Preparation method of aluminum-based power transmission line with anti-icing coating layer

A power transmission line, anti-icing technology, applied in coatings, anti-fouling/underwater coatings, paints containing biocides, etc., can solve the problems of not being able to achieve anti-icing, etc., and achieve low preparation costs and uniform film formation Good, simple coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

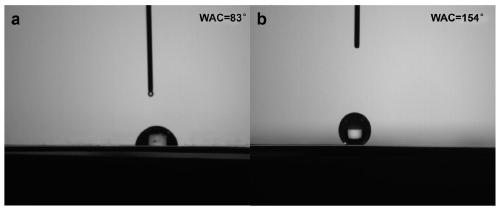

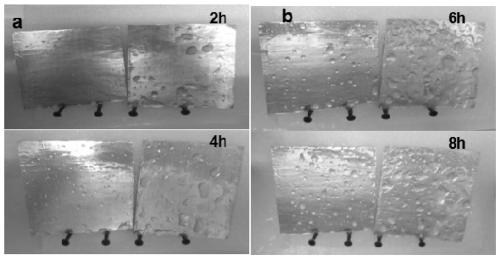

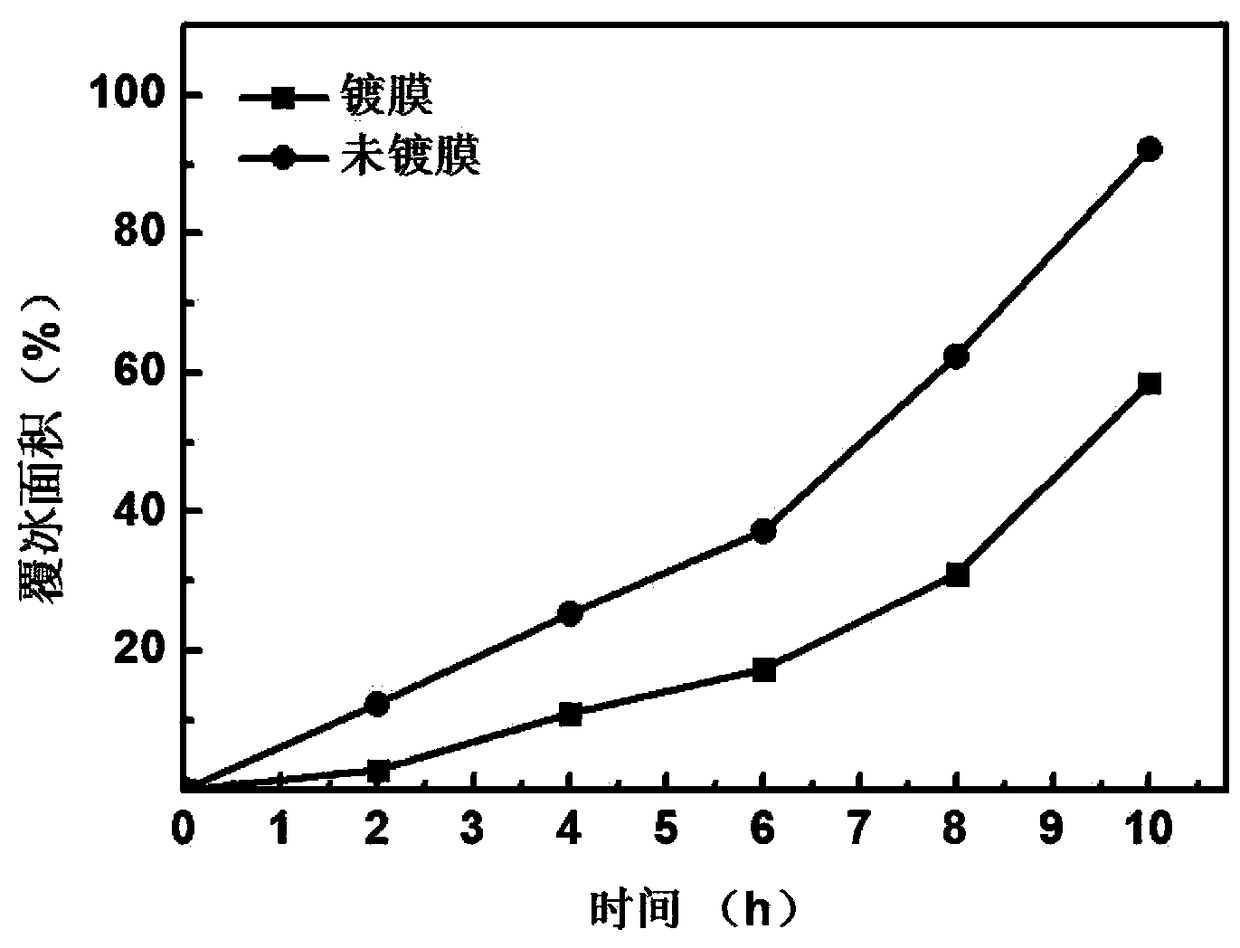

[0026] Application of anti-icing coating on aluminum sheet

[0027] (1) Preparation of PMMA solution: Add 0.5g of polymethyl methacrylate (PMMA) into 20ml of acetone to dissolve, and stir with a glass rod until PMMA is completely dissolved;

[0028] (2) Preparation of hydrophobic modification solution: put 1.5ml of hexadecyltrimethoxysilane, 5ml of water and 43.5ml of IPA in a 100ml beaker, and stir magnetically at a constant temperature of 35°C for 30 hours;

[0029] (3) Preparation of silica sol: mix 1ml TEOS, 10ml IPA, 1ml H 2 O was added to the beaker, and the mixed solution was adjusted to pH = 10 with ammonia solution, then stirred immediately at 45°C for 12 h, and then aged at room temperature for 3 days; then PMMA solution was added to it, and a uniform solution was obtained after magnetic stirring for 30 min. Sol;

[0030] (4) Preparation of anti-icing coating solution: Mix 10ml of prepared hydrophobic solution and silica sol mixed with PMMA solution to prepare anti...

Embodiment 2

[0036] Application of anti-icing coating on aluminum wire

[0037] (1) Preparation of PMMA solution: Add 0.5g of polymethyl methacrylate (PMMA) into 20ml of acetone to dissolve, and stir with a glass rod until PMMA is completely dissolved;

[0038] (2) Preparation of hydrophobic modification solution: put 2ml of hexadecyltrimethoxysilane, 6ml of water and 50ml of IPA in a 100ml beaker, and stir magnetically at a constant temperature of 45°C for 30 hours;

[0039] (3) Preparation of silica sol: mix 0.7ml TEOS, 10ml IPA, 1ml H 2 O was added to the beaker, and the mixed solution was adjusted to pH = 10 with ammonia solution, then stirred immediately at 40°C for 12 h, and then aged at room temperature for 5 days; then PMMA solution was added to it, and a uniform solution was obtained after magnetic stirring for 30 min. Sol;

[0040] (4) Preparation of anti-icing coating solution: Mix 10ml of prepared hydrophobic solution and silica sol mixed with PMMA solution to prepare anti-ic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com