Preparation method of membrane capacitive deionization electrode and membrane capacitive deionization electrode

An electro-adsorption and electrode technology, which is applied in the field of water purification, can solve the problems of low electrode desalination efficiency, high energy consumption, affecting the normal use of electrodes and industrial promotion, etc., to reduce migration and diffusion resistance, simple preparation process, and reduce the same ion effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

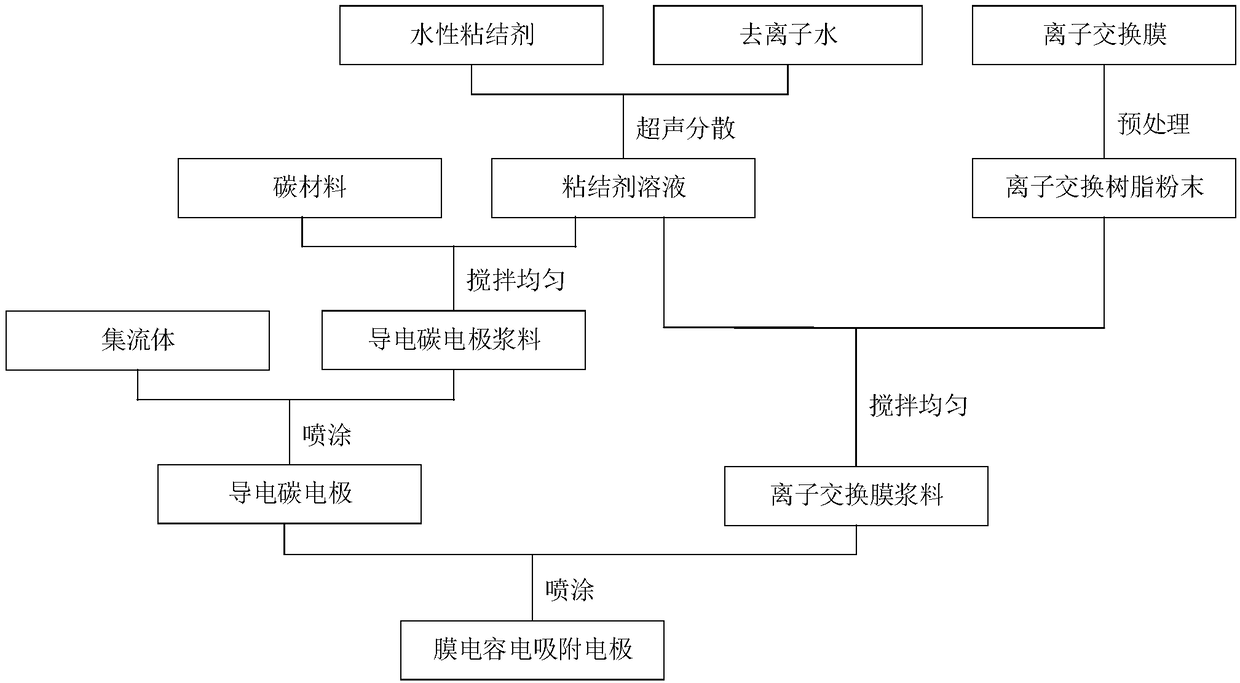

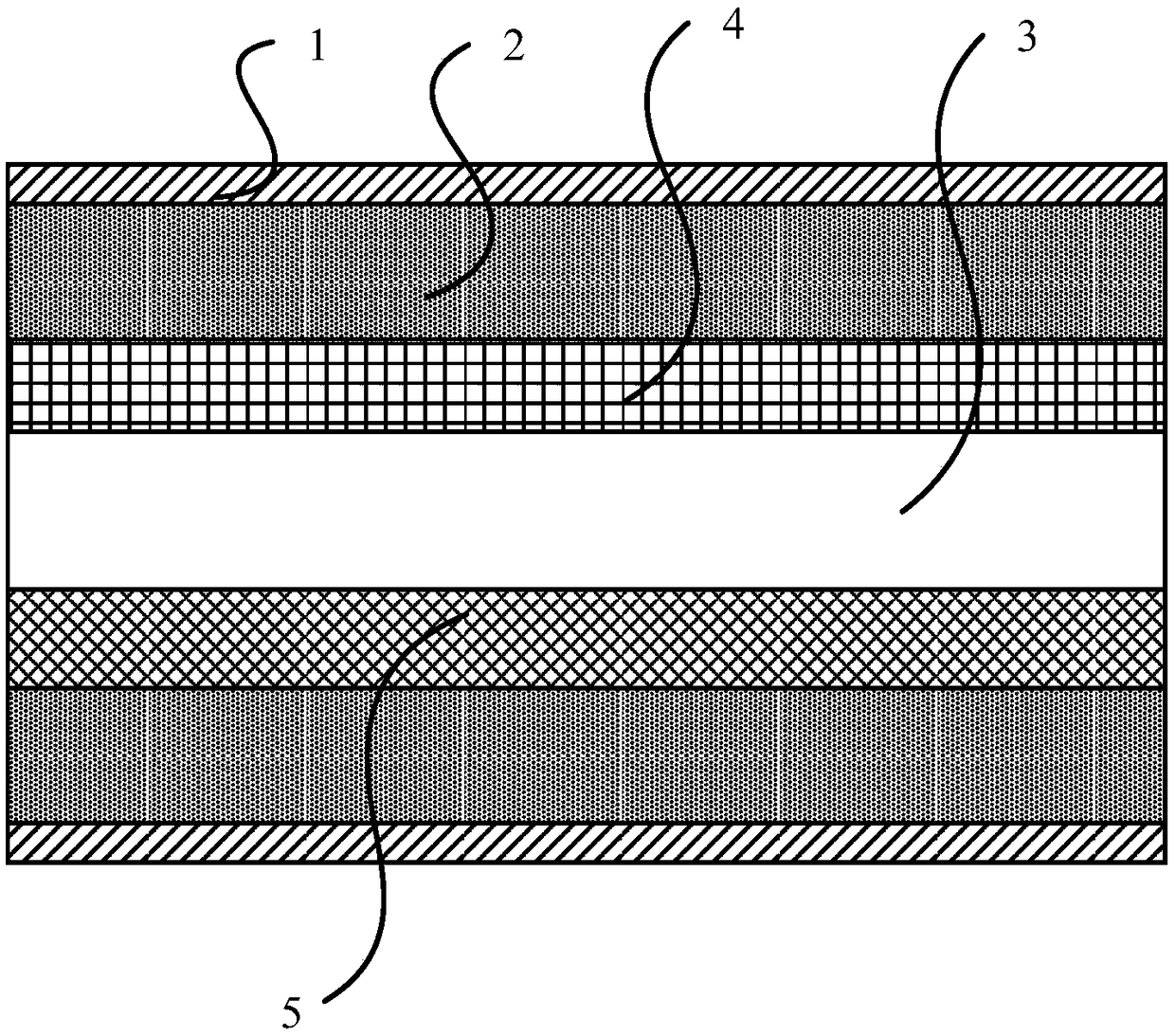

[0021] Such as figure 1 As shown, the present embodiment 1 provides a preparation method of an electrode, comprising: preparing conductive carbon electrode slurry and ion exchange membrane layer slurry respectively; preparing conductive carbon electrode through conductive carbon electrode slurry; ion exchange membrane layer slurry The material is sprayed on the surface of the conductive carbon electrode; and vacuum-dried to obtain the membrane capacitor electro-adsorption electrode. The specific operation is as follows:

[0022] (1) Get 3g of sodium carboxymethyl cellulose and add 200ml of deionized water to ultrasonic 2h to obtain a uniform aqueous binder solution (or binder solution), and then combine 3.4g of graphene with 13.6g of carbon nanotubes Add it to the aqueous binder solution and stir for 3 hours at a speed of 300r / min under an electric mixer to obtain a conductive carbon electrode slurry. After sieving through a 200-mesh screen, vacuum pumping to remove the mixed...

Embodiment 2

[0026] (1) Take 3g of sodium carboxymethylcellulose and add 200ml of deionized water for ultrasonication for 2h to obtain a uniform aqueous binder solution, then add 4.25g of graphene and 12.75g of carbon nanotubes to the aqueous binder solution Stir for 3 hours at a speed of 300r / min under an electric mixer to obtain a conductive carbon electrode slurry, sieve through a 200-mesh screen, and then vacuum pump to remove the air bubbles in the mixed solution (conductive carbon electrode slurry), and finally the conductive carbon electrode slurry The electrode slurry was sprayed on the surface of graphite paper to obtain two identical conductive carbon electrodes.

[0027] (2) Take 20 g of anion and cation exchange resins and crush them into powdery resin powders with a vibrating mill, and wash them with deionized water repeatedly for 5 times. First soak the cleaned cation exchange resin powder in 0.1M NaOH solution completely, then use deionized water to filter and wash repeatedl...

Embodiment 3

[0030](1) get the polyvinyl alcohol of 3g to add the deionized water ultrasonic 2h of 200ml to obtain uniform aqueous binder solution, then the graphene of 5.7g and the carbon nanotube of 11.3g are joined in the aqueous binder solution, in Stir with an electric mixer at a speed of 300r / min for 3 hours to obtain a conductive carbon electrode slurry, sieve through a 200-mesh screen, and then vacuum pump to remove the air bubbles in the mixed solution (conductive carbon electrode slurry), and finally the conductive carbon electrode slurry The material was sprayed on the surface of graphite paper to obtain two identical conductive carbon electrodes.

[0031] (2) Take 20 g of anion and cation exchange resins and crush them into powdery resin powders with a vibrating mill, and wash them with deionized water repeatedly for 5 times. First soak the cleaned cation exchange resin powder in 0.1M NaOH solution completely, then use deionized water to filter and wash repeatedly until neutral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com