Preparation method of stock solution colored porous regenerated fibers

A technology for regenerated fiber and dope coloring, applied to artificial filaments in cellulose solution, chemical post-treatment of cellulose/protein artificial filaments, adding pigments to spinning solution, etc., can solve the problems of poor antistatic performance and moisture absorption Poor performance, accumulated static electricity and other problems, to achieve the effect of easy operation, simple process, and solve the damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

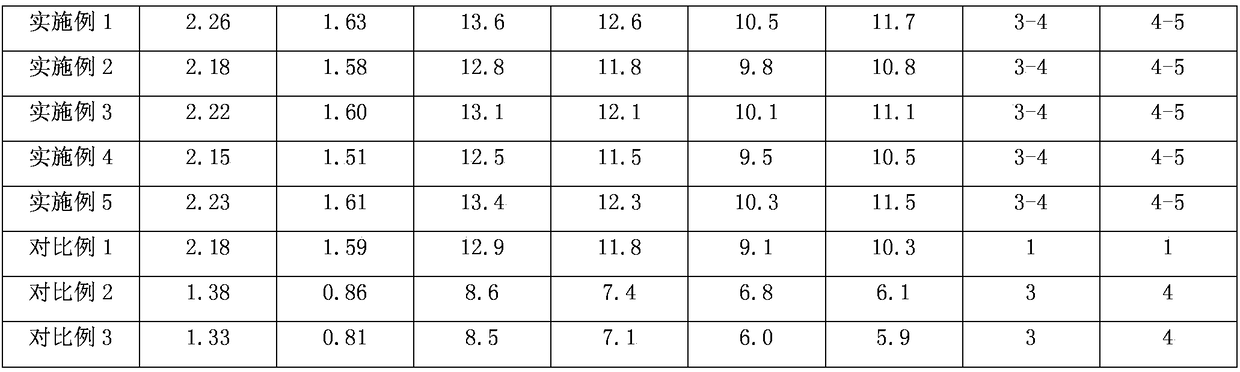

Examples

Embodiment 1

[0029] A method for preparing dope dyed porous regenerated fibers, specifically comprising the following steps:

[0030] 1) Preparation of spinning dope: Before dissolving, put the lint pulp cellulose with a degree of polymerization of 1000 in an oven at 80°C and dry until the weight is constant, then dissolve the cellulose at -10°C by 8wt% In the alkaline aqueous solution that sodium hydroxide, 2wt% lithium hydroxide and 10wt% ammonia water form, make the cellulose solution of 8wt%;

[0031] 2) Preparation of color paste: adding cinnabar with a fineness of 0.05 μm into an aqueous solution with a mass fraction of 3% polyvinyl alcohol, and ultrasonically dispersing for 5 hours to obtain a uniform color paste solution with a solid content of 30%;

[0032] 3), preparation before spinning: mix the spinning stock solution and the color paste solution into the stirring tank, the amount of the color paste is calculated as 1% based on the mass percentage of the colored solid matter in...

Embodiment 2

[0036] A method for preparing dope dyed porous regenerated fibers, specifically comprising the following steps:

[0037] 1) Preparation of spinning dope: Before dissolving, put the cotton linter pulp cellulose with a degree of polymerization of 800 in an oven at 80°C and dry until the weight is constant, then dissolve the cellulose in -5°C with 5wt% In the alkaline aqueous solution that sodium hydroxide, 3wt% lithium hydroxide and 8wt% ammonia water form, make the cellulose solution of 5wt%;

[0038] 2) Preparation of color paste: add malachite green with a fineness of 0.01 μm to an aqueous solution with a mass fraction of 1% sodium carboxymethyl cellulose, and disperse ultrasonically for 4 hours to obtain a uniform color paste with a solid content of 10% solution;

[0039] 3), pre-spinning preparation: mix the spinning stock solution and the color paste solution into the stirring tank, the amount of the color paste added is 0.5% based on the mass percentage of the colored so...

Embodiment 3

[0043] A method for preparing dope dyed porous regenerated fibers, specifically comprising the following steps:

[0044]1) Preparation of spinning dope: Before dissolving, put wood pulp pulp cellulose with a degree of polymerization of 1200 in an oven at 80°C and dry until the weight is constant, and then dissolve the cellulose at -15°C by 10wt% In the alkaline aqueous solution that sodium hydroxide, 1wt% lithium hydroxide and 12wt% ammonia water form, make the cellulose solution of 10wt%;

[0045] 2) Preparation of color paste: adding copper oxide with a fineness of 0.08 μm into an aqueous solution with a mass fraction of 5% polyvinylpyrrolidone, and ultrasonically dispersing for 3 hours to obtain a uniform color paste solution with a solid content of 50%;

[0046] 3), preparation before spinning: mix the spinning stock solution and the color paste solution into the stirring tank, the amount of the color paste is calculated as 1.5% based on the mass percentage of the colored ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com