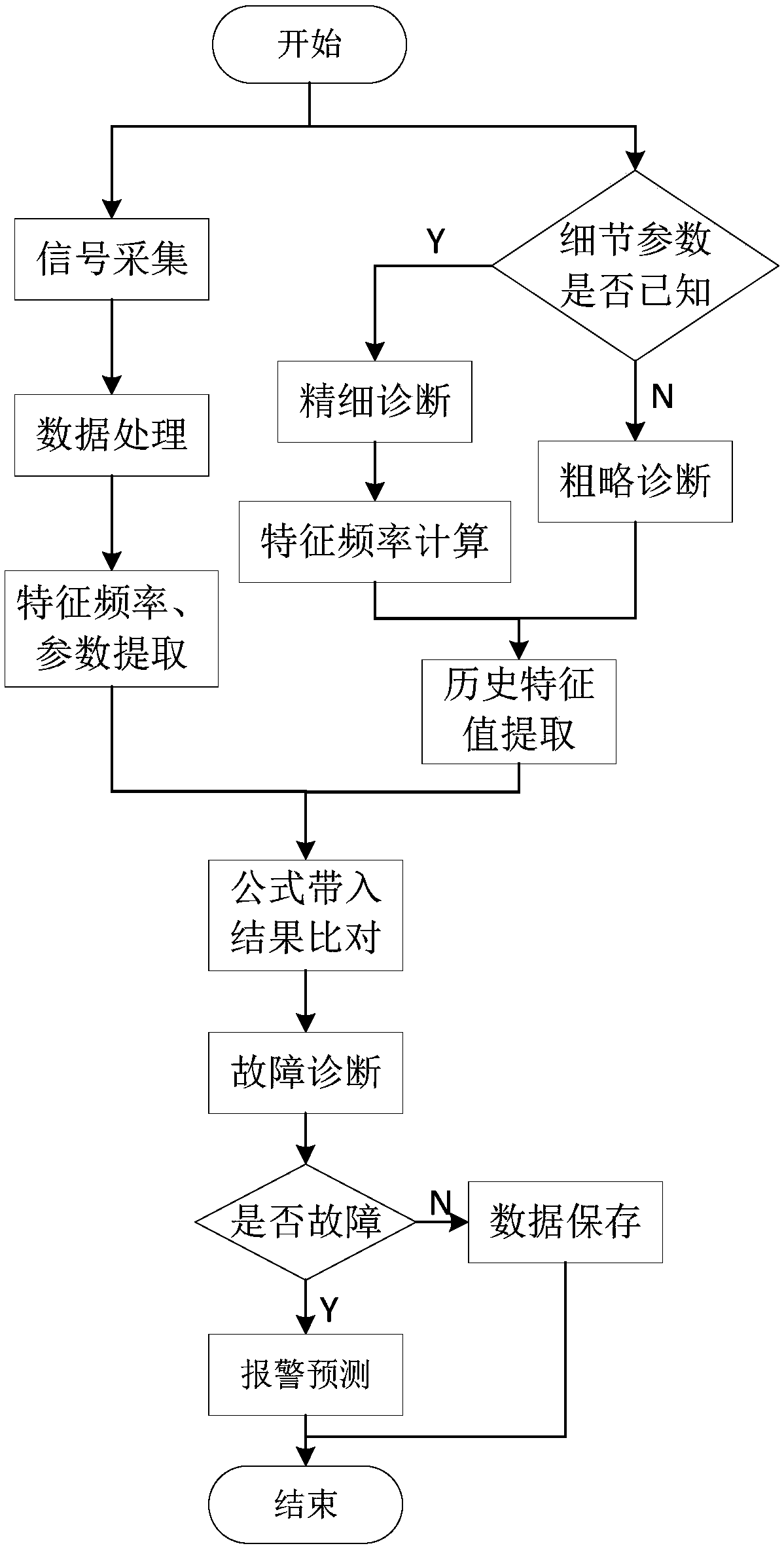

[0033] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0034] see figure 1 , an on-line diagnosis and fault early warning method for rotating machinery. Multiple vibration acceleration sensors are installed on the detected rotating machinery, and the comprehensive analysis of vibration signals at different positions is used to determine the operating status of the rotating machinery to be detected and the probability that the fault type belongs to different faults. , after comparative analysis, carry out comprehensive diagnosis, the specific steps of this diagnosis method are:

[0035] If the detailed parameters of the main components of the rotating machinery are known (the main components of the rotating machinery include rotors, bearings and gear transmission systems), fine diagnosis is selected. The concept of fine diagnosis is to calculate the corresponding frequency formula through the known detailed parameters of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com