Contour error estimation method based on H-shaped precision movement platform

A precision motion and contour error technology, applied in the direction of instruments, digital control, control/regulation systems, etc., can solve the problems of increased estimation error, inappropriateness, long calculation time, etc., and achieve the effect of reducing contour error and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

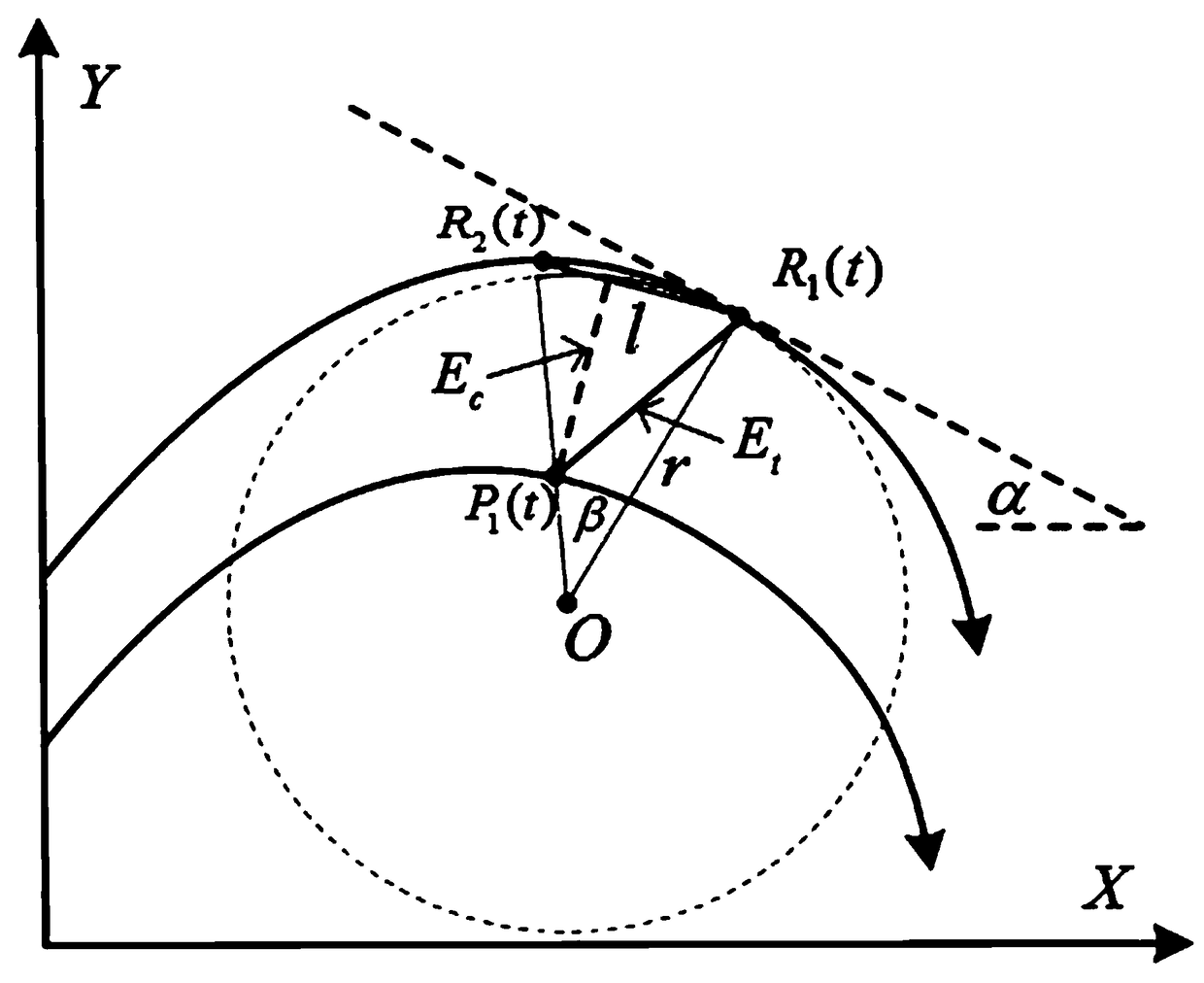

[0045] Specific implementation mode 1: The real-time contour error estimation model of any trajectory is as follows figure 1 As shown, R 1 (t) is the desired trajectory position; R 2 (t) obtains the reference point on the desired track for reverse deduction; P 1 (t) is the actual motion track position; E t is the contour tracking error; O and r are respectively over R 1 (t) The center and radius of the inscribed circle; l is the arc length corresponding to the angle β; 1 The angle between the tangent line at point (t) and the X axis. Contour estimation error E c for P 1 (t) to line R 1 (t)R 2 (t) distance.

[0046] Step 1: Calculate at the reference point R 1 The curvature ρ and curvature radius r at (t) are as follows:

[0047]

[0048] in, for the desired machining profile in R 1 (t) the slope when the Y axis is the independent variable; for the R 1 The second derivative at (t) with the X axis as the independent variable.

[0049] Step 2: Calculate R 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com