Asphalt pavement assembled rapid repair technology interlayer adhesive material and preparation method thereof

A technology of asphalt pavement and bonding materials, which is applied in the field of road engineering materials, can solve the problems that road bonding materials are not suitable for use, and achieve the effects of short opening time for traffic, simple construction and good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Asphalt pavement assembly type rapid repair technology interlayer bonding material is composed of three groups of materials A, B and accelerator. The ratio of the three groups of materials is A:B:accelerator=100:30:7 according to the mass ratio;

[0037] Group A consists of the following raw materials according to mass percentage:

[0038] Bisphenol A type epoxy resin 90%;

[0039] nano-SiO 2 10%.

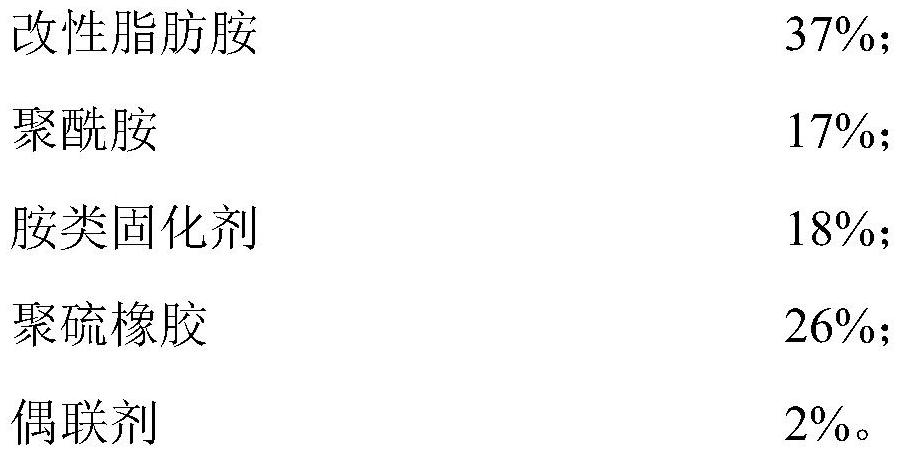

[0040] Wherein, the B group material is composed of the following raw materials according to the mass percentage:

[0041]

Embodiment 2

[0043] Asphalt pavement assembly type rapid repair technology interlayer bonding material is composed of three groups of materials A, B and accelerator. The ratio of the three groups of materials is A:B:accelerator=100:35:5 according to the mass ratio;

[0044] Group A consists of the following raw materials according to mass percentage:

[0045] Bisphenol A type epoxy resin 95%;

[0046] nano-SiO 2 5%.

[0047] Wherein, the B group material is composed of the following raw materials according to the mass percentage:

[0048]

Embodiment 3

[0050] Best practice:

[0051] Asphalt pavement assembly type rapid repair technology interlayer bonding material is composed of three groups of materials A, B and accelerator. The ratio of the three groups of materials is A:B:accelerator=100:33:6 according to the mass ratio;

[0052] Group A consists of the following raw materials according to mass percentage:

[0053] Bisphenol A type epoxy resin 93%;

[0054] nano-SiO 2 7%.

[0055] Wherein, the B group material is composed of the following raw materials according to the mass percentage:

[0056]

[0057] In group A, add nano-SiO 2 filler, due to nano-SiO 2 Large specific surface area and high surface energy show extremely high activity, and nano-SiO 2 The surface is covered by a large number of organic groups, which improves the compatibility with the organic matrix, enhances the adhesion between the nanoparticles and the epoxy matrix, facilitates the transfer of stress, can bear a certain load, consumes impact e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com