High-stability parallel double-gate-plate gate valve

A high-stability, double-gate technology, used in sliding valves, valve devices, engine components, etc., can solve problems such as affecting the performance and service life of valves, large vibration amplitude of sealing discs, and reducing valve service life, etc., to achieve eddy current The effect of reducing shock and vibration, improving sealing performance, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

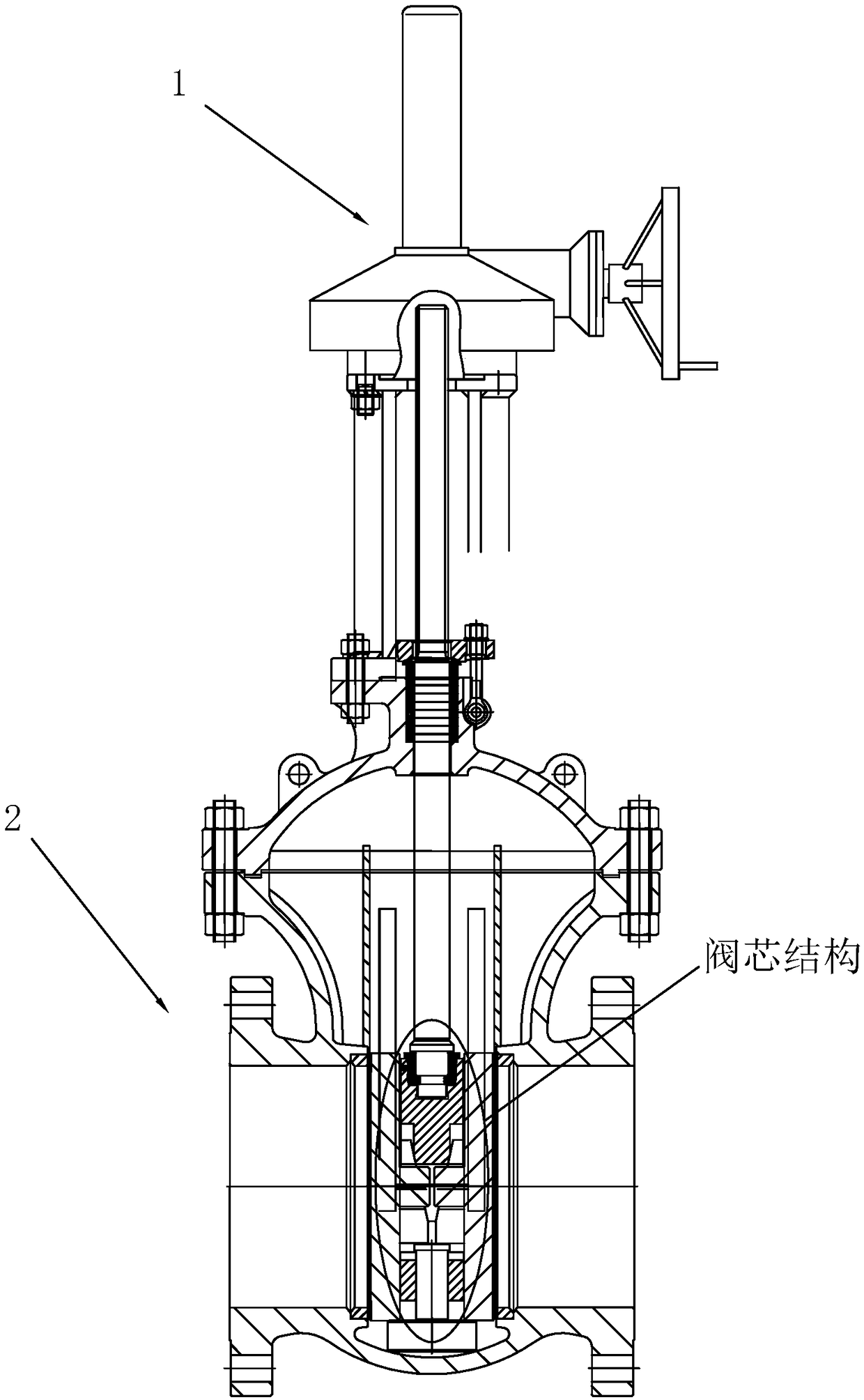

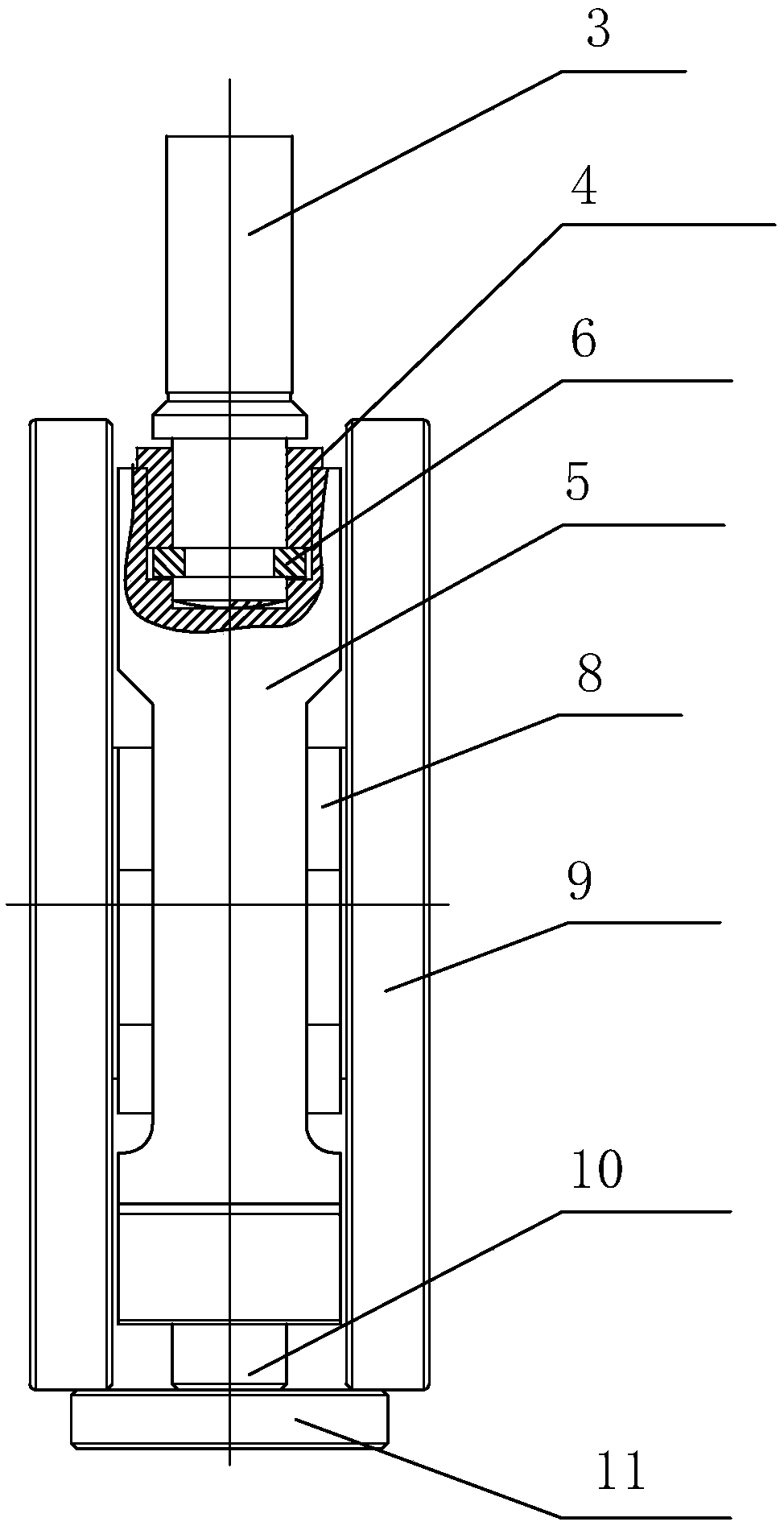

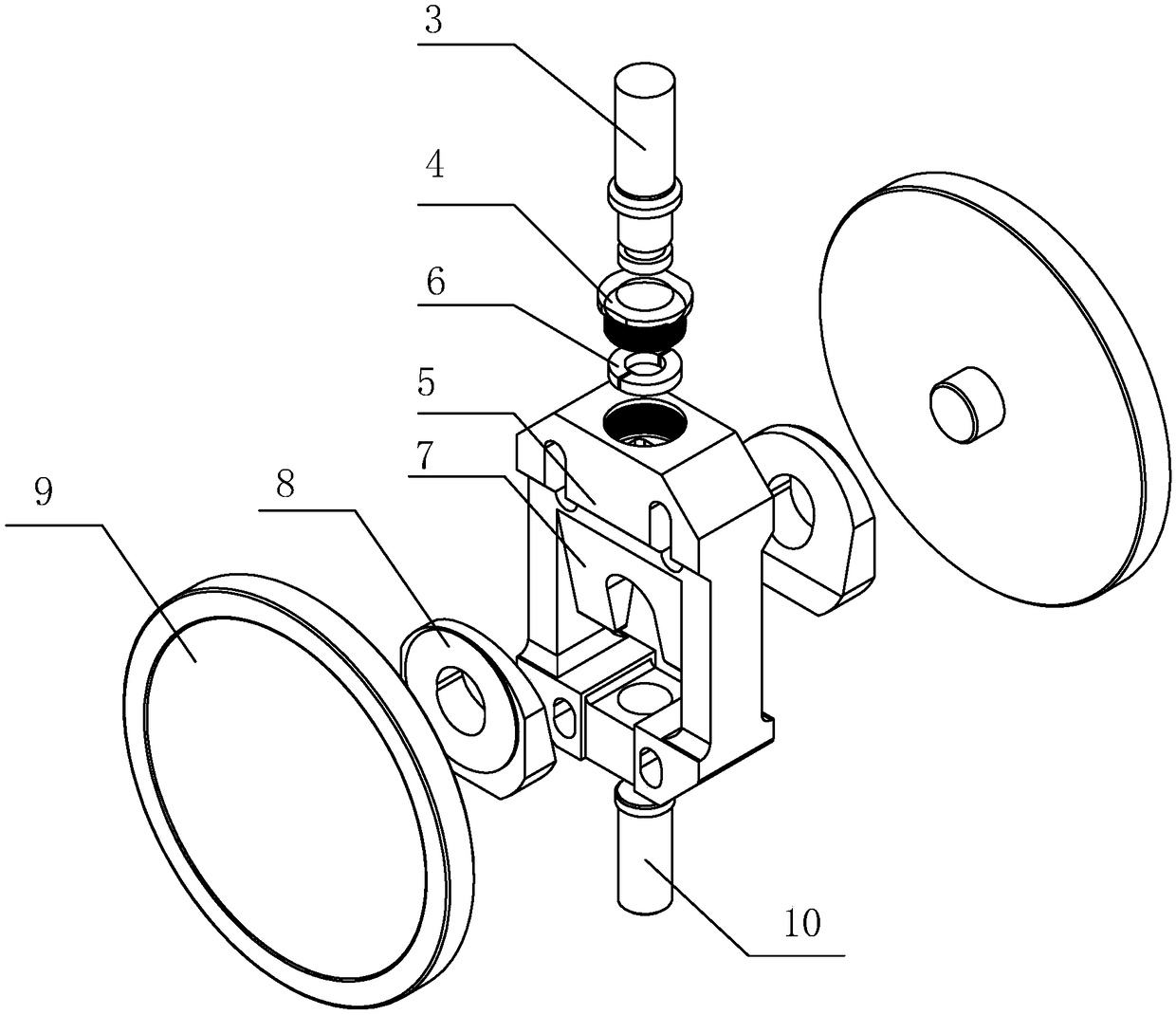

[0032] Embodiment 1: A kind of high-stability parallel double disc gate valve, such as figure 1 , figure 2 and image 3 As shown, it includes a bonnet 1 and a valve body 2, the bonnet 1 is fixedly connected to the top of the valve body 2, the valve body 2 is provided with a valve core structure, the valve core structure includes a valve stem 3, the One end of the valve stem 3 is threadedly connected with a wedge block 5 through a threaded gland 4, and a split ring 6 is arranged between the wedge block 5 and the threaded gland 4. The wedge block 5 includes a tapered surface 7 inside the wedge block 5, The wedge block 5 is provided with an expanding block 8 inside the wedge block 5 and attached to the conical surface 7, and the side of the expanding block 8 is attached to the conical surface. The expansion block 8 is connected with a sealing disc 9, the bottom of the wedge block 5 is pierced with a limit shaft 10 connected with the wedge block 5, the bottom of the valve body ...

Embodiment 2

[0042] The difference with embodiment 1 is:

[0043] The sides of the two sealing discs facing away from each other are coated with a wear-resistant composite layer. According to parts by weight, the wear-resistant composite layer includes 20 parts of silicon oxide ceramics, 20 parts of silicon carbide, 20 parts of quartz, and 55 parts of vanadium iron powder , 63 parts of ferrochromium powder, 55 parts of ferromolybdenum powder, 75 parts of ferrosilicon powder, 75 parts of ferromanganese powder, 7 parts of high elastic iron powder, 6 parts of vanadium powder, and medium carbon steel as the base material of the matrix. The thickness of the grinding compound layer is set to 4mm.

[0044]The silicon oxide ceramics, silicon carbide, quartz, ferrovanadium powder, ferrochrome powder, ferromolybdenum powder, ferrosilicon powder, ferromanganese powder, high elastic iron powder and vanadium powder are all screened to 200-300 mesh.

[0045] The wear-resistant composite layer uses 30 p...

Embodiment 3

[0052] The difference with embodiment 1 is:

[0053] The sides of the two sealing discs facing away from each other are coated with a wear-resistant composite layer. According to parts by weight, the wear-resistant composite layer includes 30 parts of silicon oxide ceramics, 30 parts of silicon carbide, 30 parts of quartz, and 60 parts of vanadium iron powder , 65 parts of ferrochromium powder, 60 parts of ferromolybdenum powder, 80 parts of ferrosilicon powder, 80 parts of ferromanganese powder, 10 parts of high-elastic iron powder, 10 parts of vanadium powder, and medium carbon steel as the base material of the matrix. The thickness of the grinding compound layer is set to 4mm.

[0054] The silicon oxide ceramics, silicon carbide, quartz, ferrovanadium powder, ferrochrome powder, ferromolybdenum powder, ferrosilicon powder, ferromanganese powder, high elastic iron powder and vanadium powder are all screened to 200-300 mesh.

[0055] The wear-resistant composite layer uses 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com