RC capacitor automatic assembly machine

An automatic assembly machine and capacitor technology, which is applied in packaging capacitor devices, capacitors, capacitor manufacturing, etc., can solve the problems of time-consuming, labor-intensive, high-cost, and low production efficiency in production methods, improve production quality and pass rate, and meet the needs of large-scale production. Production, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

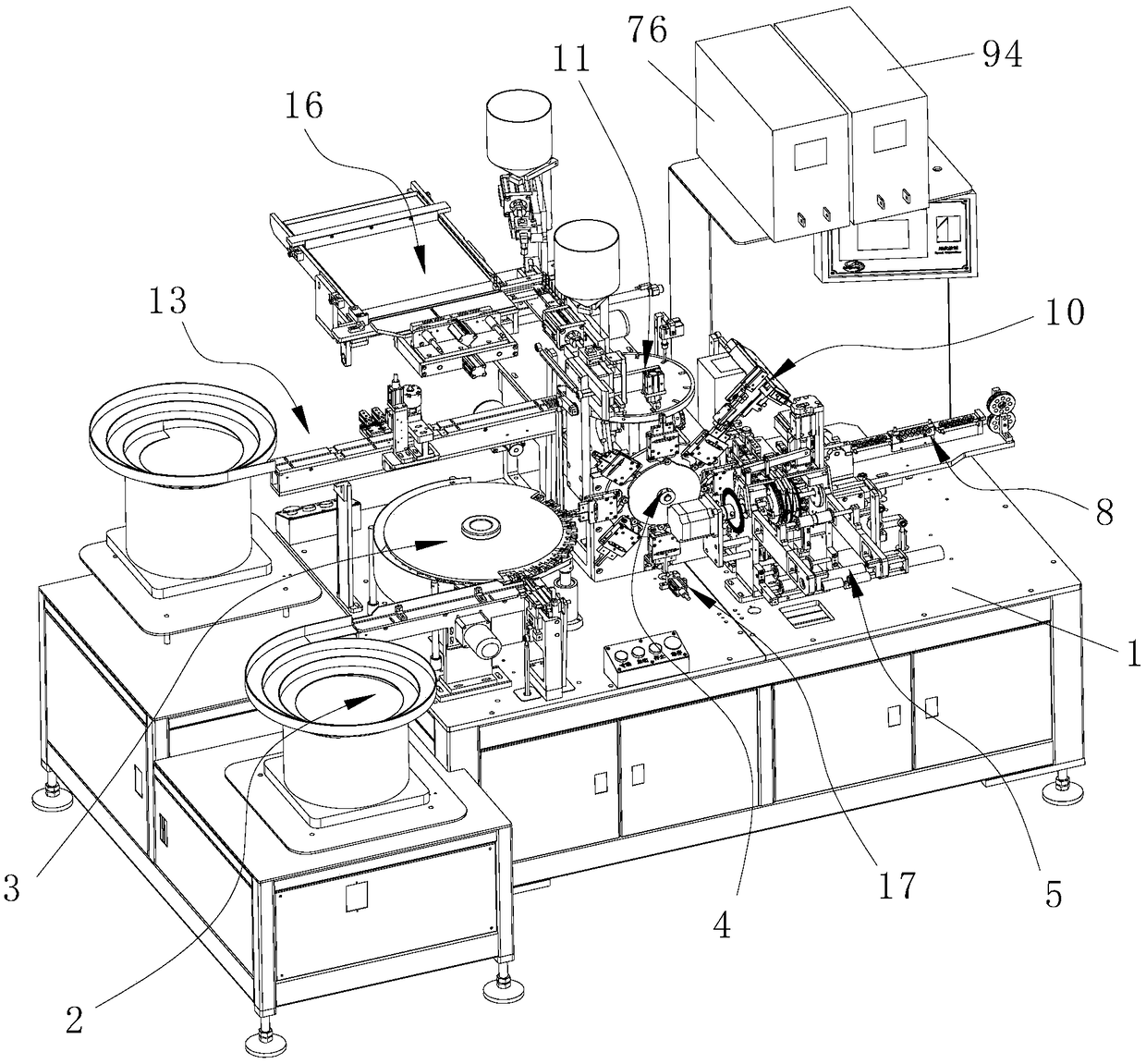

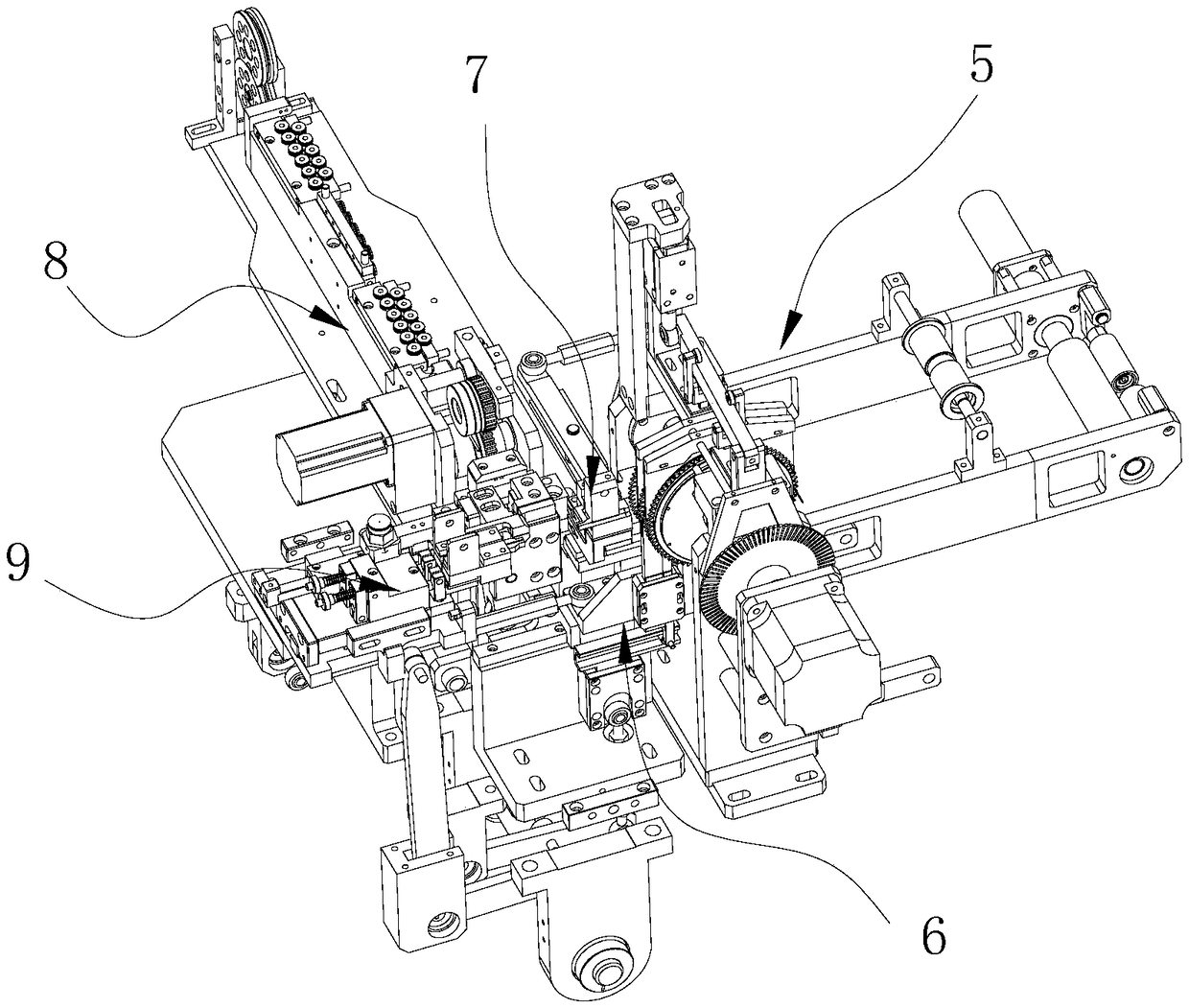

[0043] Please refer to figure 2 , image 3 and Figure 4, the embodiment of the present invention provides an RC capacitor automatic assembly machine, including a frame 1 and a capacitor element mounted on the frame 1 for providing capacitor elements and transporting them to the turntable element energy distribution mechanism 3 Feeding mechanism 2. Used to energize the capacitor element and transport the capacitor element material to the element disc clamping operation mechanism, the turntable type element energy distribution mechanism 3. Used to clamp the capacitor element on the vertical surface to realize the station conversion 4. Resistor stripping and cutting mechanism for cutting resistors from the resistor strip 5. Resistors for clamping and transferring the cut resistors to the side of the capacitor element at the welding station Clamping and feeding mechanism 6, a resistance welding mechanism 7 for welding a connection wire of the resistor to one side of the capaci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com