Environment-friendly multifunctional ostomy bag

A multi-functional, ostomy bag technology, applied in the direction of colostomy, drainage, coating, etc., can solve the problems of patients' odor, etc., and achieve the effects of easy spraying, good anti-corrosion, and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

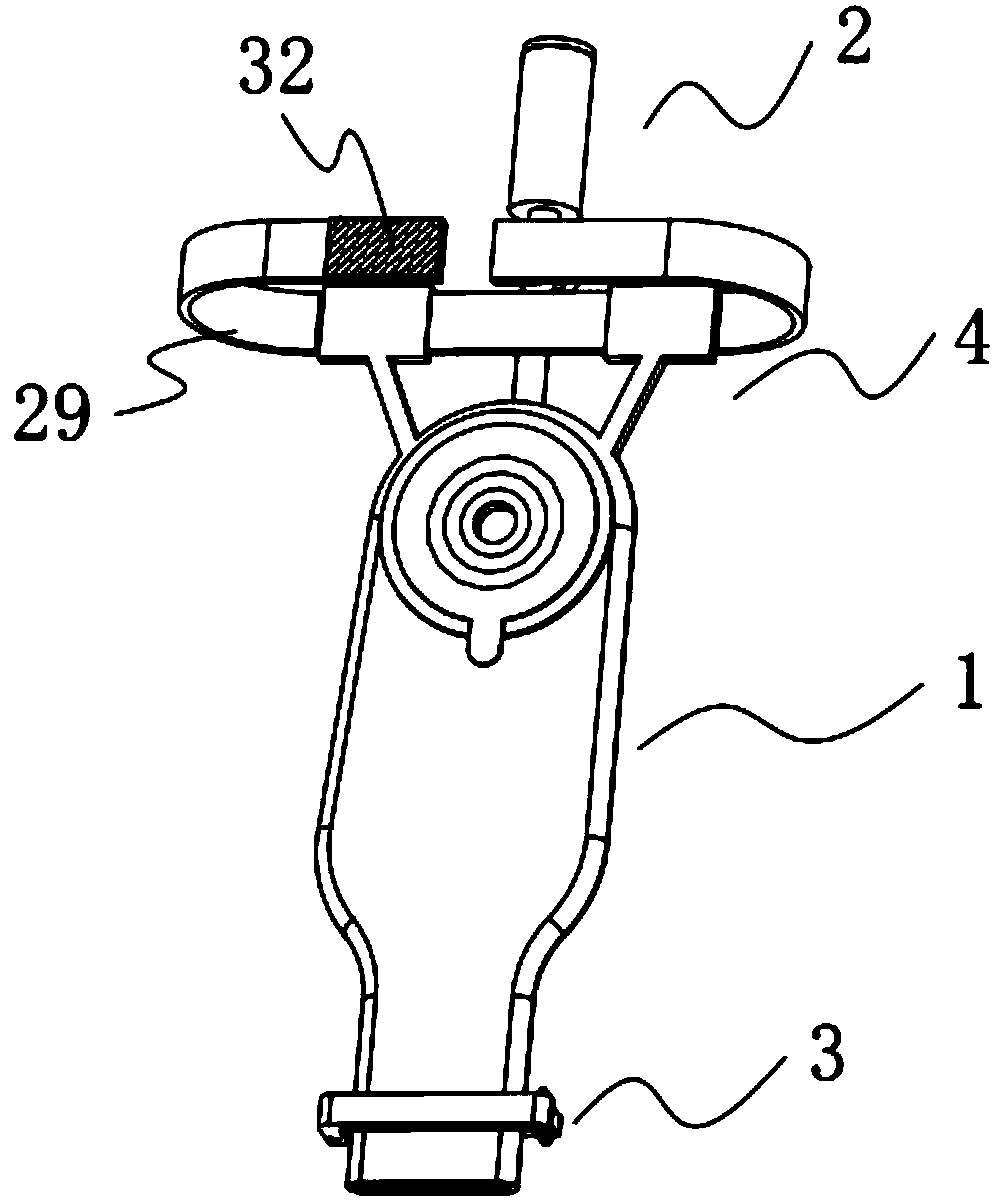

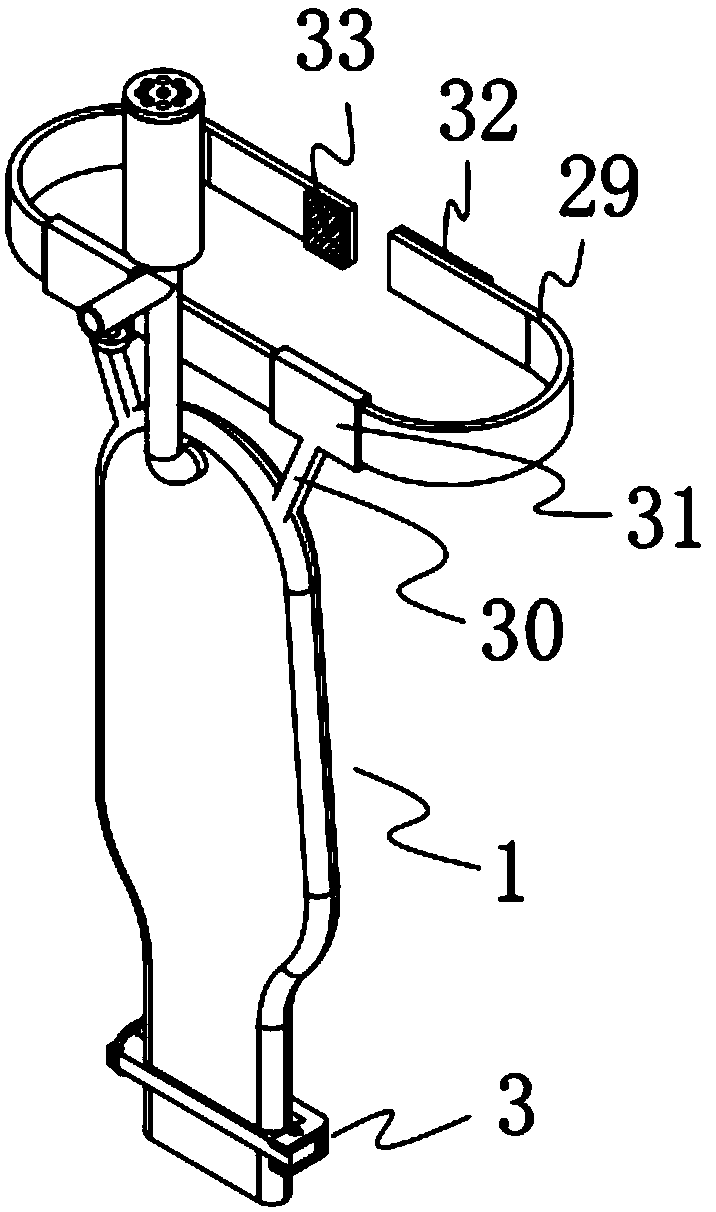

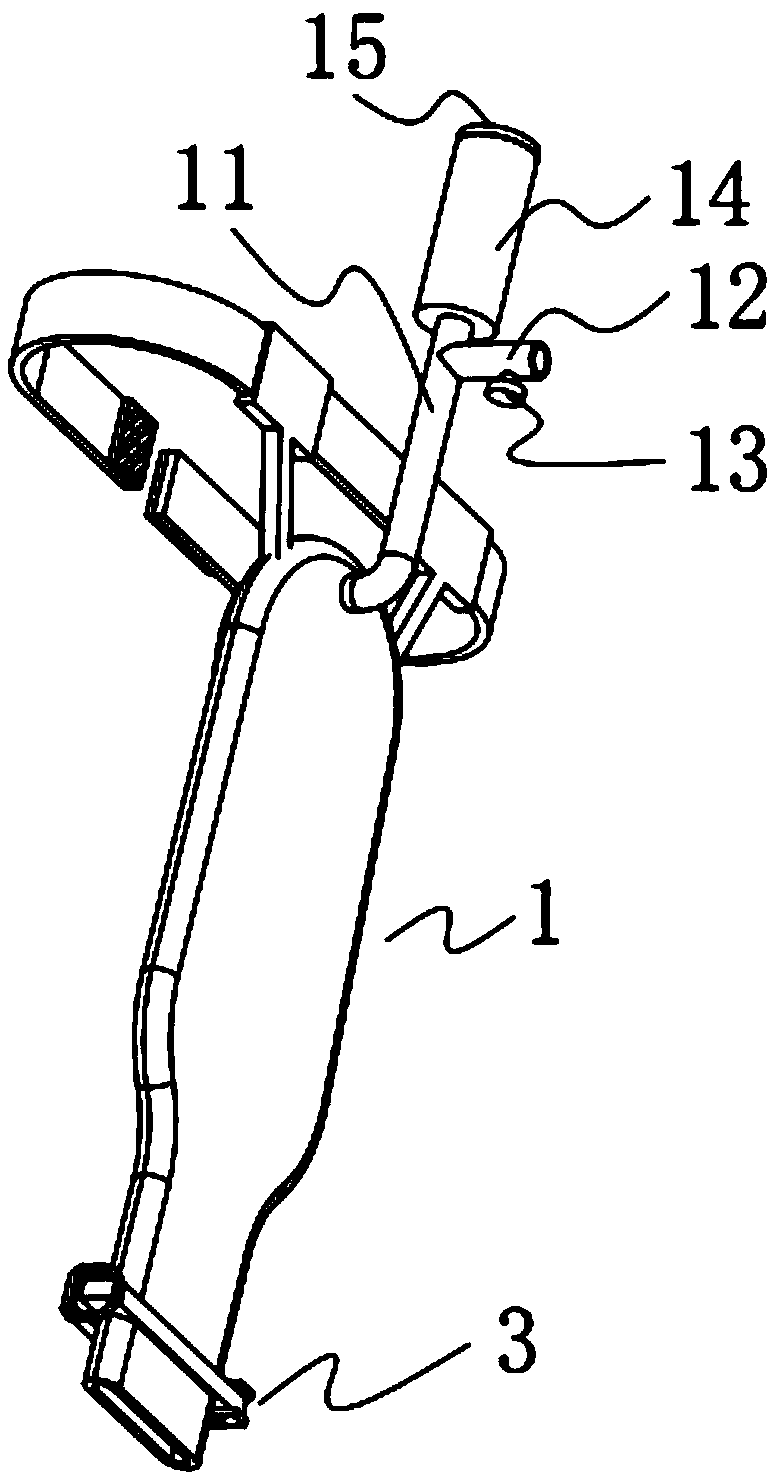

[0061] An environment-friendly multifunctional ostomy bag, such as Figure 1-3 As shown, it includes a collection part 1, a prompt part 2 and a sealing part 3;

[0062] Such as Figure 5-6 As shown, the collection part 1 includes a bag body 5, one end of the bag body 5 is a closed end, and the other end of the bag body 5 is an open end, and the side surface of the bag body 5 near the closed end is inlaid There is a circular film 6, and a release protective paper 7 is pasted on the outer surface of the circular film 6;

[0063] Such as image 3 , 4 , 7 and 8, the prompting part 2 includes a first hose 11 whose one end communicates with the other side of the bag body 5 close to its closed end, and the other end of the first hose 11 communicates with a round A cylindrical housing 14, and a second hose 12 is connected to the first hose 11 at a position close to the cylindrical housing 14, and a valve 13 is installed on the second hose 12, so The inside of the cylindrical hous...

Embodiment 2

[0083] The difference from Example 1 is that the inner surface of the bag body 5 is also provided with a protective layer, and the protective layer is prepared by the following method:

[0084] Take the following raw materials and weigh them by weight: 20 parts of polytetrafluoroethylene particles, 8 parts of zinc oxide powder, 12 parts of silver powder, 10 parts of copper rosinate, 10 parts of spices, 3 parts of glycerin, 5 parts of alcohol ester twelve, high carbon 1 part of alcohol fatty acid ester complex and 30 parts of water;

[0085] S1. Add the weighed copper rosinate, glycerin, alcohol ester dodeca, higher alcohol fatty acid ester complex and water into the mixer and stir for 20min at a stirring speed of 600r / min to prepare a mixed solution;

[0086] S2, adding polytetrafluoroethylene particles, zinc oxide powder, silver powder and spices into a mill for grinding until the diameter of the particles is not greater than 40um to obtain a mixed powder material;

[0087] ...

Embodiment 3

[0092] The difference from Example 2 is the preparation of the protective layer, and its specific preparation method is as follows:

[0093] Take the following raw materials and weigh them by weight: 25 parts of polytetrafluoroethylene particles, 9 parts of zinc oxide powder, 14 parts of silver powder, 11 parts of copper rosinate, 12 parts of spices, 4 parts of glycerin, 6 parts of alcohol ester twelve, high carbon 2 parts of alcohol fatty acid ester complex and 40 parts of water;

[0094] S1. Add the weighed copper rosinate, glycerin, alcohol ester dodeca, higher carbon alcohol fatty acid ester complex and water into the mixer and stir for 25min. The stirring speed is 700r / min to prepare a mixed solution;

[0095] S2, adding polytetrafluoroethylene particles, zinc oxide powder, silver powder and spices into a mill for grinding until the diameter of the particles is not greater than 40um to obtain a mixed powder material;

[0096] S3. Put the mixed solution prepared in step S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com